HRCK is committed to providing excellent woodworking products and services to our customers. We have a woodworking factory which is a very special part of our business. This factory is crucial due to its advanced machines that manufacture fine woodworking products rapidly and precisely. We are proud of what we do, we want to share with the world how special our factory is.

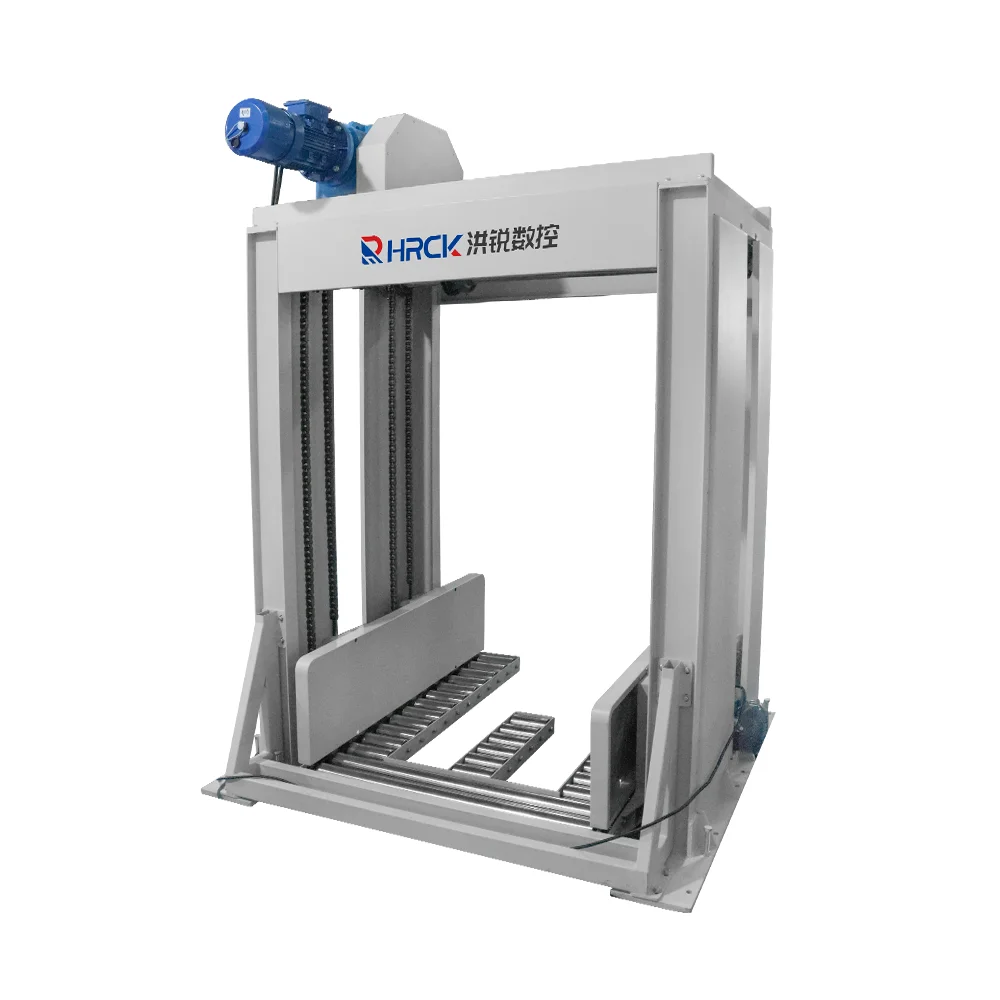

We have a very special woodworking factory which is mostly run by machines. These machines allow us to build awesome products with almost no human assistance. Even with our own machinery and carpentry, we have contemporary tools that clean, smooth and assemble things like a timber-cutter, sander and only fit better to realise tasks. It allows us to build products quickly and correctly. Each of our machines has its own role to play in our team like factory.

We utilize modern machines and equipment in our factory to ensure the quality of our products and services to our customers. The machine is used for Many Important Jobs. For instance, there are machines that sand wood, some that cut wood, some that drill holes, and others that give the wood a nice finished surface. These all machines cooperate with each other in a team play to ensure that each product is prepared perfectly for our customers.

Our factory is filled with numerous amazing machines that are working to produce top quality woodworking products. Everything is controlled on the factory floor by one main computer. This intelligent computer examines the functioning of the machines and corrects them every so often to ensure the correct manufacturing of everything. It ensures it all stays the same way as when you started.

It all starts with a massive heap of timber. This wood is put into a machine that cuts it into the appropriate shape and size. After it’s cut, the wood is passed through a series of machines that sand it smooth, drill holes, and treat it to a beautiful finish. Last but not least, the wood is assembled and packed up – ready to go to customers awaiting their new products.

Our factory consists of various machines working in co-operation with each other to produce our products. The first machine in the process which cuts the wood into the shapes and sizes we need. Then the wood passes through a sanding machine, which smooths out rough patches and leaves the wood pleasant to the touch and ready for use. The following machine bores holes and other features into the wood, a critical step to creating details.

At the end of this process, the wood is completed with paint, lacquer, or stain depending on which— What the customer likes far the best. This last addition gives the wood a rich finish, and prepares it for its new home.

We provide a wide range of after-sales services that include installation commissioning as well as maintenance Our service staff is experienced and responds swiftly to address any issues that may arise during operation With a global support network We provide woodworking automatic line factory support and solutions no wherever you are We're committed to providing efficient and professional support that guarantees the reliability of your equipment This will enhance production efficiency and customer satisfaction We are attentive to your needs and work to exceed your expectations with every service that we provide

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable woodworking automatic line factory ensuring the highest performance for each product design

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of technological advancements in the field of factory automation. We have more than woodworking automatic line factory of expertise developing, manufacturing and installing automation solutions, such as belt conveyors and roller lines. Our products are continually upgraded and we launch new products every year to keep up with the ever-changing needs of the market. Our ISO, TUV and SGS certifications show our commitment to quality, and guarantee the highest standards in reliability and performance. When you choose us, you benefit from top-notch technological support and products designed to maximize efficiency and quality.

We have woodworking automatic line factory up a significant amount of experience in the woodworking industry within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of satisfying their specific needs. Our team is familiar with the demands and challenges of production woodworking. With years of experience in the industry, we design and provide efficient, reliable automation solutions which improve efficiency of production and product quality. Our specialized knowledge assists clients in optimizing their processes, but also tackles many technical issues that are specific to industry making sure that each system is perfectly aligned with the needs of woodworking. Our woodworking specialists can help your production line gain an edge through our professional assistance.