Such drilling changes dimensions and everything loads/unloads far faster than at HRCK, similar to the HRCK's product like assembly conveyor. If you use normal methods to load and unload, it can be very slow sometimes. Through the use of our drilling technology, we are able to complete these jobs in a timely manner with minimal mess and inconvenience.

We do novel little drills to put holes in the small cargo containers on corners, just like the wood loading gantry factory manufactured by HRCK. The reason for this is it will leave us with 6 points to pick up and drop the cargo. Loading time and unloading which was previously hours of time can now be done in minutes. That saves a huge amount of time, crucial in the fast-paced world of shipping. This not only accelerated the process but kept the load secure too. Lifting the cargo this-evenly in all 6 surfaces will significantly reduce risk of breaking or damaging anything. This translates to less stress for all parties and ensures the items we are transporting are safe.

Now, due to our innovation in drilling technology everyone can experience the ease of cargo on wheels, same with HRCK's gantry palletizer. Until we developed this technology, workers had to do one of these pieces on at a time. It was very time-consuming and as a result often held up the delivery guide-lines which nobody likes. We have moved many such pieces thanks to our special drilling. This saves not only time, but also allows employees to be significantly more efficient. The biggest thing is that it can carry a lot more at once, which will get everyone done quicker and operation running better.

The way cargo is moved from one place to another has genuinely been revolutionised through our drilling technology, just like the wood line produced by HRCK. Bonus Auto Save features are? It saves us time not only when we are shipping cargo out or in but also when carting it On location from one spot to another. And this, in turn can lead to faster deliveries. This gives customers a better user experience since they get their wares sooner and are very happy about it. Customers are what keep companies in business, so ensuring that they leave your establishment satisfied is key in order to have a good reputation.

Rent-drilling Here at HRCK, we are extremely proud of our newly acquired drilling technology, also the HRCK's product such as wood stacking machine. It has greatly improved the cargo handling of transportation industry. Empowering cost reduction, making work easier and keeping customers happy. We dive on the positive developments that we have introduced to this industry which inspires us for more innovation and work towards improving such aspects in times ahead. We hope to inspire more examples of this kind as we drive the advancement in cargo-tech so you can ship easier and safer for everyone involved.

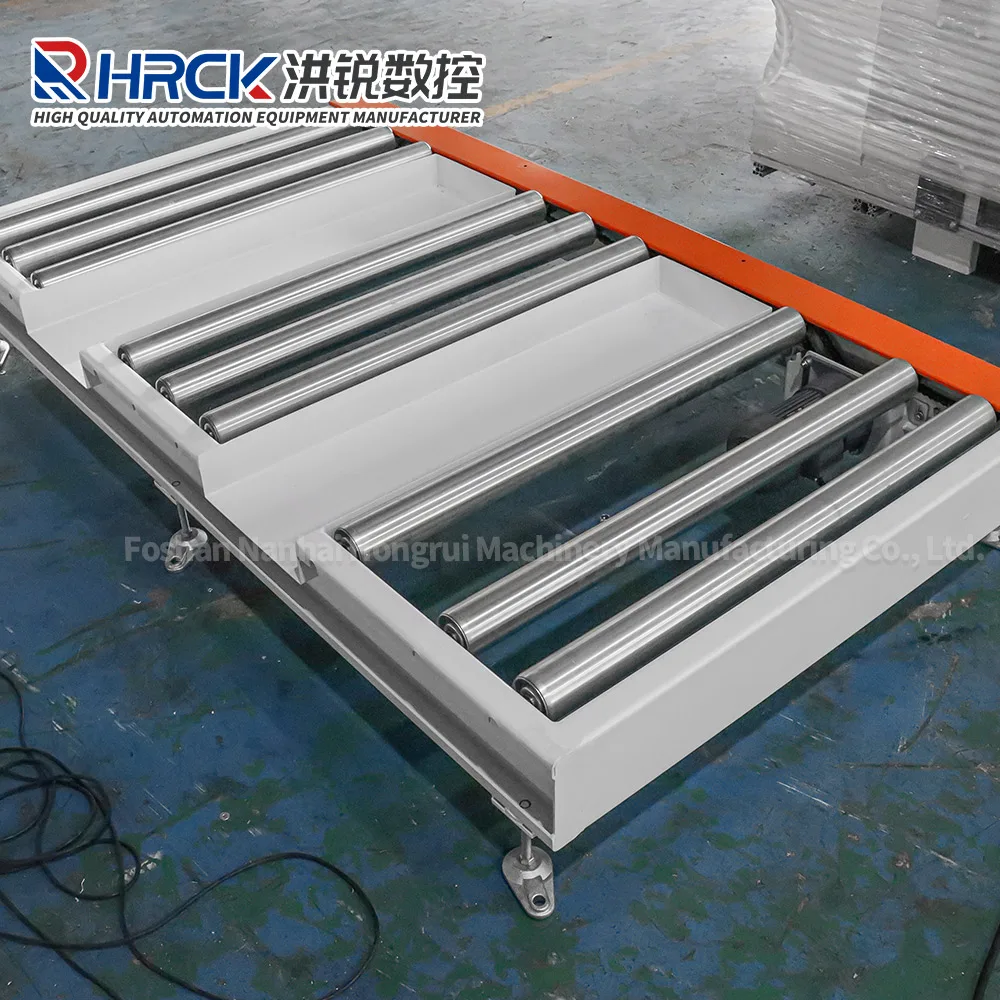

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of manufacturing automation technology. With over a decade's experience, we have a specialization in developing, manufacturing, and constructing a broad range of automation solutions, including conveyor belts as well as roller lines and gantry feeders. Our products are constantly improved and we launch new products every year to keep up with the ever-changing needs of the market. Our commitment to quality is reflected in our Six sided drilling for loading and unloading, TUV, SGS, and ISO certifications, ensuring the highest standards of quality and performance. You will benefit from our top-of-the-line technology and products that maximize efficiency and high-quality.

We provide a wide range of after-sales services that include installation commissioning as well as maintenance Our service staff is experienced and responds swiftly to address any issues that may arise during operation With a global support network We provide Six sided drilling for loading and unloading support and solutions no wherever you are We're committed to providing efficient and professional support that guarantees the reliability of your equipment This will enhance production efficiency and customer satisfaction We are attentive to your needs and work to exceed your expectations with every service that we provide

We have accumulated a vast amount of experience in the field of Six sided drilling for loading and unloading within Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on offering customized automation solutions, tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team has a thorough understanding of the specific challenges and requirements for woodworking production. Based on years of industry experience, we design and provide efficient, reliable automation solutions that increase efficiency in production as well as product quality. Our expertise does not just assist clients to optimize their production processes, but tackles many technical issues that are specific to industry making sure that each equipment is fully compatible with woodworking needs. Our woodworking experts can help your production line gain an edge by offering expert assistance.

More 10 engineers collaborate to develop innovative products that keep up market dem s provide customized solutions that meet the specific requirements continuously improving products research into technology Our strong RD capabilities not only advance technology but also keep edge in the market deliver efficient reliable automation solutions that break the boundaries of traditional technology leading Six sided drilling for loading and unloading trends This ensures the highest performance for every product create