Wheel production line is a combination of many machines used to make wheels. This system is designed specifically for the production of vehicle wheels, including cars, bikes, and other vehicles. It all starts with raw materials — basic materials like steel or aluminum. These raw materials are then processed in various stages until they turn into finished wheels ready for application.

Making a wheel starts with the raw materials we just discussed. First, these materials are melted in a very hot furnace. Next, the molten matter is poured into a mold, which shapes it into a wheel. Once the mold has been filled, it is left to cool. After its cooled, any excess not part of the wheel is cut away. This is an important step because it allows for good foundational work on the wheel.

After the wheel is roughed into shape, it passes through a series of machines that smooth it into a respectable finish. These machines perform critical functions that include buffing the surface to a luster, spraying it with bright paint and adding textures that can aid in grip or visual appeal. All of these steps are critical to ensuring you have a high-quality wheel.

The wheel doesn’t go directly to the store when it’s fully done. They first need to be inspected to ensure with quality standards. This inspection process is critical since it guarantees best possible wheels get shipped out for mounting on vehicles. Once the wheel passes this quality inspection, it is packed and shipped to go on to a car or a bike.

To operate the machines properly, a lot of machines are required to produce tires, where workers will stand and rotate the machines and actually put tires in factories. These workers are trained to know how each machine operates and monitor everything. They keep a close eye on the machines and tweak as necessary, so that everything runs like a well-oiled machine. This method aides in removing the mistakes or issues that might arise when creating a product.

One tool we get to use is known as computer-aided design CAD. It enables our engineering team to virtualize designs and perform analyses of wheels in the computer before they’re physically produced, for example. This saves us time and money, since we now have a chance to identify and correct any issues at the design stage itself, before even starting wheel manufacture. This ensures that everything is perfect before commencing the production.

We use another key technology, which is robotics. For example, robots are trained to perform specific roles on the production line, like painting and polishing wheels. Not only does this speed up the production line, but it can also helpensuring the performance characteristics of the end product. They work tirelessly without a loss of performance, which produces better and more consistent outcomes.

Our extensive after-sales assistance includes installation of the system commissioning it and maintaining Our expert service team is quick to resolve any issues that may wheel drive production line while operating With a global network of support and a rapid response time to tech support and solutions no matter where you are We are committed to providing professional and efficient service that will ensure the long-term reliability of your equipment This improves efficiency in production and ensure satisfaction for customers We are attentive to your needs and work to exceed your expectations with every service that we offer

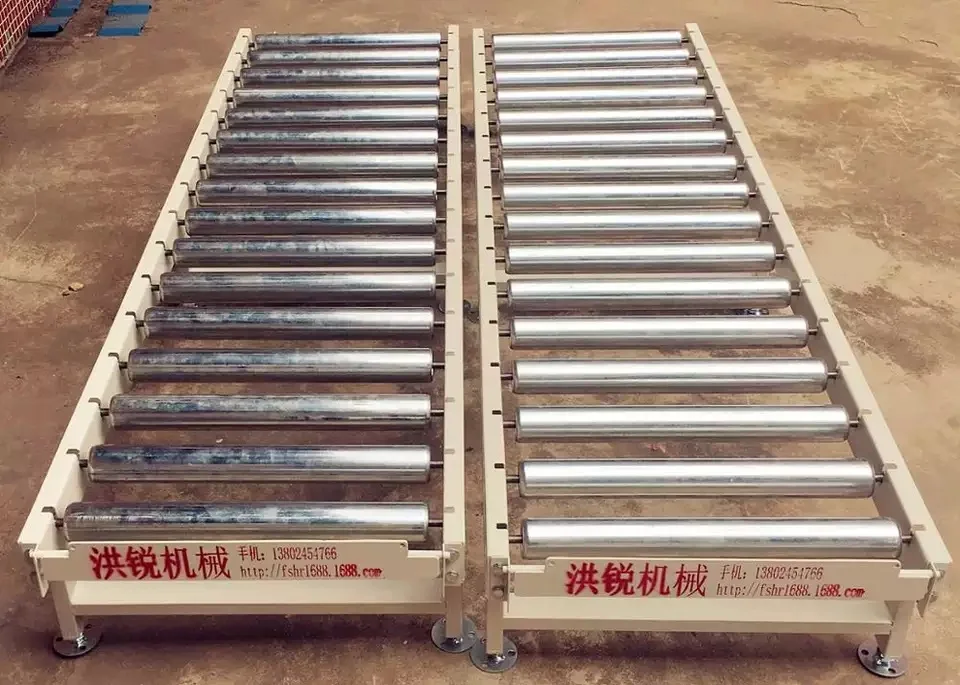

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of factory automation technology for over 10 years. With more than a decade's expertise, we specialize in the design, manufacture, and putting in place a variety of automation solutions, such as belt conveyors, roller lines, and gantry feeders. We constantly improve our products and introduce innovative solutions annually in order to meet changing market needs. Our ISO, wheel drive production line and SGS certifications demonstrate our commitment to quality, which ensures the highest standards in the reliability and performance. Our customers will benefit from top-notch technology and products that improve efficiency and quality.

Over 10 engineers work together to create innovative products that align to market dem offer customized solutions to meet specific needs through continuous product improvements research into technology keep edge extensive RD capabilities deliver reliable efficient automation solutions breaking the boundaries of conventional technology leading technological trends This ensures the highest performance of every product wheel drive production line

We wheel drive production line developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.