In woodworking, have you ever watched someone make a cabinet? Just one cabinet would take lots of hard work and weeks to make. Just think about how long it would take to build dozens of cabinets individually! You now know how to start on a big order of cabinets but there is another way. An automatic cabinet HRCK wood production line is for workers making cabinets, it means they can make a lot more in less time.

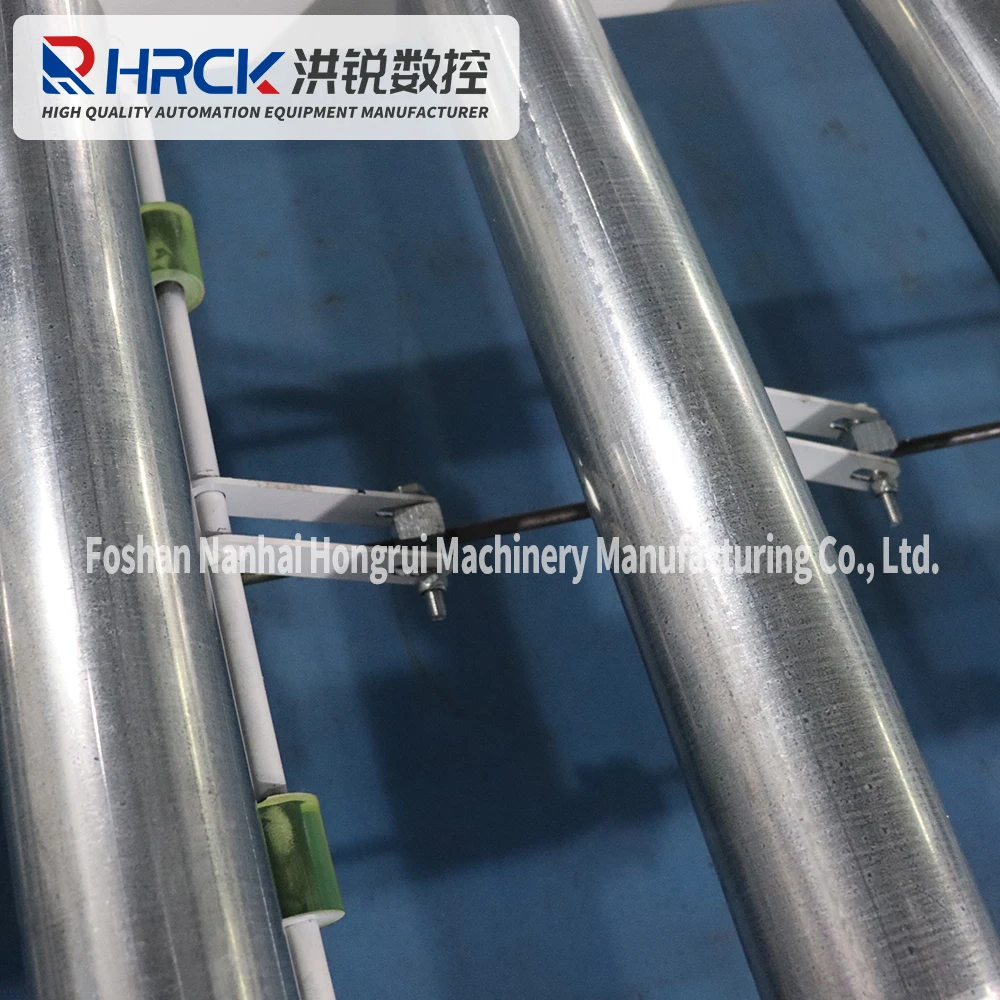

Making cabinets that involves the use of machines and not only our hands is termed as an automatic cabinet production line. This means the HRCK home furniture production line does much of the work instead of all being done by a person. This helps to reduce labor times and expenses, while also keeping the cabinets consistent in appearance over time. The pieces of wood are then cut to the right size on a computer. Special machines will then assemble the parts together. Then, the cabinets get sanded down and sprayed to look smooth and beautiful again.

An automatic cabinet production line will help to produce more cabinets quicker. This way will make the cabinets much faster and with fewer mistakes. This translates to an ability for companies who use it within their product line offering, being able to produce far more cabinets than would otherwise be possible in a given time frame and they can make more money. The HRCK wood production machinery will also work constantly 24/7 without the need for rest like people. By not needing to stop production the process will even improve its efficiency.

The following is a quick guide to developing your own kind of automatic cabinet production line. The First thing that you have to do is plan over how will you manage your production line. Consider how big your purse is, who takes much space you have in the work area and kit of machines. Then, buy the Production line solutions and install them in your shop. Even after the machines are installed, you would need to verify that they function properly and safely. After all, once you set everything up, we have a fresh new business rolling through and were off to the races making cabinets!

In the automatic production line, when making cabinets, pay special attention to controlling it. Keep in mind the following tips: Check if machines are set up properly to begin with. This is designed to ensure that the pieces are cut and assembled in order. Check the machineries and maintain them properly. A wood production line is like a car and it has to be treated with the same level of care. Train your staff on how to employ the machines properly so that they can troubleshoot any glitches. By simply adhering to these principles, you can optimize the efficiency and reliable quality of your automatic cabinet production which will result in high-quality kitchen cabinetry that customers rave about.

Our extensive after-sales assistance includes installation of the system commissioning it and maintaining Our expert service team is quick to resolve any issues that may Automatic cabinet production line while operating With a global network of support and a rapid response time to tech support and solutions no matter where you are We are committed to providing professional and efficient service that will ensure the long-term reliability of your equipment This improves efficiency in production and ensure satisfaction for customers We are attentive to your needs and work to exceed your expectations with every service that we offer

We have accumulated a vast amount of experience in the field of Automatic cabinet production line within Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on offering customized automation solutions, tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team has a thorough understanding of the specific challenges and requirements for woodworking production. Based on years of industry experience, we design and provide efficient, reliable automation solutions that increase efficiency in production as well as product quality. Our expertise does not just assist clients to optimize their production processes, but tackles many technical issues that are specific to industry making sure that each equipment is fully compatible with woodworking needs. Our woodworking experts can help your production line gain an edge by offering expert assistance.

Automatic cabinet production line has been at the forefront of manufacturing automation for more than 10 years. We have over 10 years of expertise developing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are constantly refined and come up with new ideas every year to meet the ever-changing needs of our customers. Our commitment to quality is evident in our ISO, TUV, SGS, and ISO certifications. They guarantee the highest standards of quality and performance. When you work with us, it is possible to get top-quality technological support and products specifically designed to enhance efficiency and quality.

Over 10 engineers work together to create products that comply market requirements can tailor solutions to meet client dem s through continual product improvement as as technological research Our Automatic cabinet production line RD capabilities not only improve product technology but also maintain leading position in the field provide reliable effective automation solutions that push the boundaries of conventional technology cutting-edge technological trends This ensures optimal performance for every product develop