Hello everyone! So in this article, we will discuss the drum roll conveyor from HRCK. This machine is special because it helps a lot in factories to move the materials fast and hassle free. Well, then are you ready to learn about drum conveyors and why they are such a unique product? Are you ready to begin this amazing discovery tour!

It was extremely challenging to move heavy things in a factory before drum conveyors were invented. Now think about pushing carts, driving forklifts or even lifting by handmouseleave the hard work to an heiress and have someone else (In Misss video) take care of our heaviest tasks. The work was slow and at times dangerous, with workers readily susceptible to harm. The drum conveyor needed that as well to get it all started. Drum Conveyor: A large machine with rotating barrels. Aggregate and Liquid Transport Barrels is a system that takes up to dozens of materials moving very fast in an easy way by barrels. And for a lot of factories, this was some revolutionary shit and made them work faster safer and better than ever before. It frees workers up to focus on more important jobs besides fighting with large items.

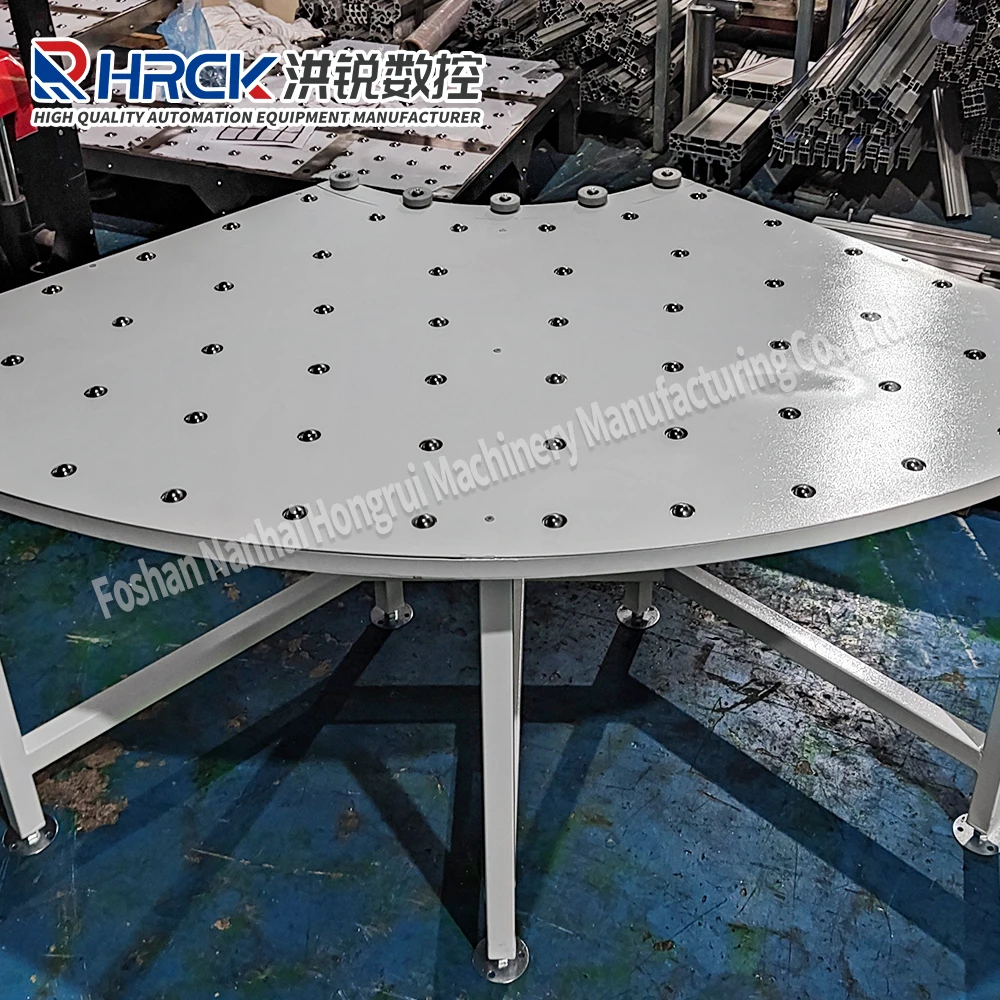

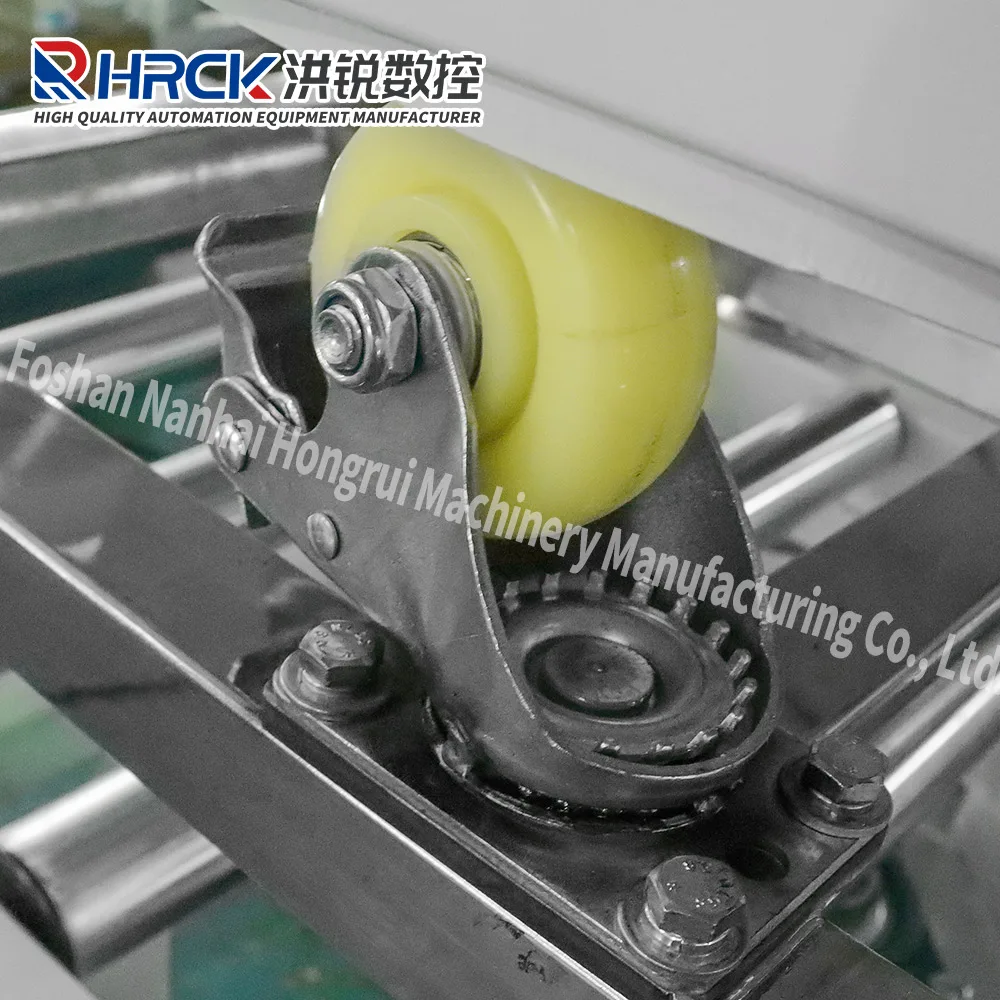

A wooden drums automatic line contains rotating barrels and takes materials from one place to another. A motor – to give the barrels some oomph! The materials are poured onto the barrels and carried with them as the hoops rotate. It is a pleasant merry-go-round for the materials! It has revolutionised the way factories transport goods, and for good reason. A drum conveyor makes it fast and easy to move heavy parts, large items righting actions tape imageand other materials. It makes the entire process simpler and allows to make everything easy in a factory.

Drum conveyors are considered to be better than other types of transmissions, for a number of different reasons. Drum conveyors, for example, have a high transport speed. This makes factories to work faster and manufacture more products in less time. Think of how much more a factory makes when everything takes place at the speed limit (faster)! Drum Conveyors are usually more robust and be able to carry heavier loads without breaking. Therefore they can be worked on without needing repairs all the time. In summary, less energy is used to convey materials with a drum conveyor. This is a plus for these units, since factories save in electricity.

The drum conveyors are cost-effective machines manufactured for the businesses. They are able to move heavy products fast, with much less expense in power as well as needing the least variety of employees. This can save companies money in terms of labor and energy costs for faster ROI. When a company saves money, it can produce new projects or help their workers. Similarly, the design of drum conveyors is such that maintenance and repairs are easily effected with minimal downtime. You never will be able to heal a roadway and fill it in properly if something go wrong. In conclusion, drum conveyors are an intelligent and cost-effective option for businesses seeking to move materials quickly.

Drum conveyors are deployed in a myriad of industries including manufacturing, automobile and even airplanes. In the manufacturing, they are also used to facilitate exposure with heavy going on a diet along an assembly line. That enables factories to produce things more quickly. Drum conveyors are quite common in the car industry; if you know that scene from Ed 1, those are drum-conveyed cars traveling between two points of a factory to help get everything assembled. Drum conveyors play a role in the airplane industry carrying large parts between factory zones so they can be put together correctly. Drum conveyors are designed with flexibility in mind, meaning they can be used for a wide variety of jobs and products!

Over 10 engineers work together to create innovative products that are in drum conveyor market Through continuous technological research enhancements to products offer customized solutions tailored to specific client specifications Our robust RD capabilities don't just improve technology but also keep edge in the field With cutting-edge technology breaking traditional boundaries offer efficient reliable automation solutions ensuring optimal performance for every product create

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the drum conveyor of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

Our extensive after-sales assistance includes installation, commissioning, and maintenance. Our customer service staff is highly educated and is drum conveyor to respond to any problems that may occur. With our global support network We provide prompt technical support and solutions no matter where you are. We're committed to providing professional and efficient service that ensures long-term reliability of your equipment. This will enhance efficiency in production and ensure satisfaction for customers. We take your requirements into consideration and aim to meet your expectations with each service we offer.

We drum conveyor developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.