There are several steps to take in order to create a nice wood door. They first select the right materials. They source their top-quality wood at HRCK from all over the world, including Africa, Finland, and Russia. They choose the best wood since it is durable and beautiful. The HRCK professionals understand that to create door that be strong, long-lasting, and contribute to your home, good quality materials have to be used.

Next, the wood is cut and shaped into the appropriate design. This is where the fun begins! Craftsmen — skilled workers with decades of experience — use time-honored techniques as well as state-of-the-art equipment to ensure that every door is crafted with care. The craftsmen have been trained for years and this aids in making beautiful and intricate doors.

HRCK that's why they uses many special machines called CNC machines to make the details on the doors. These are actually pretty cool robots that cut the wood to specific shapes so you could create a fancy design. This technology enables HRCK to form beautiful designs that elevate their doors. The result, the touch of a skillful human, and the accuracy of a machine, produces doors that are both functional and exquisite.

Being precise is a key element to making wooden doors. Everything has to be perfect, from the size of the door to its design. If the measurements are incorrect, the door could not be installed properly. HRCK has knowledgeable employees who dedicate time and effort into making each door just right. They know how every little thing can change the outcome.

HRCK also ensures every door is of high quality by checking them individually. They have a special team that checks every door to make sure it fits HRCK’s high standards. Their commitment to precision and production excellence does set their wood doors apart from the competition. It is proof that HRCK truly cares what they produce and wishes to deliver their customers the finest.

At HRCK, the first step of the production process is selecting the right materials. From there, the wood is cut and shaped appropriately. This is a crucial step as the shape of the door must correspond with the client's preferences. Skilled workers handcraft the doors using old-school techniques, adding special designs and details that are the hallmark of each individual door.

The very first things done to the door parts whenever they are made is to check them. The door is inspected thoroughly, checking every component to ensure it meets HRCK’s high standards. They want to make sure that the doors are sturdy, attractive, and functional. Once approved, the doors will be coated to protect them and ensure a long life. Not only does this exterior coating help protect the doors from scratches and the elements, but it also adds a little shine!

We provide foreign wood doors production line after-sales services such as installation, commissioning and maintenance. Our skilled service team responds quickly to any issues that arise while operating. We have a global support network that enables us to offer timely solutions and technical support, regardless of where you might be. Our dedication to dependable and efficient service guarantees the long-term stability and reliability of your equipment, improving productivity and customer satisfaction. We are attentive to your needs and strive to exceed expectations with every service we provide.

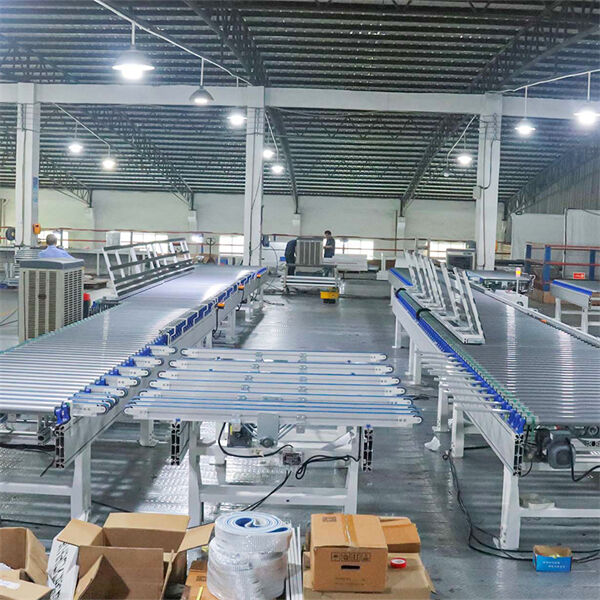

We have built up a significant amount of expertise in the field of woodworking at Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since the beginning we've specialized in offering customized automation solutions, tailored to the specific requirements of woodworking, ranging from conveyor systems to processing equipment. Our team has an in-depth understanding of the unique challenges and requirements of production woodworking. Based on years of foreign wood doors production line experience, we design and provide effective, reliable automation systems that increase efficiency in production as well as product quality. We don't just assist clients to optimize production processes, however, we also help them address specific industry issues. Each system is perfectly tuned to the woodworking needs. We can provide you with expert support in the woodworking industry, giving your production line an edge.

foreign wood doors production line 10 engineers collaborate to create products that align market requirements With continuous technological research product enhancements provide customized solutions tailored to specific client requirements Our strong RD capabilities not only advance technology but also keep leading position in the marketplace offer reliable efficient automation solutions breaking the boundaries of traditional technology cutting-edge technological trends This guarantees optimal performance for each product develop

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of technological advancements in the field of factory automation. We have more than foreign wood doors production line of expertise developing, manufacturing and installing automation solutions, such as belt conveyors and roller lines. Our products are continually upgraded and we launch new products every year to keep up with the ever-changing needs of the market. Our ISO, TUV and SGS certifications show our commitment to quality, and guarantee the highest standards in reliability and performance. When you choose us, you benefit from top-notch technological support and products designed to maximize efficiency and quality.