XPS board foam is a special fluffy kind of board. And it is designed to insulate buildings and homes to keep them warm in winter and cool in summer. That means energy savings and comfort for people. We have devised a smart and safe method to manufacture XPS foam board at HRCK quickly. We want to make good boards that fit our customers.

We produce XPS foam boards using the best machines available at HRCK. These machines are highly engineered which assists us in producing a large number of foam boards in a short period of time. From our side with our technology, energy saving goes inside and our machines work like a clock. This allows us to create additional boards with less resource waste. We can make the durable and strong foamed boards utilizing the most advanced mechanisms.

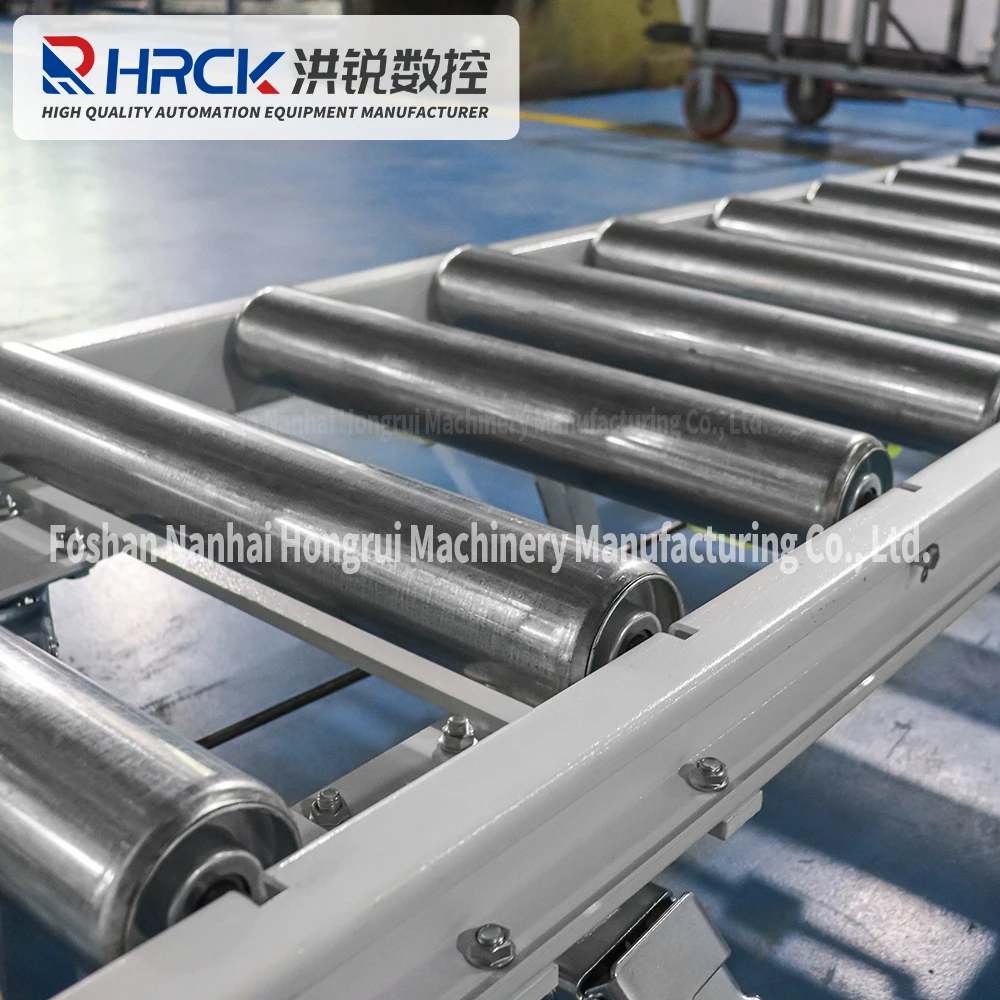

Our assembly line was built to be exceptionally fast. This allows us to complete foam boards in time for our customers, which is essential [to them] as well as to us. Automation+ provides us a smart system to manage and monitor the entire production process. This ensures that all foam boards produced under one system are of same quality. Our conveyor belts move the boards smoothly, and our cutting tools are extremely exact. This allows us to manufacture foam boards that are tailor-suited to particular demands and needs of our clients.

At HRCK our primary product is high quality XPS foam boards. We talk very carefully about how we construct each of our boards to be just the right size and thickness. This meticulous process ensures gently insulating foam boards which are highly effective but also safe to handle for our customers. Our goal is to ensure the highest of standards for every board we produce so that our customers will have confidence in the product they receive.

Our machines are designed to manage high volume production. That is, they can produce a number of foam boards without any complaints. That's why we only use high-quality materials to build our machines, making them work well and last long. Our home machinery doesn't have to be repaired all too often and we have a schedule to ensure everything functions properly. Our consistent performance and quality ensure that our clients can always depend on us for top-notch foam boards, whenever they place an order.

Our extensive after-sales assistance includes installation commissioning and maintenance Our expert service team is quick to resolve any issues that arise during the course of operation With a xps foam board production line network we offer timely tech support and solutions no wherever you are Our dedication to dependable and prompt service guarantees long-term and stable operation of your equipment This will increase production effectiveness and customer satisfaction Our services are focused on satisfying your requirements We aim to exceed your expectations

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of factory xps foam board production line technology for over 10 years. With more than a decade of expertise, we specialize in creating, manufacturing and constructing a broad range of automation options, including belt conveyors as well as roller lines and gantry feeders. Our products are continuously improved and we come up with new solutions every year to keep up with changing demands of the market. Our ISO, TUV and SGS certificates reflect our dedication to quality and ensures the highest standards of quality and reliability. You will benefit from our top-notch technology and products which maximize efficiency and quality.

At xps foam board production line we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.

Over 10 engineers work together to create products that comply market requirements can tailor solutions to meet client dem s through continual product improvement as as technological research Our xps foam board production line RD capabilities not only improve product technology but also maintain leading position in the field provide reliable effective automation solutions that push the boundaries of conventional technology cutting-edge technological trends This ensures optimal performance for every product develop