If you have ever seen a movie that shows a factory, you may have seen a conveyor belt in it. Traveller is an important machine, used to transport the things in a flow. Instead it uses pulleys and belts to move things from where they are to where they need to be. Now, with the modern technology, a factory roller conveyor automated is a special type of conveyor. If possible, this type of conveyor belt because it is more independent, as it eliminates the need for a person to manipulate it. Now, we discuss the advantages of an automatic conveyor belt in the factories.

One notable example is an automated conveyor belt which can transport things quicker than human beings. This is crucial because it controls that products be created rapidly, assisting with diminishing postponements. Some customers receive products sooner when products are made faster, making everyone happy. And the conveyor belt can place items more precisely than people can. Getting a product into the right spot is critical, because when connecting products with processes, if a product can’t get placed appropriately, things don’t get built correctly and can lead to issues. In addition, the automated conveyor belt could also save factories a lot of money because it required fewer workers to operate it. That means factories can make more products while spending the same — or less — amount of money.

One of the main benefits of an gantry crane is that it can always hold products in the necessary position when needed. In manufacturing, timing is everything. We don't want to have parts that are not in the right place at the right time, because it may cause delays, and in worst case scenario, we cannot finish a product. We can produce products quicker and with more efficient way because an automated conveyor belt ensures that all the components in the right place at the right time.

When we say output, we mean the amount of products we can produce in a defined time period. It also helps to maximize our output used an automated conveyor belt. It consists of many types of machines that work collectively to create products. One main component in this system is the conveyor belt, but there are other machines that help in product manufacturing.

Doing so should be even faster with the use of an automated conveyor belt system. This is possible since each of the machines in the system is fit to work with each other, thus increasing the speed of the production process. This is not just allowing us to develop more products, but also enabling us to create better products. This is crucial as customers want products that are high-quality and dependable.

Having introduced automated conveyor technology, we can guarantee worker safety. An automated conveyor belt is capable of moving items without requiring humans to touch them. This means that workers will not be injured or killed at work. Automated conveyor technology not only increases safety but also adds precision. The machines are built to work in harmony, so products are built precisely as they ought to be. That's why, when it comes to manufacturing, precision is key. Products must meet certain specifications in order to be fit for their purpose.

This system, for example, can product faster than any other one. By producing products more quickly, products are received faster to customers that make them very happy. In addition, a high-tech automated conveyor belt system can be tailored to the specific requirements of each factory. One that works optimally for the specific needs of each factory. Lastly, implementing a sophisticated automated conveyor belt system can provide factories with long-term savings of their significant finances. Because of this, and the system is designed to be more efficient, so it would use up less resources and would need less maintenance.

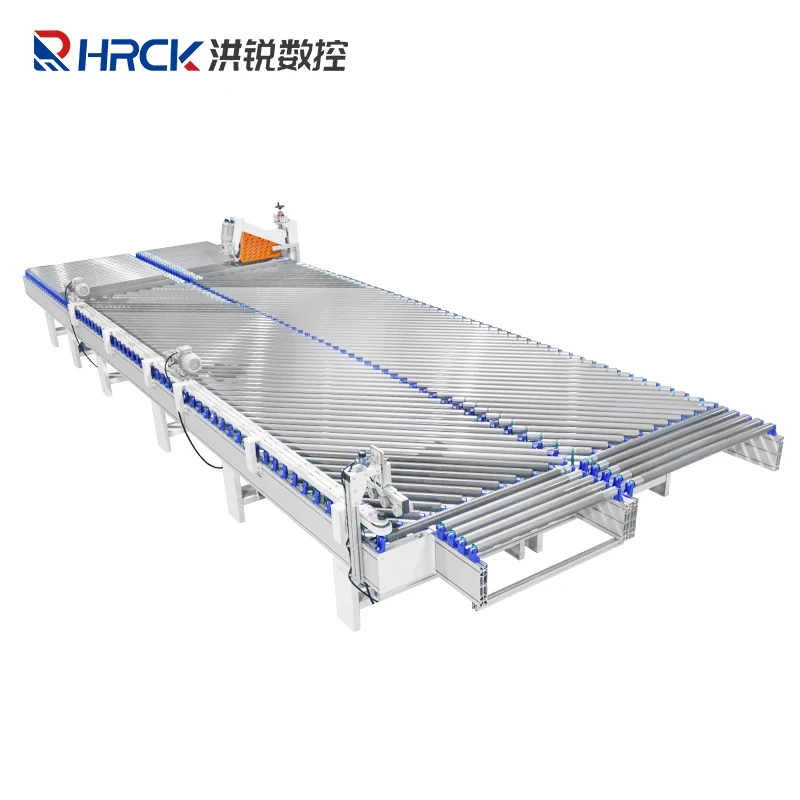

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of technological advancements in the field of factory automation. We have more than automated conveyor belt of expertise developing, manufacturing and installing automation solutions, such as belt conveyors and roller lines. Our products are continually upgraded and we launch new products every year to keep up with the ever-changing needs of the market. Our ISO, TUV and SGS certifications show our commitment to quality, and guarantee the highest standards in reliability and performance. When you choose us, you benefit from top-notch technological support and products designed to maximize efficiency and quality.

automated conveyor belt extensive after-sales services we offer include installation of the system, commissioning it and maintaining. Our expert service team responds promptly to any issues that may arise while operating. With a global support network We provide prompt tech support and solutions no regardless of where you're located. We're dedicated to providing professional and efficient service that will ensure the long-term reliability of your equipment. This will increase production efficiency and customer satisfaction. Our services are designed to meeting your needs. We strive to surpass expectations.

In Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have built substantial expertise in the woodworking industry. Since our beginnings we've been a leader in offering customized automation solutions, tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well understanding of the specific challenges and requirements of woodworking production. With years of experience in the industry, we design and provide efficient, reliable automation systems which improve efficiency of production and product quality. We don't just assist clients to enhance their processes but we also address many specific industry issues. Every system is compatible with the requirements of woodworking. Work with us to receive an automated conveyor belt assistance within the woodworking industry and give your production line an edge over competitors.

Over 10 engineers work together to create innovative products that align to market dem offer customized solutions to meet specific needs through continuous product improvements research into technology keep edge extensive RD capabilities deliver reliable efficient automation solutions breaking the boundaries of conventional technology leading technological trends This ensures the highest performance of every product automated conveyor belt