قريباً: روبوتات شبيهة بثلاجات قديمة في الحركة! هذه الروبوتات تعمل على حمل الصناديق والمواد ذهابًا وإيابًا. وتُعرف باسم الحزام النقل الآلي عربة نقل ذاتية القيادة، أو AGV اختصارًا! هذه العربات مشابهة للسيارات ذاتية القيادة الصغيرة التي تقوم برفع وتسليم الأشياء دون أن يوجّهها سائق بشري. أين تُستخدم؟ تُستخدم في العديد من الأماكن بما في ذلك المستودعات والمصانع والمستشفيات ومراكز التوزيع، لذا أصبحت جزءًا أساسيًا من كيفية نقل السلع في عالمنا.

يمكن أن تبدو وحدات النقل الآلية (AGVs) بطرق مختلفة تمامًا. بعضها صغير ويمكنه نقل صندوق واحد فقط في المرة الواحدة، بينما البعض الآخر أكبر بكثير ويحمل العديد من الصناديق أو حتى رفوف المنتجات. تحتوي على أجهزة استشعار وكاميرات خاصة تمكنها من رؤية ما حولها. أثناء تحركها، يساعد هذا التكنولوجيا في اكتشاف العوائق والابتعاد عن الاصطدام بالجدران أو الأشياء الموجودة في محيطها. وبعض وحدات النقل الآلية مزودة بأذرع روبوتية لالتقاط ونقل الأجسام الثقيلة، مما يجعلها مثالية للعديد من المهام التي قد لا يتمكن البشر من تنفيذها بأمان.

واحدة من الميزات الممتعة حول العربات ذاتية القيادة (AGVs) هي أنها يمكن أن تعمل طوال الوقت - نهارًا وليلًا ولا تحتاج إلى فترات راحة. هذا يسمح لها بنقل البضائع باستمرار، مما يتيح حركة المنتج بسرعة ومستمرة. في عالم لا ينام أبدًا، توفر العربات ذاتية القيادة للشركات الفرصة لتحقيق وفورات مهمة في الوقت والتكلفة والعمل 24/7.

العربات ذاتية القيادة (AGVs) أيضًا تقنية دقيقة جدًا. يمكن برمجتها للتحرك على طرق معينة وبسرعات محددة، مما يضمن نقل العناصر بأمان وفي الوقت المحدد. هذا مهم جدًا للشركات التي تحتاج إلى الحفاظ على كفاءة تشغيلها، تقليل الأخطاء وضمان أن كل شيء يصل إلى مكانه الصحيح.

طرق زيادة كفاءة العمل باستخدام العربات ذاتية القيادة (AGVs) بعض أنظمة AGVs، على سبيل المثال، مصممة للعمل بالتزامن مع أنظمة التخزين والاسترجاع الآلية، والتي يتم اختصارها عادة إلى AS/RS. تشمل هذه الأنظمة آلات قادرة على اختيار europallets من مناطق التخزين العالي ووضعها على العربات ذاتية القيادة التي تعمل بناءً على ID، والتي تنقل هذه europallets إلى وجهتها النهائية. يمكن لهذا العملية أن تقلل بشكل كبير من العمل المطلوب لنقل المواد من الصوت إلى خط الإنتاج، مما يؤدي إلى توفير الوقت وتقليل استهلاك الطاقة.

مُحفز آخر للإنتاجية توفره العربات ذاتية القيادة هو تحسين السلامة في مكان العمل. عن طريق إزالة الحاجة إلى وجود عمال يدويين لنقل الأشياء الثقيلة، يمكن للشركات تقليل احتمالية وقوع الحوادث والإصابات التي قد تحدث أثناء النقل. ليس فقط هذا يحافظ على سلامة العمال أنفسهم، ولكنه يمكن أيضًا أن يوفر المال لأصحاب العمل من حيث تكاليف التأمين والرعاية الصحية المتعلقة بالحوادث في مكان العمل.

إحدى أكبر مزايا العربات ذاتية القيادة (AGVs) هي الكفاءة والإنتاجية. تنفيذ استخدام النقل الآلي يساعد الشركات في نقل المواد على تقليل المدة اللازمة لنقل البضائع من مكان إلى آخر. وهذا يؤدي إلى زيادة الإنتاج وتحسين الأرباح للشركة، مما يمكّنها من تصنيع المزيد خلال نفس الفترة.

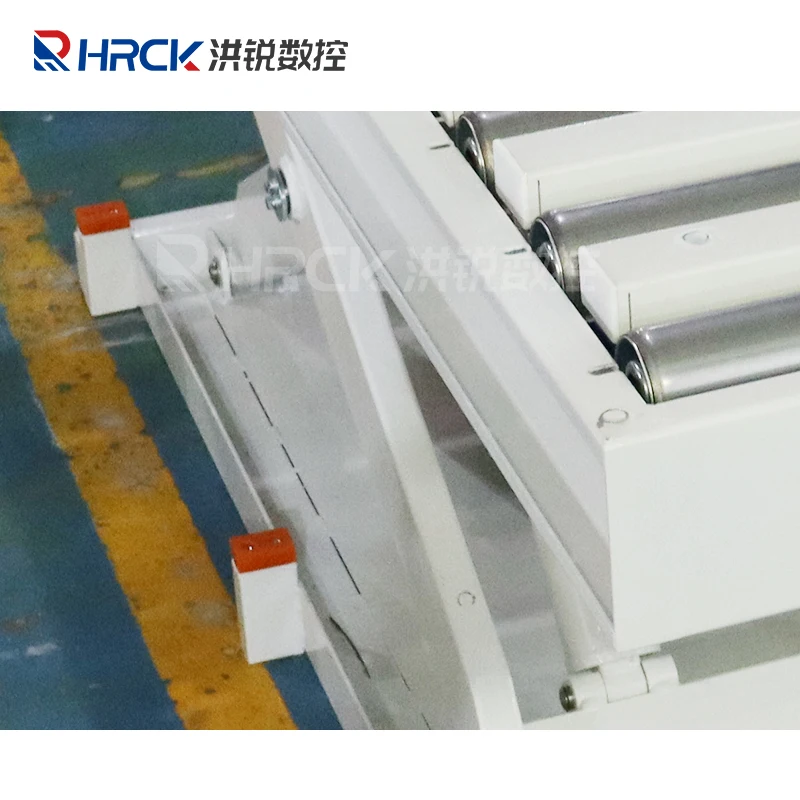

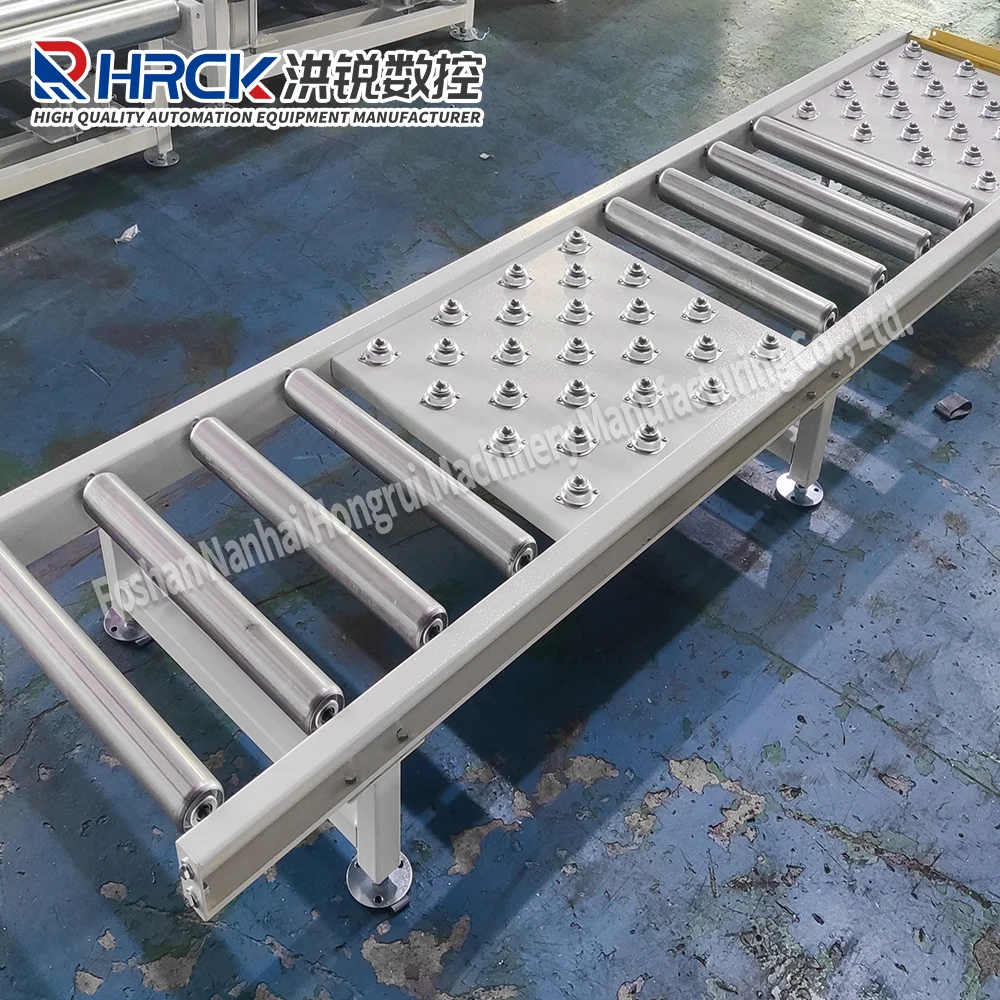

شركة فوشان نانهاي هونغروي لتصنيع الماكينات المحدودة متخصصة في مجال مركبات التوجيه الآلي (AGV) لتكنولوجيا أتمتة المصانع منذ أكثر من عقدٍ من الزمن. وبفضل خبرتنا التي تمتد لأكثر من عشر سنوات، نحن متخصصون في تصميم وتصنيع وتركيب مجموعة متنوعة من حلول الأتمتة، مثل خطوط النقل الدوّارة، والناقلات الأسطوانية، وكذلك وحدات التغذية الشاقولية (Gantry Feeders). ونقوم باستمرار بتحسين منتجاتنا وإدخال حلول مبتكرة سنويًّا لتلبية الاحتياجات المتغيرة للسوق. وتتجسَّد التزامنا بالجودة في شهاداتنا الصادرة عن هيئات الجودة المرموقة مثل ISO وTUV وSGS، والتي تضمن أعلى المعايير من حيث الموثوقية والأداء. وإذا اخترتم التعامل معنا، فستحصلون على دعم فني عالي الجودة ومنتجات مصممة خصيصًا لتحقيق أقصى كفاءة وجودة.

يعمل أكثر من ١٠ مهندسين معًا لإنشاء منتجات مبتكرة في سوق المركبات المُرشَدة آليًّا. ومن خلال البحث التكنولوجي المستمر وتحسينات المنتجات، نقدِّم حلولًا مخصصة تتماشى بدقة مع المواصفات المحددة للعملاء. فقدراتنا القوية في مجال البحث والتطوير لا تحسِّن التكنولوجيا فحسب، بل تحافظ أيضًا على تفوُّقنا في هذا المجال. وباستخدام أحدث التقنيات التي تكسر الحدود التقليدية، نقدِّم حلول أتمتة فعَّالة وموثوقة، تضمن الأداء الأمثل لكل منتج نُنتجه.

تتضمن مساعدتنا الشاملة بعد البيع تركيب النظام وتشغيله والحفاظ عليه. فريق خدمة الخبراء لدينا سريع في حل أي مشاكل قد تحدث أثناء تشغيل المركبة المؤتمتة التي تعمل بالدليل. وبفضل شبكة الدعم العالمية واستجابة سريعة لدعم التقنية والحلول، نحن نقدم خدمات احترافية وكفؤة أينما كنت. نحن ملتزمون بتقديم خدمة تضمن الاعتمادية طويلة الأمد لمعداتك، مما يعزز الكفاءة في الإنتاج ويضمن رضا العملاء. نحن نركز على احتياجاتك ونسعى لتخطي توقعاتك مع كل خدمة نقدمها.

لقد اكتسبنا كمية واسعة من الخبرة في مجال المركبات المُوجَّهة آليًّا ضمن شركة فوشان نانهاي أونورغروي لتصنيع الآلات المحدودة. ومنذ بداياتنا، ركَّزنا على تقديم حلول أتمتة مخصصة تتناسب بدقة مع المتطلبات الخاصة بصناعة النجارة، وتتضمن هذه الحلول أنظمة النقل والتجهيزات المعالجة وغيرها الكثير. ويتمتع فريقنا بفهمٍ شاملٍ للتحديات والمتطلبات المحددة المرتبطة بإنتاج المنتجات الخشبية. واستنادًا إلى سنوات الخبرة الطويلة في هذا المجال، نقوم بتصميم وتقديم حلول أتمتة فعَّالة وموثوقة ترفع من كفاءة الإنتاج وجودة المنتجات على حدٍّ سواء. ولا تقتصر خبرتنا على مساعدة العملاء في تحسين عمليات إنتاجهم فحسب، بل تمتد أيضًا إلى معالجة العديد من المشكلات التقنية الخاصة بهذا القطاع، مما يضمن توافق كل قطعة من المعدات تمامًا مع احتياجات صناعة النجارة. ويمكن لخبرائنا في مجال النجارة مساعدتك في تحقيق ميزة تنافسية لخط إنتاجك من خلال تقديم الدعم الفني المتخصص.