If you’re getting a new piece of furniture and want it to look awesome, you need to learn about something called edgebanding. Edgebanding, which is a special process where there is an addition of a material to the edges of wooden furniture. This can smooth those edges and leave the furniture with a finished appearance. In rare cases, the edgebanding may ""pop off"" the piece. This is referred to as an edgebander return conveyor. In this article, we discuss, what an edgebander return is, its pros and cons, troubleshooting common problems, and how to optimize the whole process to save material and money.

What we mean with edgebanding is that we apply a special glue to attach the edgebanding material directly to the edge of each piece of furniture. This as it helps to make the furniture look good. Word of advice: The glue doesn't always work as intended, and the edgebanding is known to fall off. Edgebander return is what this situation is. Edge banding is made from a variety of materials such as wood, PVC, and ABS plastics. That kind of glue is designed to adhere well to those materials — a major consideration in keeping the furniture looking good.

Well, Let’s focus on the pros and cons of gantry crane. The most important benefit of edgebanding is that it makes the furniture look very nice. The edges of the furniture are pretty rough and not great when they are not edgebanded. But in the case of edgebanding, the edges are flush and clean, so the piece just looks way nicer as a whole. To the proudest of people, who want their furniture to look its best, this can be very important.

Solving the common problems of edgebander return The first points are that the glue to stick it does not sticks very much. There are several reasons why this could happen, such as if the furniture is not prepared, if you apply the glue incorrectly, or if you do not let the glue dry as necessary. In order to avoid this issue, one has to ensure furniture is prepared for edgebanding correctly and glue is applied properly.

A very common problem is that the edgebanding material starts coming off after some time. Instead, the glue can dry out, exposing the fixtures to heat and moisture or if the glue was applied incorrectly in the beginning. This kind of damage is something that you will have to deal with, so you must take care of the furniture properly, and ensure your edgebanding is done correctly and with the appropriate materials.

Proper steps are critical to getting the edgebander return performed optimally. In addition, proper preparation of the furniture, correct application of the glue and edgebanding material, and cure and dry time of the glue are all included. This means that you also have to use the right tools for the type of edgebanding you are dealing with. This makes sure the edgebanding is tight and in good condition for long time.

Finding ways to save money and materials are also critical in edgebander return. In order to do this, you must utilize the proper materials and methods. Selecting the appropriate edgebanding material based on the furniture you are working with, best-suited glue to use, and ensuring that your furniture is appropriately prepped for the edgebanding process. Making sure that edgebanding is done correctly the first time is also fundamental to the process. That saves you from having to redo it later, which can waste further materials and labor.

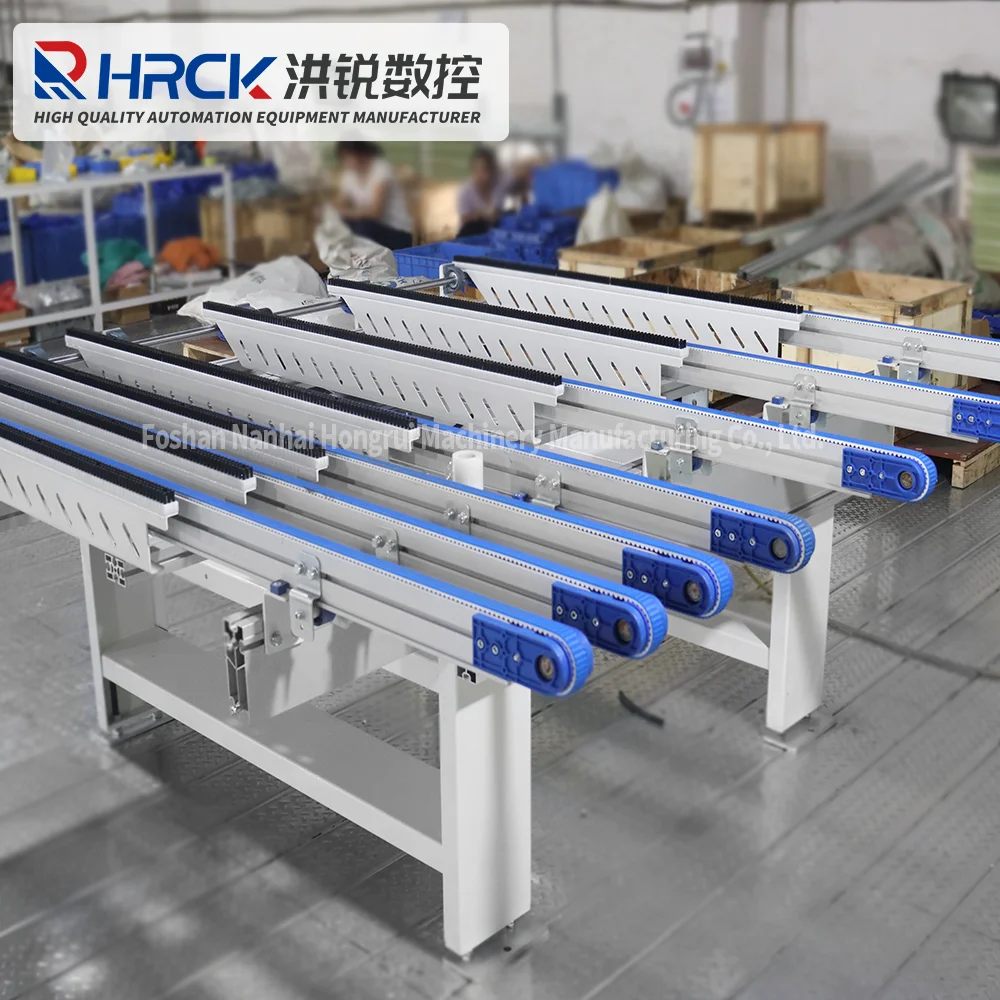

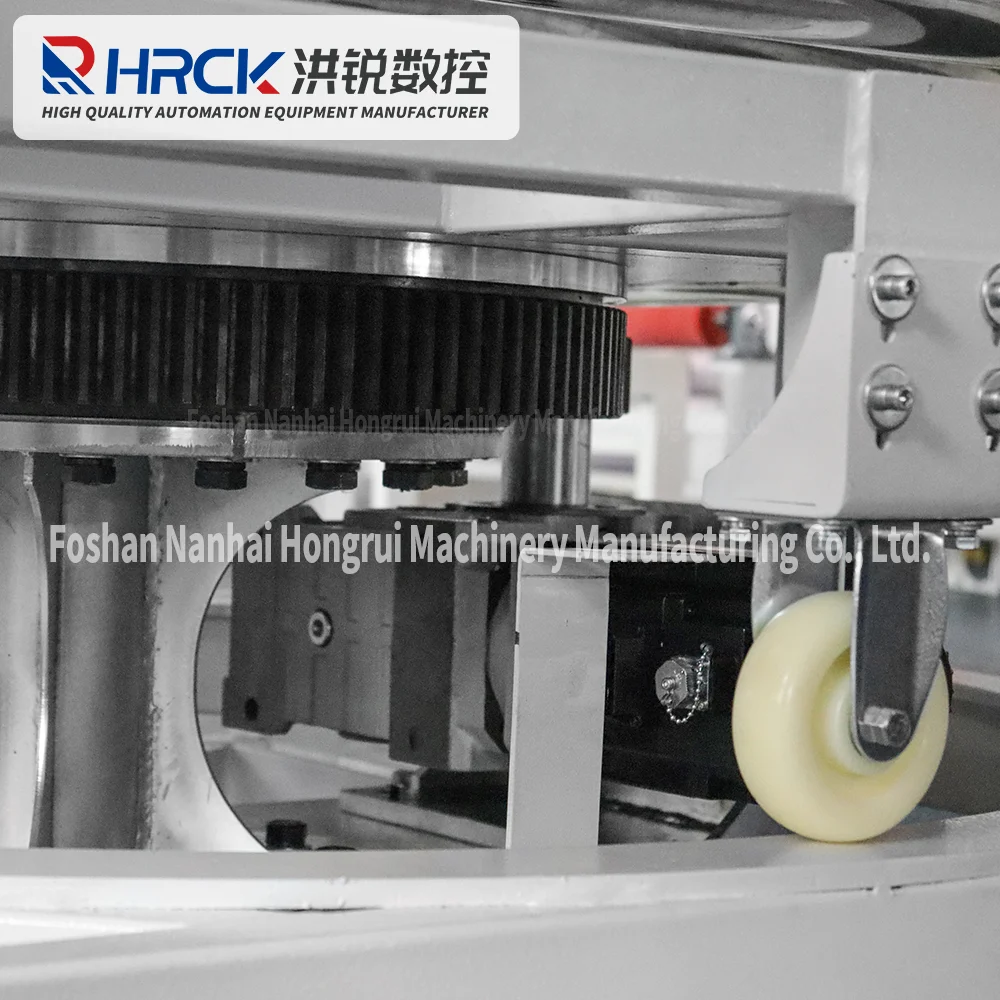

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront in factory automation technology for over a decade. We have over 10 years of experience in designing, manufacturing and installing automation solutions, such as belt conveyors and roller lines. We constantly improve our products and introduce innovative solutions annually to meet evolving market demands. Our ISO, TUV and SGS certificates reflect our dedication to quality, and guarantee the highest standards in reliability and performance. When you work with us, it is possible to get top-quality technological support and equipment designed to edgebander return effectiveness and quality.

Over 10 engineers work together to create innovative products that are in edgebander return market Through continuous technological research enhancements to products offer customized solutions tailored to specific client specifications Our robust RD capabilities don't just improve technology but also keep edge in the field With cutting-edge technology breaking traditional boundaries offer efficient reliable automation solutions ensuring optimal performance for every product create

Our extensive after-sales assistance includes installation commissioning and maintenance Our expert service team is quick to resolve any issues that arise during the course of operation With a edgebander return network we offer timely tech support and solutions no wherever you are Our dedication to dependable and prompt service guarantees long-term and stable operation of your equipment This will increase production effectiveness and customer satisfaction Our services are focused on satisfying your requirements We aim to exceed your expectations

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed significant expertise in the woodworking industry. We've been providing custom automation solutions to woodworking businesses since the day we started. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is familiar with the demands and difficulties of production woodworking. We create and implement efficient and robust automation systems that enhance production efficiency and the quality of products. Our specialized knowledge will not only help our clients improve their processes for production, but also tackles the technical challenges specific to their industry, ensuring that each system perfectly aligns with the needs of woodworking. We can provide you with professional assistance in the woodworking sector, giving your production line an edgebander return in the market.