Have you ever taken a wooden table or a house and then seen it and wondered where does the wood comes from? Lumber mills are special places that way, and they help transform wood from giant forests into lumber that arrives at our homes.

HRCK has a killer process for turning wood into wood; trees into products. It starts in a forest with sturdy, tall trees. Workers select trees carefully to fell. They use special tools so that they do not hurt and harm the forest.

When a tree is cut down, it rides on a giant truck to the sawmill. The sawmill is a sort of magical place where trees become wood. The first stage is the removing of the rough bark from the trunk. This is called debarking. The bark is stripped away so the wood will be clean and smooth.

Then, the trees are sliced into long boards by big saws. These saws are highly precise — they cut wood exactly how workers desire. Well, some boards are wide, and some are narrow. Some are long, and some are short. The boards are all unique and will share various utilizations.

The boards are then sent to a special machine (a planer) that cuts them down to size. The big tool is a planer and makes the wood nice and smooth. It smooths out any rough patches or bumps. Workers examine each board carefully to ensure that it is perfect.

There are real people toiling away in the lumber mill. They assist in loading trees, observing the machines and ensuring everything goes as planned. HRCK cares about its employees and believes they should feel safe and comfortable during their working hours.

Not only they make wood, but care for the world as well! They dry wood not with harmful chemicals, but by heat treatment. This is called kiln drying. They also reuse sawdust, sending it toward uses like animal bedding or fuel.

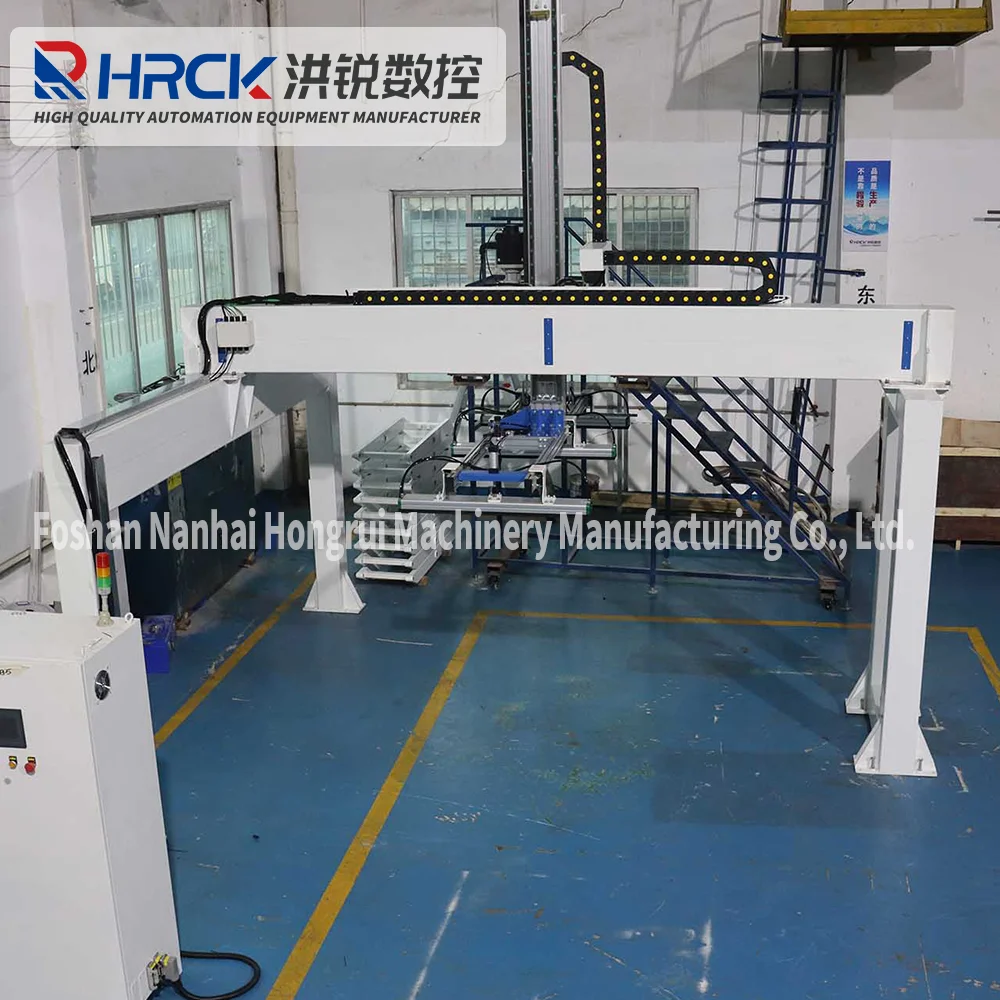

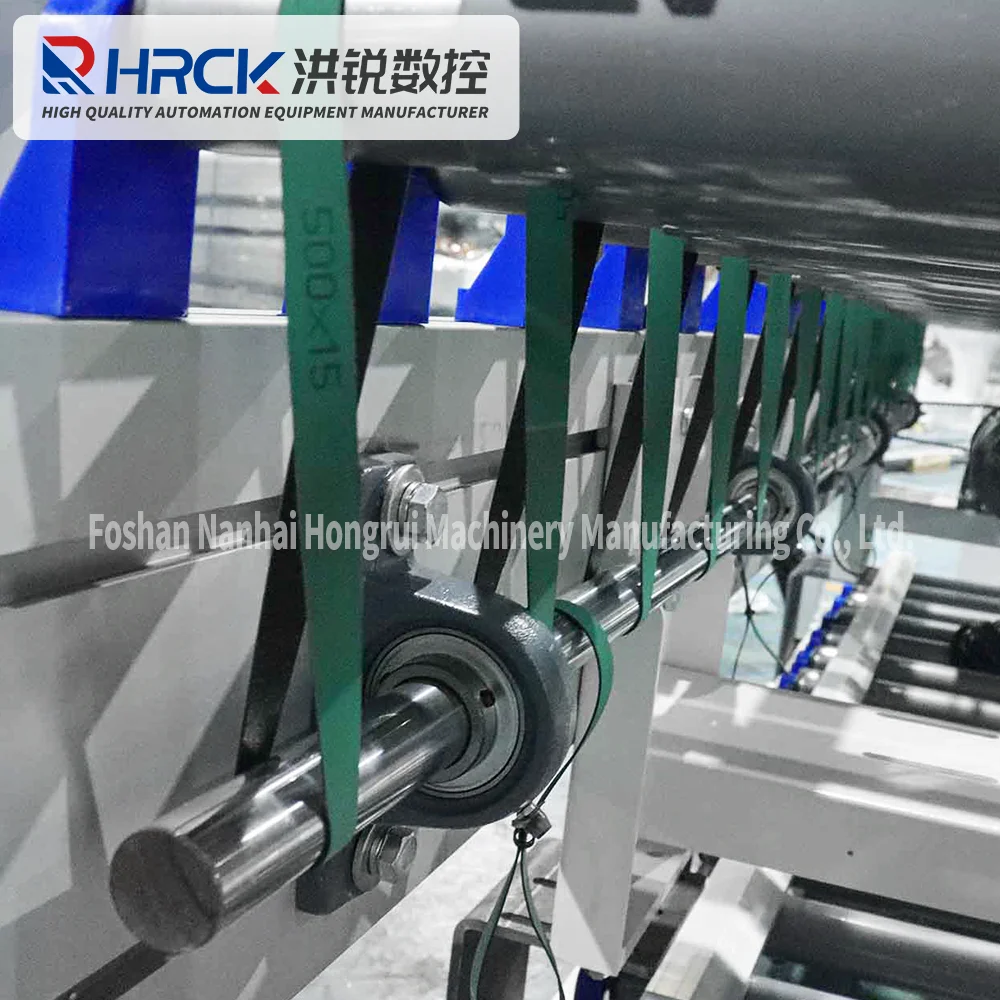

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of factory automation technology for over 10 years. With more than a decade's expertise, we specialize in the design, manufacture, and putting in place a variety of automation solutions, such as belt conveyors, roller lines, and gantry feeders. We constantly improve our products and introduce innovative solutions annually in order to meet changing market needs. Our ISO, lumber production line and SGS certifications demonstrate our commitment to quality, which ensures the highest standards in the reliability and performance. Our customers will benefit from top-notch technology and products that improve efficiency and quality.

We lumber production line developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable lumber production line ensuring the highest performance for each product design

lumber production line extensive after-sales services we offer include installation of the system, commissioning it and maintaining. Our expert service team responds promptly to any issues that may arise while operating. With a global support network We provide prompt tech support and solutions no regardless of where you're located. We're dedicated to providing professional and efficient service that will ensure the long-term reliability of your equipment. This will increase production efficiency and customer satisfaction. Our services are designed to meeting your needs. We strive to surpass expectations.