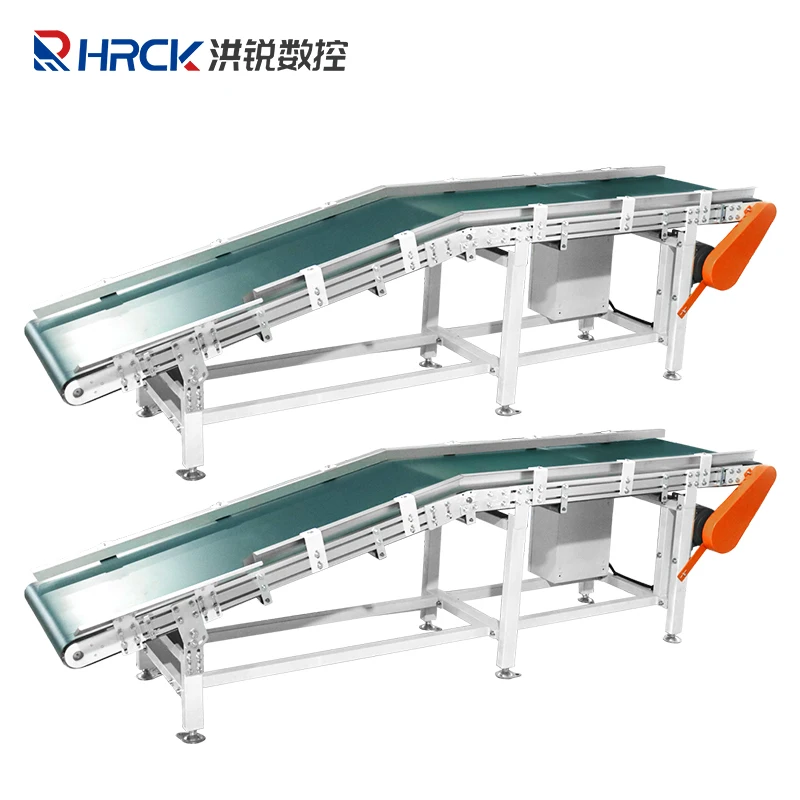

It works the same fashion as mobile cranes and jibes but have you ever wondered how they are even being moved inside large warehouses? Well, this is an interesting question. As such, why not share some breaking news of me own Gravity Roller Conveyor — To move things across the floor faster and easier Gravity roller conveyor. This HRCK gravity conveyer is a very revolutionary machine, it also takes the weight out of workers and moves them from one side to another. So that begs the basic question: How does a gravity roller conveyor work? It uses gravity to help items go from one end of the conveyor all-theway throught it. Gravity wants to work this way for you too — as long as the something getting set down (up) on that belt does so gently, then fine: it all rolls smoothly enough. The warehouse workers can carry heavy things hassle-free, without even breaking a sweat putting them on the ground in an easy manner. It is basically a slide for giant shit

Gravity roller conveyors are also perfect for assembly work because while it is great at moving heavy objects, it can be made to stop and hold things in place. More like a worker piecing together something, such as in building toy or furniture. During the movement of conveyor, you may add other parts into it such that distinct belt sections which will continue to move consecutively. It is said that the parts assembling process using it faster as workers can easily and quickly complete their task. Instead of having to run all over the place trying to hunt down an undercover, they could just pick one off-conveyor belt yourself

Space is key in a warehouse. If there is no room, then it may well be a bit constraining. On the other hand, a gravity roller conveyor is space-saving as it does not need any storage. You may well to place this in a handy order of warehouse layout and so that it is easy enough the things on any end are needed, leaving you with space for other stuff. The HRCK gravity conveyor enables workers to travel through the warehouse more easily and reduces instances in which you might trip over something or other employees.

A lot of weight can be hauled at a good cost even when it comes to other types of machines or equipment. Gravity roller conveyor from HRCK may be even cheaper. The conveyor is only a one-time purchase (and it should last you many years). This renders it suitable for businessmen looking to save money in the long run. Plus, by the nature of a conveyor being low maintenance it means that running costs are also minimal. This gives businesses the chance to utilise their money in other areas, investing it as opposed to repairing.

The practicality of a gravity roller conveyor is that it should glide along easy, not get stuck and otherwise calls for little attention to maintain the components. That is why workers can avoid the problem-solving process if they keep moving material all of the time. Gravity all the way on this conveyor so there are no motors or electric do-dads to check every week. This HRCK conveyor belt for edge bander lets the workers get their work done with no interruptions.

We provide a wide range of after-sales services that include installation commissioning as well as maintenance Our service staff is experienced and responds swiftly to address any issues that may arise during operation With a global support network We provide Gravity roller conveyor support and solutions no wherever you are We're committed to providing efficient and professional support that guarantees the reliability of your equipment This will enhance production efficiency and customer satisfaction We are attentive to your needs and work to exceed your expectations with every service that we provide

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable Gravity roller conveyor ensuring the highest performance for each product design

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the Gravity roller conveyor of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

At Gravity roller conveyor we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.