A conveyor belt is a specific kind of machine that transports goods from one location to another. These types of belts are used in factories, to help work be done more quickly. Rather than having employees haul heavy boxes or parts from area to area, the conveyor belt moves this product for them. That means workers are focused on assembling rather than moving pieces and parts around.

Gets more items done quickly: The conveyor belt moves items in a steady manner, allowing workers to assemble them without spending time. They do not have to stop working on their jobs to pick things up. We speed-up the whole process through this.

Making life easier for workers: For example, it’s hard and sometimes hazardous to carry heavy objects. When workers are required to lift or move heavy boxes, they can become fatigued or injured. The items can be transferred in a more comfortable and safer way thanks to the conveyor belt. It does the heavy lifting for the workers so they can do their jobs without overexerting themselves.

Quality checks: It is easier for workers to perform quality checks on know right next to the conveyor belt when items are transported on the conveyor belt. They can examine each item as it passes. If they see any issues or problems, they can quickly address them before they go too far down the line.” This ensures that whatever products are made are high quality.

Belt alignment: When the belt is not aligned correctly, products can get stuck or even fall off. Belt should remain straight, so 1-2 times a month it needs to be checked and adjusted. Now you are trained on dates until October 2023.

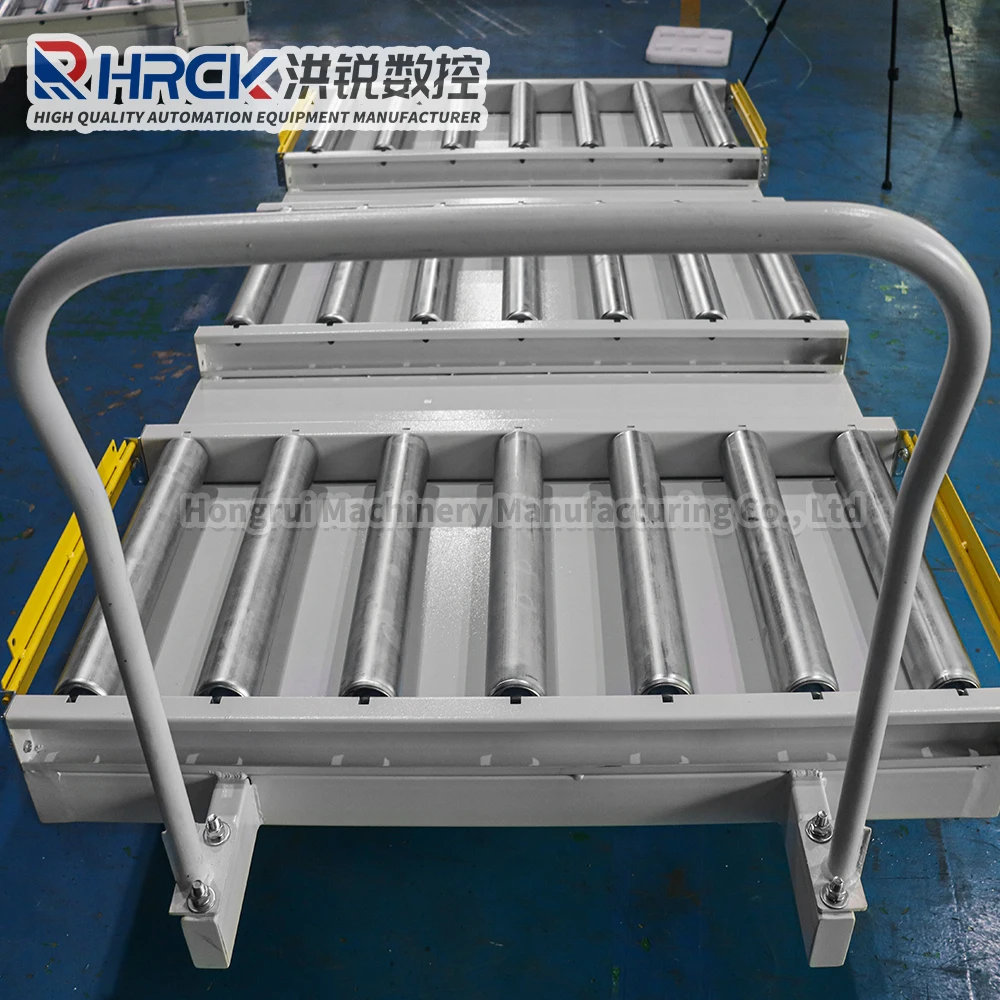

Physical wear: Over time, the conveyor belt parts such as belts, rollers and chains can wear out. Routine checks should be done to see if they have worn down and need to be replaced. Worn out items should be replaced so the conveyor keeps flowing smoothly.

Using robots can help make factories even more efficient. Machines work faster and they execute the tasks with precision and no fatigue. They don’t require breaks, so they can work all day long. This can allow factories to make more products in less time and reduce labor costs.”

We provide convayor line after-sales services such as installation, commissioning and maintenance. Our skilled service team responds quickly to any issues that arise while operating. We have a global support network that enables us to offer timely solutions and technical support, regardless of where you might be. Our dedication to dependable and efficient service guarantees the long-term stability and reliability of your equipment, improving productivity and customer satisfaction. We are attentive to your needs and strive to exceed expectations with every service we provide.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of manufacturing automation technology. With over a decade's experience, we have a specialization in developing, manufacturing, and constructing a broad range of automation solutions, including conveyor belts as well as roller lines and gantry feeders. Our products are constantly improved and we launch new products every year to keep up with the ever-changing needs of the market. Our commitment to quality is reflected in our convayor line, TUV, SGS, and ISO certifications, ensuring the highest standards of quality and performance. You will benefit from our top-of-the-line technology and products that maximize efficiency and high-quality.

convayor line have accumulated a large quantity of expertise in the field of woodworking within Foshan Nanhai Honorgrui Machinery Manufacturing Company Ltd. Since our inception, we have specialized in delivering customized automation solutions tailored to the particular requirements of woodworking processes, including conveyor systems, processing equipment and more. Our team is familiar with the demands and difficulties of woodworking production. We create and implement efficient and efficient automation systems that increase production efficiency and the quality of products. Our knowledge of the industry does not just assist clients to optimize their production processes, but tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Partner with us for assistance in the woodworking industry that will give your line of production an edge.

More 10 engineers collaborate to develop innovative products that keep up market dem s provide customized solutions that meet the specific requirements continuously improving products research into technology Our strong RD capabilities not only advance technology but also keep edge in the market deliver efficient reliable automation solutions that break the boundaries of traditional technology leading convayor line trends This ensures the highest performance for every product create