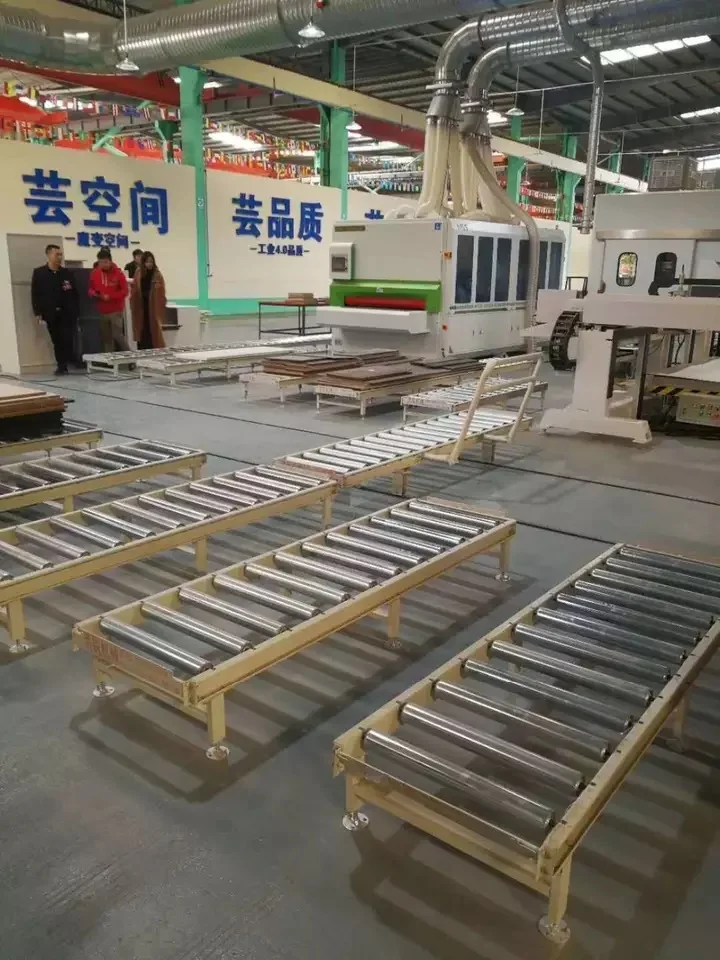

These wooden pallets are clear to moving aspects from one spot to another. Pallets are flat platforms that can be used to hold large items, boxes and shipping containers. They facilitate transportation of these products globally. Pallets also keep everything safe while in transit, reduce shipping costs and allow for faster, efficient loading and unloading. HRCK wooden doors production line in use: But how is a wooden pallet made?

The boards then enter a stringer machine. This machine cuts and notches the boards to interlock as required by the design of the pallet. The notches enable the boards to interlock and cross each other into a firm, rectangular shape. Finally, after everything has been cut and notched, the pallets are either nailed or stapled together. Once this is all done, the final pallets can be shipped out where they're needed.

ProWaveHRCK is one of the factories that widely applies high-tech in its wooden pallets production line to improve the process. These machines allow for extremely accurate measuring, cutting and notching of the wood. They include an automated stringer machine that recognizes the correct lengths of wood for every pallet. It also generates less waste because the machine will only cut what is necessary for each unique pallet design.

Higher efficiency is crucial as it saves time and resources. HRCK also tailors the pallets to different customers depending on their requirements. That means if a customer needs a pallet with a different dimension or configuration, HRCK will produce it for them. The automated stapling system is another significant element of this process. This system prevents penetration of the nail into the base and prevents each nail from passing at the precise depth and angle, further keeping the stability of pallets.

In addition, HRCK includes recycled wood in its pallets. Doing so reduces waste and conserves natural resources. As a result, the production process is also crafted in a way to ensure minimal water and energy use, safeguarding our planet in the process. HRCK has added solar panels to reduce its carbon footprint. With the company burning less fossil fuels due to the power of this clean energy, it can establish a greener practice than the alternative.

PalletsHRCK builds pallets to last. It is of very strong and high-quality timber that can withstand heavy loads. This allows these pallets to bear heavy products without shattering or crumbling. Pallets undergo extensive testing to make sure they are safe. They are examined to ensure that they have compliance with the relevant critical standards, such as those defined by the International Standards for Phytosanitary Measures. Such requirements are intended to minimize the international movement of wood packaging material, and to prevent the spread of harmful pests and diseases that can be associated with wood packaging materials.

Likewise the automotive industry in its use of heavy duty pallets to transport parts and engines. As the wooden pallet industry continues to develop, there are also some environmental issues that need addressing. HRCK takes on serious issues in topics like deforestation and waste. This is a transportation-app provider that is committed to responsible and sustainable practices that don't only consider the needs of customers but also to the environment.

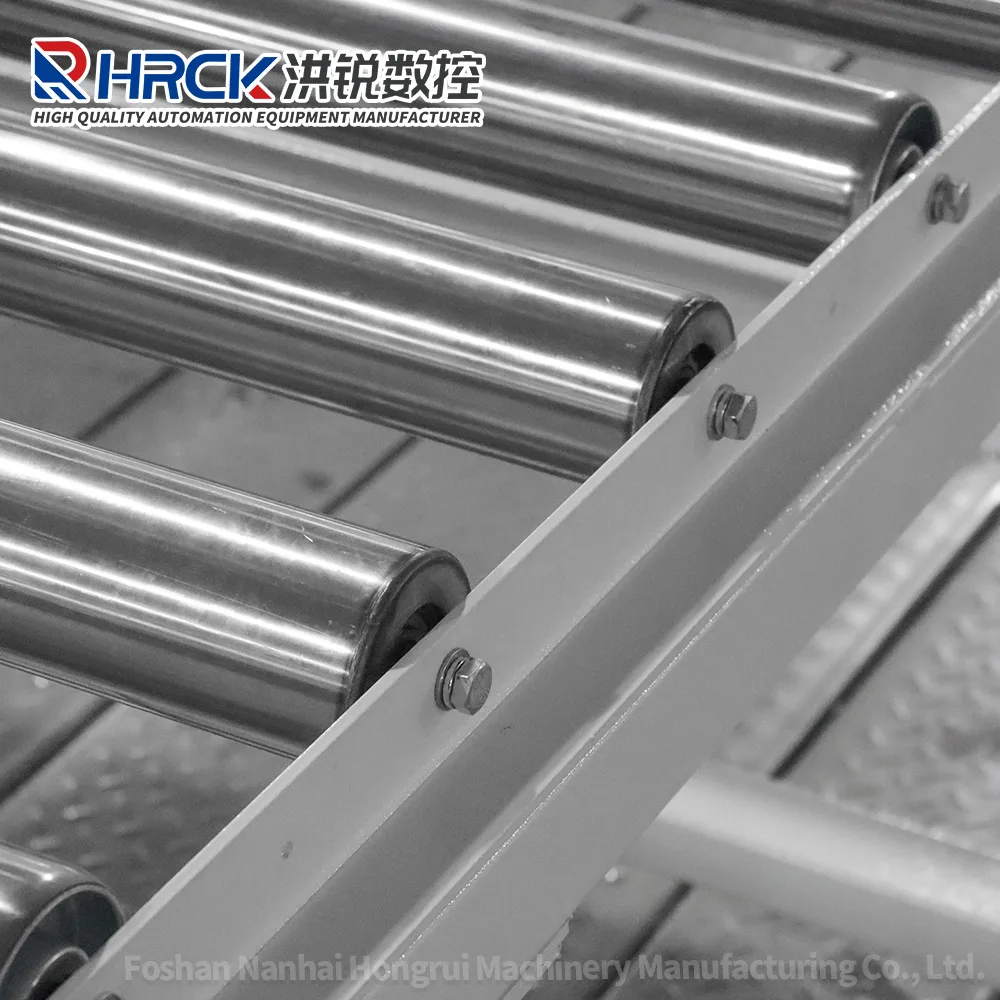

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is a leader in manufacturing automation technology. We have over 10 years of expertise designing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are continually upgraded and we introduce new solutions each year to keep pace with the changing market needs. Our ISO, TUV and SGS certificates reflect our dedication to quality, which ensures the highest standards of reliability and wooden pallet production line. We offer high-end products and technology that optimize efficiency and quality.

We provide extensive after-sales services which include wooden pallet production line, commissioning, as well as maintenance. Our team of service technicians is highly educated and is quick to respond to any problems that may arise. We offer a worldwide support network that allows us to offer timely solutions and technical assistance, no matter where you may be. We're committed to providing efficient and professional service that ensures long-term stability of your equipment. This will improve productivity and satisfaction of customers. We are attentive to your needs and work to exceed your expectations with each service we provide.

wooden pallet production line 10 engineers collaborate to create products that align market requirements With continuous technological research product enhancements provide customized solutions tailored to specific client requirements Our strong RD capabilities not only advance technology but also keep leading position in the marketplace offer reliable efficient automation solutions breaking the boundaries of traditional technology cutting-edge technological trends This guarantees optimal performance for each product develop

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed significant expertise in the woodworking industry. We've been providing custom automation solutions to woodworking businesses since the day we started. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is familiar with the demands and difficulties of production woodworking. We create and implement efficient and robust automation systems that enhance production efficiency and the quality of products. Our specialized knowledge will not only help our clients improve their processes for production, but also tackles the technical challenges specific to their industry, ensuring that each system perfectly aligns with the needs of woodworking. We can provide you with professional assistance in the woodworking sector, giving your production line an wooden pallet production line in the market.