Do you ever wonder how the very things we work with each day are engineered? If it is the clothes we wear, or the toys a child plays with — everything boils down to being just made in a factory before getting to us. Factories are also bustling structures, filled with hundreds of workers doing the things which make some product or another. Moving materials just one component of a factory grip on the manufacture landscape And here is the role of gantry cranes.

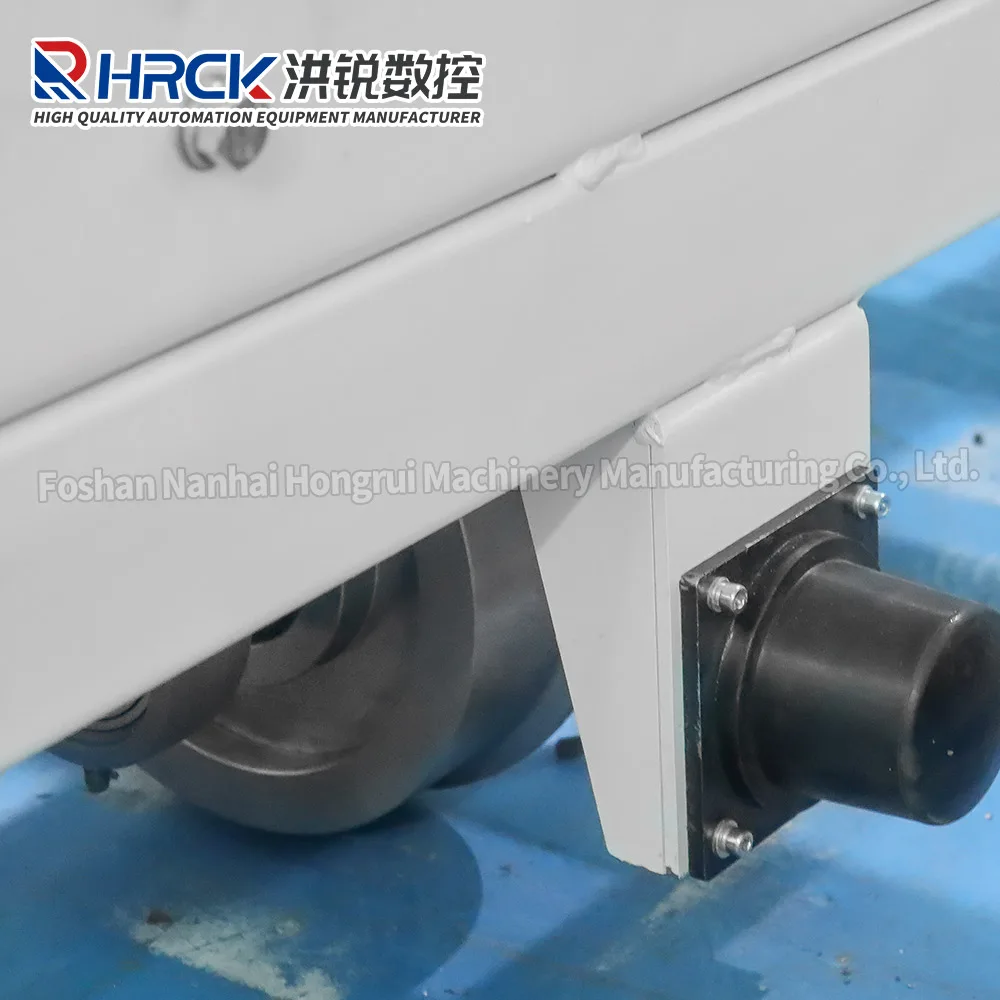

We, at HRCK manufacture something known as powerised roller conveyors which are special purpose machines that helps the factories to move their things easily and very fast. Powerised roller conveyor — This type of system is propelled by electricity or other source where rollers are placed on track.pyplotter These are the rollers that drive items on the conveyor. Point industrial companies bring boxes as well as other materials on the actual conveyor, which can after that carry these carrying them instead of doing it personally. This allows workers to be focused on their tasks and not having to stop what they are doing in order move items by hand.

If faster materials flow through, the whole factory can operate both quicker and more efficiently. As a result, we can produce more products and ship them to stores much faster. Use of a vacuum wood stacker system—this will help in ensuring that materials are always moving along the line. In a production process workers simply do not have to stop and take boxes or other materials away, we solved that part. This means they can focus on the work and produce more items.

Do check out HRCK, we are the manufacturing house for different series of powerised roller conveyor systems specific to a factory! A few of our systems are intended for hire materials travel from one end in the factory to some other, basically within a straight line. Some others are designed in such a way that it can move the materials up or down level wise, across different levels of factory. Want a powerised roller conveyor system that is tailored to your needs or factory?

Powerised roller conveyors have another standout quality; they can be self-propelled. This allows the conveyor to carry materials on its own, without workers needing to push it. This saves a lot of time and simplifies the entire factory process, then because it makes more efficient. When workers don't have to move items manually, they are free to do more important work.

You will get a number of benefit in your factory after using powerised roller conveyor. It can save money and work as a boost your productivity. Good material flow means employees spend more time making parts and less pickand place work to move materials. In other words, the more products a factory is able to produce in less time allows it for better gains and bigger successes.

The use of a powerised roller conveyor will save time and can cut costs, because it requires less physical energy labor. Workers will be able to move them by way of hands by then a system which moves materials automatically using the conveyer is not.Hence workers need less effort and time for moving. It helps to defer tiredness reducing the possibility of injuries, which in turn saves money for the factory.

At powerised roller conveyor we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.

Our powerised roller conveyor after-sales support includes installation, commissioning and maintenance. Our expert service team responds promptly to any issues that may arise in the course of operating. We offer a worldwide support network that allows us to provide prompt solutions and technical support, no matter where you may be. Our commitment to prompt and professional service ensures the long-term, stable operation of your equipment, improving efficiency and satisfaction of customers. Our services are geared towards fulfilling your requirements. We are determined to meet or exceed expectations.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront in factory automation technology for over a decade. We have over 10 years of experience in designing, manufacturing and installing automation solutions, such as belt conveyors and roller lines. We constantly improve our products and introduce innovative solutions annually to meet evolving market demands. Our ISO, TUV and SGS certificates reflect our dedication to quality, and guarantee the highest standards in reliability and performance. When you work with us, it is possible to get top-quality technological support and equipment designed to powerised roller conveyor effectiveness and quality.

Over 10 engineers work together to create innovative products that align to market dem offer customized solutions to meet specific needs through continuous product improvements research into technology keep edge extensive RD capabilities deliver reliable efficient automation solutions breaking the boundaries of conventional technology leading technological trends This ensures the highest performance of every product powerised roller conveyor