The machines are surrounding us and so do the factories. They manufacture so much of what we use on the daily in almost all sectors from our clothes to phones and even cars. Have you ever wondered, how are any of these things created? The combined two lines are used by some plants to function faster but effectively. Or, assembly lines as they are often called. The HRCK panel furniture production line There are several type of production line. This episode I take you through HRCK's Panel production line and how it functions to provide us with quick, precise and what we actually need. Everywhere production lines are changing the way factories work And that is by allowing workers and machines to make multiple items at once instead of making only one item. This process is called mass production. However yes again that would be much more time-consuming if one were to actually start making things by hand. But better mass production is possible. For example, some factories may use different production lines to make specific parts of a product that can save time and energy. Now this is where the panel production lines come in! They help in increasing the production process by providing ease of manufacturing.

HRCK Panel Production Line is a processing line for the panels which belong to rare kinds of lines. Panels are an integral part of many objects that we use in everyday life such as the panels used for cars, refrigerators and electronics. HRCK are also able to manufacture these panels very quickly, with great precision using a panel production line. The line features a variety of machines to crank out each panel. This machine is just for cutting, that one can only give the shape of panel and these are to join them in a pleasurable way. They create 'big jigsaw puzzle' and keep asking you to form it with each machine (enemies) playing their role, where every now or then a job comes from no-where.

With the panel production line a HRCK can keep track of what people want and need. The fact is that modern factories need to maintain orders full because most people are used buying products and they want them now. HRCK panel furniture product line does not construct just one panel from start to finish, it builds many panels simultaneously based on the same factory and production line. Moreover, it results less errors while processing as most of the labour is done by machines. The better tested and reliable these parts can be when used in other products, the more likely that HRCK will consistently output quality panels.

Panel production line Dimension: 6m X 3.7M Feature Support Latest and Best technology HRCK panel which produce with high quality and special in Indonesia. With its. Another important connection that line is the computer running everything. The computer orders the machines what to do, and how. The panels are also visually inspected for production errors as well. The computer catches the faults and makes a correction before one can truly ruin an entire panel. As a result, HRCK can ensure that they make perfect panels every time — which is why their high-quality standard remains unchanged.

Panel production lines are necessary for the factories to meet this new level need, as in current era of increased demand products. The lines needs to run for the faster production of item, in this case those who openly demand fast production on their products. This HRCK mdf panel production line automates a warm way toward guaranteeing high caliber in each board created. Pioneer production lines help businesses produce parts more quickly so that people can have those products faster, and with the assurance of quality.

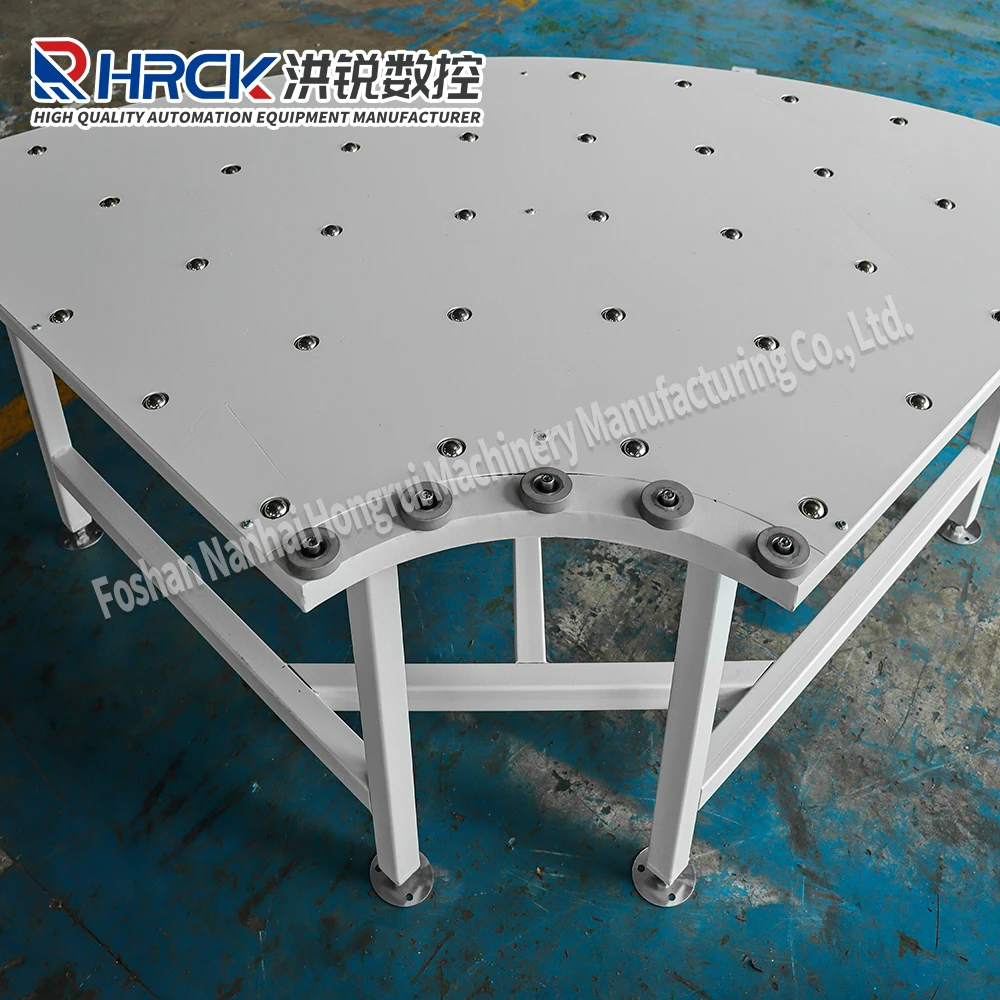

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed a vast expertise in the woodworking sector. Since our inception we've focused on delivering customized automation solutions tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well-versed in the challenges and requirements of production in woodworking. Panel production line years of experience in the field we develop and offer effective, reliable automation systems that increase efficiency in production as well as product quality. We not only help clients improve production processes, but also solve industry-specific challenges. Each system is aligned with woodworking requirements. Our woodworking experts can give your production line an edge with our expert support.

We provide a wide range of after-sales services that include installation commissioning as well as maintenance Our service staff is experienced and responds swiftly to address any issues that may arise during operation With a global support network We provide Panel production line support and solutions no wherever you are We're committed to providing efficient and professional support that guarantees the reliability of your equipment This will enhance production efficiency and customer satisfaction We are attentive to your needs and work to exceed your expectations with every service that we provide

Over 10 engineers work together to create innovative products that are in Panel production line market Through continuous technological research enhancements to products offer customized solutions tailored to specific client specifications Our robust RD capabilities don't just improve technology but also keep edge in the field With cutting-edge technology breaking traditional boundaries offer efficient reliable automation solutions ensuring optimal performance for every product create

Panel production line has been at the forefront of manufacturing automation for more than 10 years. We have over 10 years of expertise developing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are constantly refined and come up with new ideas every year to meet the ever-changing needs of our customers. Our commitment to quality is evident in our ISO, TUV, SGS, and ISO certifications. They guarantee the highest standards of quality and performance. When you work with us, it is possible to get top-quality technological support and products specifically designed to enhance efficiency and quality.