The HRCK gantry crane is used to transfer logs from the forest to the sawmill or wood processing factory and can be of great help. The conveyor belt in this machine is of high capacity to move maximum logs. The logs are moved off the belt quickly and safely as well which is critical. As a result loggers are able to transport timber without having to hoist and carry heavy logs manually. This helps in saving on their time and effort, hence a cost saver as well.

So while a timber conveyor is very useful, it has its many drawbacks and other methods should be considered beforehand. For starters, it is far quicker than hauling wood by the armload or other equipment. Faster logs = more timber per unit of time. In other words, they are able to work more and thus earn a higher income.

Secondly, it is user friendly with the HRCK vacuum wood stacker system. This makes the area less dangerous for workers transporting logs. Now, the workers no longer have to lift and push extremely heavy logs. That is crucial as it reduces the risk of accidents to a great extent. Sawmill or wood processing plant work is dangerous and operating with safer machines helps protect everyone.

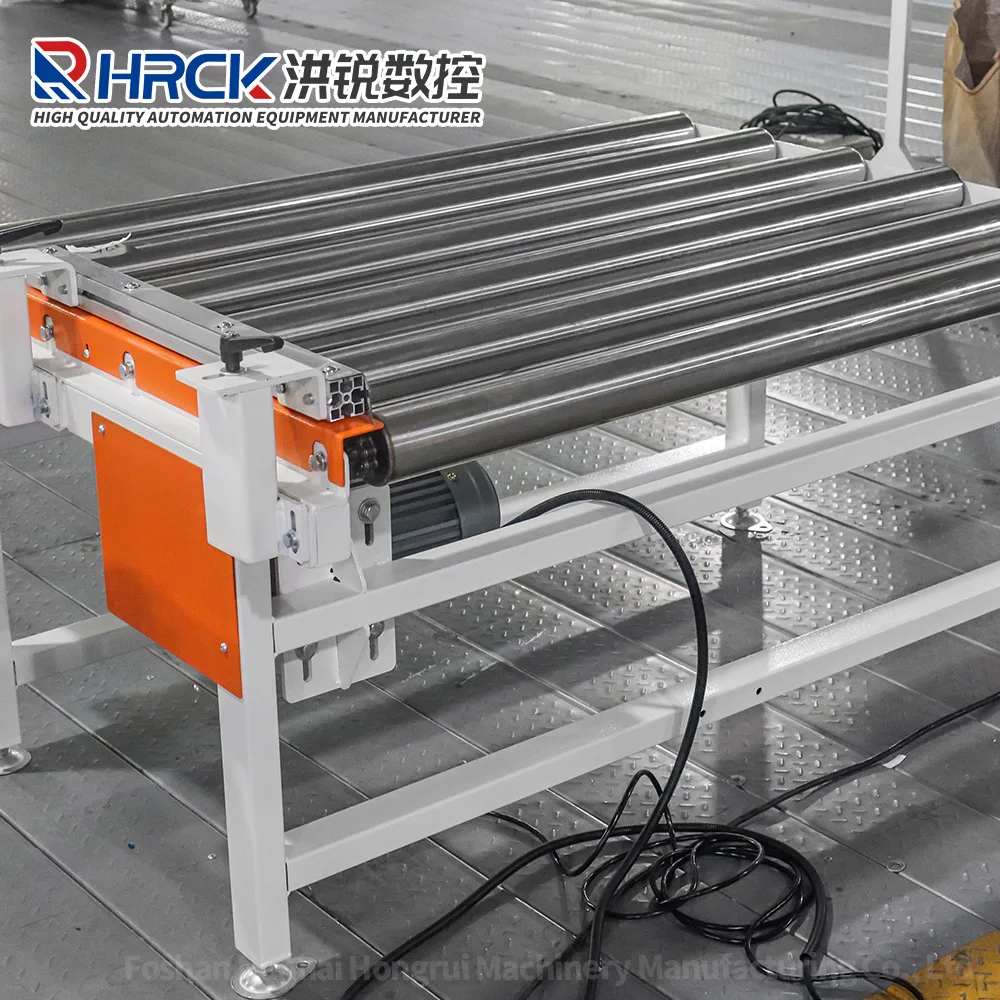

Even more idealistic is shrinkable wood conveyors, affordable criminged timber managing and this all are of course automated which a lot more offers quick wooden refinement. Such systems are intelligently designed to transport wood within the plant. Since, their design can be customized to meet the different requirements at each sawmill and wood processing plant.

HRCK automatic conveyor systems for timber are also famously sophisticated. The sensors detect the logs as they are transported on a belt. This technology in turn adjusts the speed of the conveyor based on how many logs are being carried and what size they are. It allows everything to function in a fare type of way without getting jammed. It can even categorize the logs by their size, shape, and type in automatic! This effectively reduces the amount of physical labour that workers need to perform and thereby makes their jobs less arduous.

Timber Conveyor Systems — Custom For Maximum Production This, of course, enables sawmills to process even more timber in a smaller period. Each sawmill or wood processing plant can be adapted to match the individual requirements by using it HRCK conveyor system. And this adaptability means no waste during the production process which is great for when you need to get as much work completed as time allows.

To get things tones right, the timber conveyor you choose thus plays a huge role in ensuring that your sawmill operations are successful. Sawmills vary,by size, capacity, or its particular tasks.. further study may be necessary§saws saw--the based on which type of conveyor you are interested in buying. The HRCK timber conveyor is a modular solution, meaning it can reconfigured to suit any individual sawmill requirements.

Over 10 engineers work together to create innovative products that align to market dem offer customized solutions to meet specific needs through continuous product improvements research into technology keep edge extensive RD capabilities deliver reliable efficient automation solutions breaking the boundaries of conventional technology leading technological trends This ensures the highest performance of every product timber conveyor

At timber conveyor we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.

timber conveyor has been at the forefront of manufacturing automation for more than 10 years. We have over 10 years of expertise developing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are constantly refined and come up with new ideas every year to meet the ever-changing needs of our customers. Our commitment to quality is evident in our ISO, TUV, SGS, and ISO certifications. They guarantee the highest standards of quality and performance. When you work with us, it is possible to get top-quality technological support and products specifically designed to enhance efficiency and quality.

We provide extensive after-sales services which include timber conveyor, commissioning, as well as maintenance. Our team of service technicians is highly educated and is quick to respond to any problems that may arise. We offer a worldwide support network that allows us to offer timely solutions and technical assistance, no matter where you may be. We're committed to providing efficient and professional service that ensures long-term stability of your equipment. This will improve productivity and satisfaction of customers. We are attentive to your needs and work to exceed your expectations with each service we provide.