HRCK stands for HR CurvedKool roller conveyor systems. They help raise precautions with advanced technologies and systems that simply need to cover a distance and do their job, moving one material to the other destination. The conveyor belt is of a propriety design; it is rainbow-shaped. This curve enables goods to slide down the belt instead of getting stuck or obstructed. A bent conveyor is able to hold a range of big and small items. It can also transport cases of boxes, bags, as well as machine components. It also helps to minimize the chances of damaging or breaking any of the materials as they carry along the gantry crane.

Curved conveyors are very special for the companies to transport their products in higher speed. What seems like an indifferent to attempt to make use of space enables the vacuum wood stacker to take corners without any issues, or slowing down. It progresses the merchandise slowly and softly whenever they're set on the conveyor belt. That allows them to navigate that curve without tipping over or going off the side. It is done in such a way products remain safe reaching the end customer without any hassle. These are particularly useful in crowded spaces, where a lot of things are constantly in motion.

One advantage of curvilinear conveyor technology is that it allows companies to maximize their space utilization. Whatever type the conveyor is a straight conveyor is consuming a lot of space as compared to a curved conveyor. So, that frees up space for something else. For instance, a business may use the additional space to store a larger number of goods or to enable workers to move more freely. Curved conveyors are also designed with close proximity to your building walls. This smart design encourages the use of space to maximize the amount of materials and products that a company can store without cramping their movement.

Curved conveyor is that provides difference in place HRCK With curved conveyor, products can continue moving along the belt without pause. This is quite a useful feature, as it saves having workers spend additional time transporting items manually. Instead, the conveyor does the work for them. The curved conveyor can even be configured to move products automatically to designated areas. Workers don't have to be involved in every step of the process, which keeps them safe and lessens the likelihood of accident. In the end, this smoothens and accelerates the work process!

Safety is paramount in any workplace, and curved conveyors work to contribute to the safety of everyone. This 3D model is a curved conveyor designed with a smooth belt, which helps prevent injury to workers. The flat surface of the belt means fewer opportunities for getting stuck and creating an incident. The conveyor belt is normal self-cleaning as well. Thus, it may assist in keeping the products clean and free from dirt or germs that can be harmful. Special sensors can also be integrated to ensure everything works seamlessly during operation of the curved conveyor. Such sensors help to monitor if there are any blocks or issues on the conveyor belt. If something blocks their path, the sensors notify workers immediately. This also addresses any problems quickly and prevents possible accidents from happening to ensure that everyone is safe.

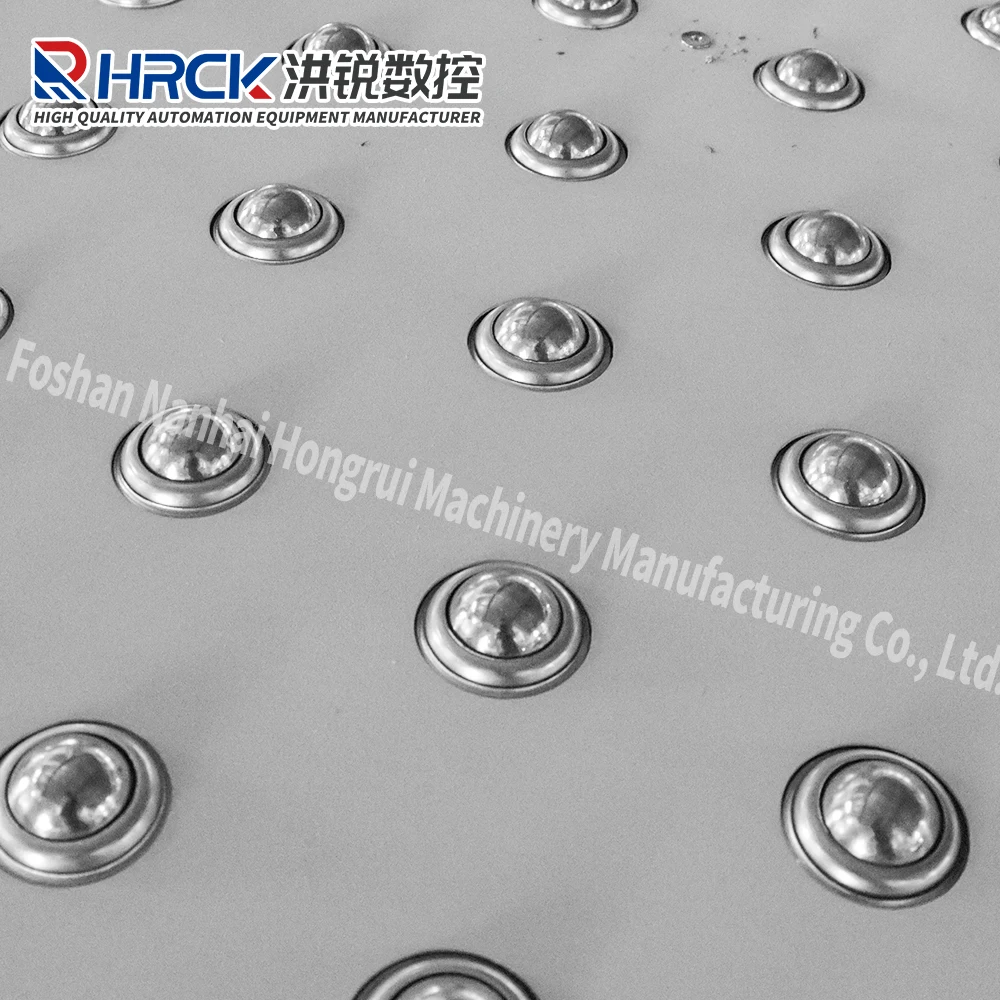

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of manufacturing automation technology. With over a decade's experience, we have a specialization in developing, manufacturing, and constructing a broad range of automation solutions, including conveyor belts as well as roller lines and gantry feeders. Our products are constantly improved and we launch new products every year to keep up with the ever-changing needs of the market. Our commitment to quality is reflected in our curved conveyor, TUV, SGS, and ISO certifications, ensuring the highest standards of quality and performance. You will benefit from our top-of-the-line technology and products that maximize efficiency and high-quality.

We offer a variety of after-sales support that include installation, commissioning and maintenance. Our curved conveyor is highly trained and responds quickly to any issues that might occur. With a global network of support We provide prompt technical assistance and solutions no matter where you are. We're dedicated to providing professional and efficient support that guarantees the stability of your equipment. This will enhance the efficiency of production and improve customer satisfaction. Our services are designed to meeting your needs. We are determined to meet or exceed expectations.

At curved conveyor we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.

Our research development team consisting of over 10 highly skilled engineers is committed to developing innovative products that meet market needs With continuous technological research enhancements to products provide customized solutions that are tailored to the specific needs of clients specifications Our robust RD capabilities don't just improve technology but also keep leading position in the marketplace deliver reliable efficient automation solutions breaking the limits of traditional technology cutting-edge technological trends This ensures curved conveyor of every product develop