Machine conveyors are essential tools used in several different businesses and modern industry. They aid in transporting different types of materials from one point to another, thus facilitating work. In other words, a conveyor can carry raw materials to their needed locations in a factory, and then later, finished products to the shipping area. The working principle of conveyer is that they work 24 hr round says one of the major reasons behind the importance if machine conveyors. This 24/7 enabling helps the businesses to maintain their tasks without wasting to much time.

How Machine Conveyors Work{“type”:”block”,”srcClientId”:”e303e6c9-f40c-4455-bf69-154042b8ca61″,”srcRootClientId”:”c337cb00-f93f-4767-82c6-d80a108b6abd”}

Machine conveyors can only function properly and efficiently when they have been constructed correctly and are adequately serviced. This involves ensuring that the belts or chains that assist in moving the materials are not overly slack and are also not overly tight. If they are too tight, the materials can break. If they are tight, this can lead to the broken conveyor. The rollers and bearings, which are components that allows the conveyor to operate seamlessly, need to be added oil on regular basis. It improves their functioning and also longevity. The sensors and controls that manage the conveyors also need to be properly configured so they can identify problems and ensure everything runs as it should. Businesses should also have a contingency plan if the conveyor system malfunctions.

The beauty of the machine conveyors is that they can operate in continuous movements and do not have to take breaks. That means they can run automatically, so workers don’t have to constantly watch over them. As the conveyor is traversed and started, it can work independently. This way, if a product is not ready on time, the rest of the equipment in the automatic factory will continue working, as the manufacturing plants are not going to be shut down. (Really useful, during a busy time when plenty of work to do.

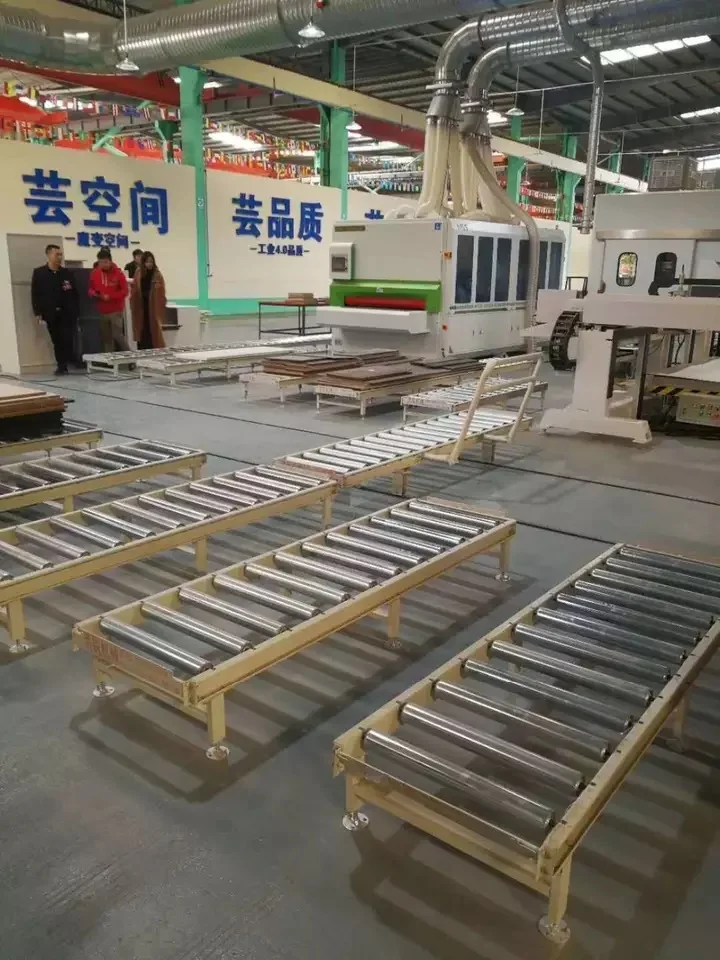

There are many other types of business enterprise that use machine conveyors including bedroom, packaging, device assembly, food and beverage, and also baggage handling in an airport. They assist in the movement of materials of various shapes and sizes, including raw materials and finished products ready for retail. Without machine conveyors, moving the large quantities of materials needed around a factory or warehouse would take much longer and be much more labor intensive. This might delay production and make fulfilling customers’ orders more difficult.” Machine conveyors are essential for keeping the economy moving forward because they help businesses to manage their facilities in the best way possible.

Machine conveyors are designed to work day in and day out for years to come. They are strong enough to hold heavy things, so they can hold a lot of materials without getting damaged. They're also meant for use in extreme environments, like heat or cold, making them really good for — Use Cases, as the techies call it. Plus, they require less maintenance than most machines. This also makes them a clever option for businesses that require moving materials properly and effortlessly without the worry of consistent injuries.

HRCK: Ensuring optimum machine conveyor performance, every day This is precisely why we offer premium quality machine conveyor systems that fulfil the requirements of various industries. Examples of what we offer with our globossa systems include: They’re also meant to be user- and maintenance-friendly. HRCK machine conveyors will know no use problems which bring your business to an halt.

machine conveyor running extensive after-sales services we offer include installation of the system, commissioning it and maintaining. Our expert service team responds promptly to any issues that may arise while operating. With a global support network We provide prompt tech support and solutions no regardless of where you're located. We're dedicated to providing professional and efficient service that will ensure the long-term reliability of your equipment. This will increase production efficiency and customer satisfaction. Our services are designed to meeting your needs. We strive to surpass expectations.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the machine conveyor running of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

More 10 engineers collaborate to machine conveyor running innovative products that are in line market requirements offer tailored solutions to meet client dem s through continual product improvement research into technology maintain a competitive edge robust RD capabilities offer reliable efficient automation solutions that push the limits of traditional technology advancing technological trends This ensures the highest performance for each product design develop

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed a vast expertise in the woodworking sector. Since our inception we've focused on delivering customized automation solutions tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well-versed in the challenges and requirements of production in woodworking. machine conveyor running years of experience in the field we develop and offer effective, reliable automation systems that increase efficiency in production as well as product quality. We not only help clients improve production processes, but also solve industry-specific challenges. Each system is aligned with woodworking requirements. Our woodworking experts can give your production line an edge with our expert support.