If you ever worked with your parents to fix a piece of furniture, you may have heard about something called edge banding. Edge banding is a crucial process that involves applying a thin strip of material to the edges of the furniture. This not only beautifies the furniture but also conceals any rough or sharp edges present. READ: This process may look easy but it actually requires quite a lot of time and effort to do it properly. Enter HRCK and their specific conveyor table line for edge banding.

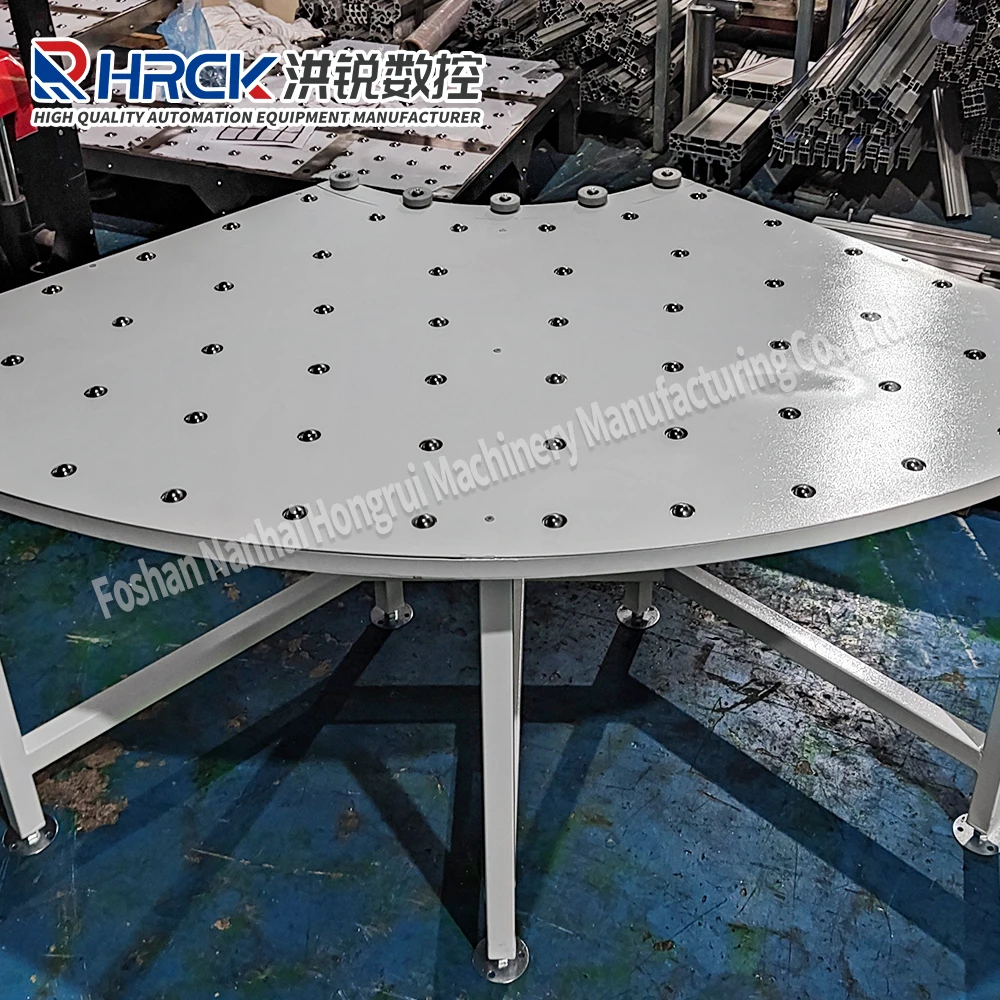

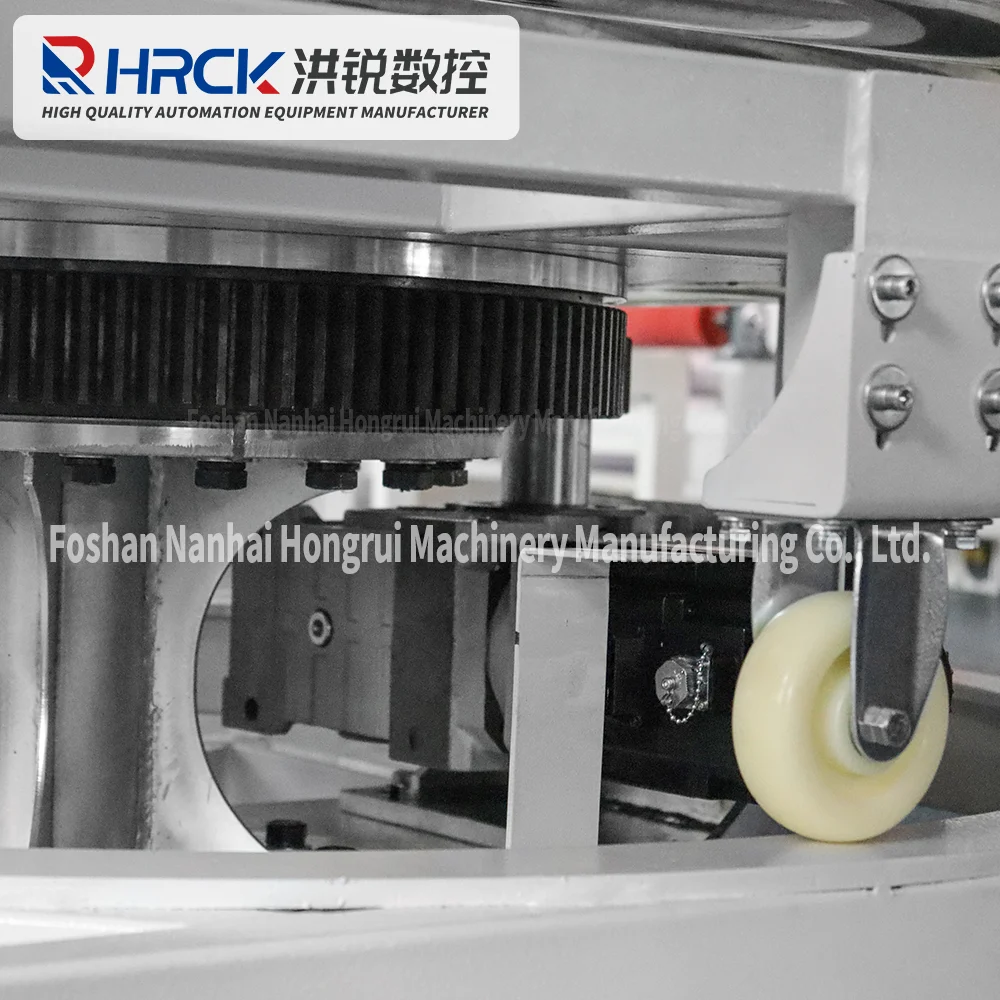

An edge banding conveyor table is quite a useful tool that provides a lot of ease and makes the edge banding process much faster. The manual process of applying edge banding material to the furniture piece is painstaking and tiring, so a piece of furniture is placed on a conveyor belt that pulls it through a machine known as an edge bander. As a result, it is used quickly and efficiently, which saves time and ultimately reduces expenses, allowing companies to work more efficiently and manufacture more furniture in a given time period.

There is not a workshop that serves to repair or make furniture that does not have a conveyor table for edge banding. This tool is really useful as it helps you save time and money. By using the conveyor table, it applies the same amount of material, so each piece of furniture looks good and is built well. A lot of the great feature of the conveyor belt is that it is adjustable. It means that it has a capacity to fit the huge and little things, which makes it a greatly beneficial machine to have in the workshop.

Edge banding is an essential process that plays a significant role in the look of the final piece of furniture. The use of a conveyor table for edge banding guarantees excellent results time after time. It is also applied evenly, making the edges of the furniture look smooth and clean. And this way no one shall see any rough edges or uneven spots which can give an unprofessional look to the furniture. If done well, edge banding is often the single biggest factor in determining whether people consider the furniture well-made.

Finally, useful time and money by also using a conveyor table for your edge banding. Whereas a large number of workers are needed to apply the material by hand to each shoe, the conveyor belt does the heavy lifting. This allows you to do the entire procedure much more rapidly and needs less employees which is perfect for businesses, where the cost needs to be moderate. Ultimately, this process creates a beautiful ready-to-use furniture piece.

Our conveyor table line for edge bander after-sales support includes installation, commissioning and maintenance. Our expert service team responds promptly to any issues that may arise in the course of operating. We offer a worldwide support network that allows us to provide prompt solutions and technical support, no matter where you may be. Our commitment to prompt and professional service ensures the long-term, stable operation of your equipment, improving efficiency and satisfaction of customers. Our services are geared towards fulfilling your requirements. We are determined to meet or exceed expectations.

We conveyor table line for edge bander developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.

conveyor table line for edge bander 10 engineers collaborate to create products that align market requirements With continuous technological research product enhancements provide customized solutions tailored to specific client requirements Our strong RD capabilities not only advance technology but also keep leading position in the marketplace offer reliable efficient automation solutions breaking the boundaries of traditional technology cutting-edge technological trends This guarantees optimal performance for each product develop

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront in factory automation technology for over a decade. We have over 10 years of experience in designing, manufacturing and installing automation solutions, such as belt conveyors and roller lines. We constantly improve our products and introduce innovative solutions annually to meet evolving market demands. Our ISO, TUV and SGS certificates reflect our dedication to quality, and guarantee the highest standards in reliability and performance. When you work with us, it is possible to get top-quality technological support and equipment designed to conveyor table line for edge bander effectiveness and quality.