If you have ever used edge banding strips, chances are that it was almost impossible for you to transfer them from one location to the next without dropping or spilling. If you have, then fear not; many other people have too! Unfortunately, this is a struggle most humans endure. Now, do not worry as we have got your back with our HRCK edge banding return conveyor.

Moving the edge banding stripes from one place to other is super easy with conveyor belt for edge bander. Rather than carrying each strip individually (which can become tiresome and time consuming), our conveyor carries large amounts of strips in one job. This will not only save your time but also saves you energy. Since the strips need to be transported in this way with much less effort, you can focus on your own work and do more than in a shorter period.

Our conveyor is not only used to carry the edge banding strips, but it will help deliver a much more productive work. With our edge banding return system, you will have no material wasted. It all means that you can be a lot more effective and similarly, smash out extra work inside the same quantity of time.

Using edge banding strips is a quick and easy way to give your projects that product style finish, but one of the abouts most people worry about with this material (well at least I do) is wasting it. The last thing you want when the strips fall or go missing, as they are one time use once gone. This wasted material can really add up in a hurry and cost you money. Well not anymore, with our HRCK edge banding return conveyor you will never waste material again.

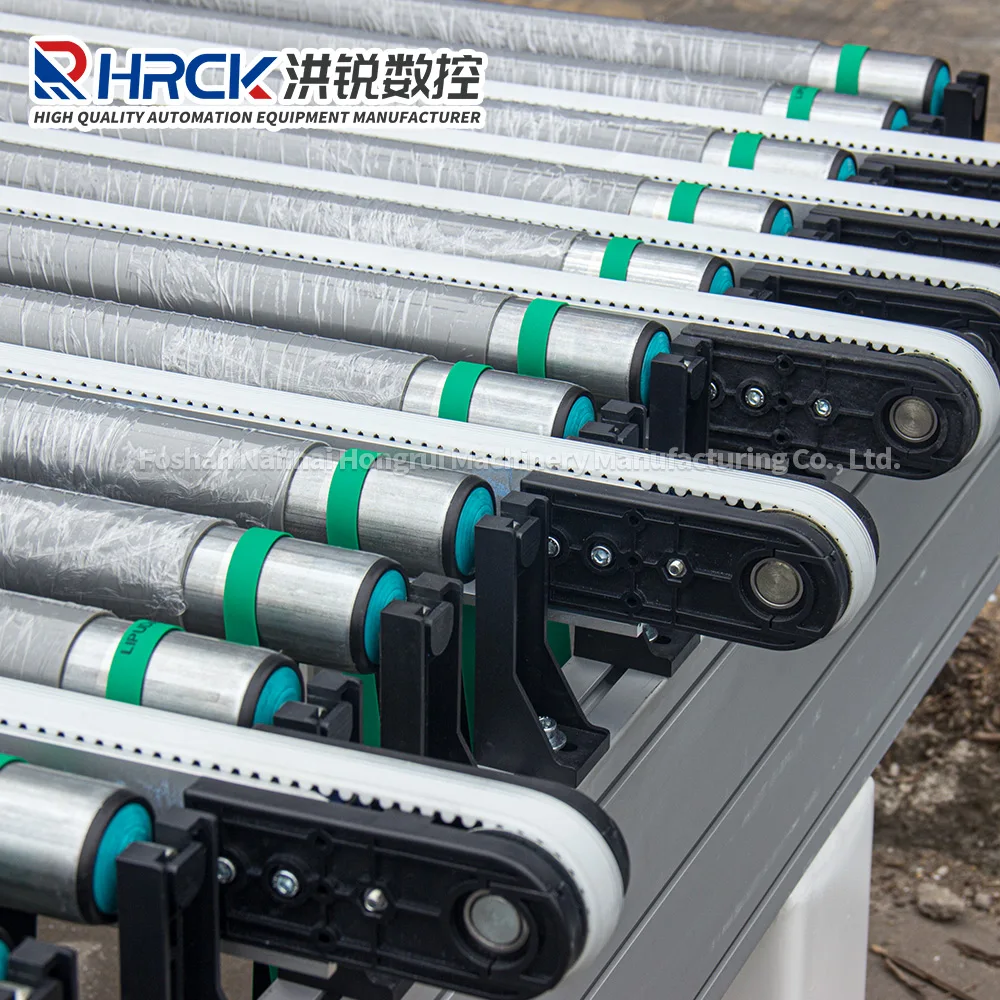

The conveyor that we use is designed to return all of these edge banding strips back into the storage area, even if they come off their own trays during transit. That simply implies there are no duds, and every single strip gets efficiently used up- which equates to some cost savings in the long run. When you start using our dependable edge banding conveyor, watch how much less material waste.

Our conveyor system also ensures that your workshop remains clean and orderly irrespective of the size edge banding strip. Our edge banding machine conveyor prevents tripping over loose strips and maintains a workable area, not to mention future time spent as strip after strip has accumulated on the floor.

In summary, the overall benefits of our HRCK edge banding return conveyor are a time-tested and trustworthy answer to some typical problems you may face regarding the feeding cycle in terms of with strip edges. Not only does our conveyor system help you with achieving maximum production rates and reducing your downtime by working faster for you, but it also helps in getting things done quicker overall.

The extensive after-sales services we offer include installation as well asEdge banding return conveyor and maintenance. Our skilled service team is quick to resolve any issues that arise while operating. We have a global support network, which allows us to offer timely solutions and technical assistance regardless of where you happen to be. Our commitment to speedy and efficient service guarantees the long-term, reliable operation of your equipment, improving the effectiveness of your production and ensuring that you are satisfied with our services. We take your requirements into consideration and strive to exceed expectations with every service that we provide.

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable Edge banding return conveyor ensuring the highest performance for each product design

We have built up a significant amount of expertise in the field of woodworking at Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since the beginning we've specialized in offering customized automation solutions, tailored to the specific requirements of woodworking, ranging from conveyor systems to processing equipment. Our team has an in-depth understanding of the unique challenges and requirements of production woodworking. Based on years of Edge banding return conveyor experience, we design and provide effective, reliable automation systems that increase efficiency in production as well as product quality. We don't just assist clients to optimize production processes, however, we also help them address specific industry issues. Each system is perfectly tuned to the woodworking needs. We can provide you with expert support in the woodworking industry, giving your production line an edge.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the Edge banding return conveyor of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.