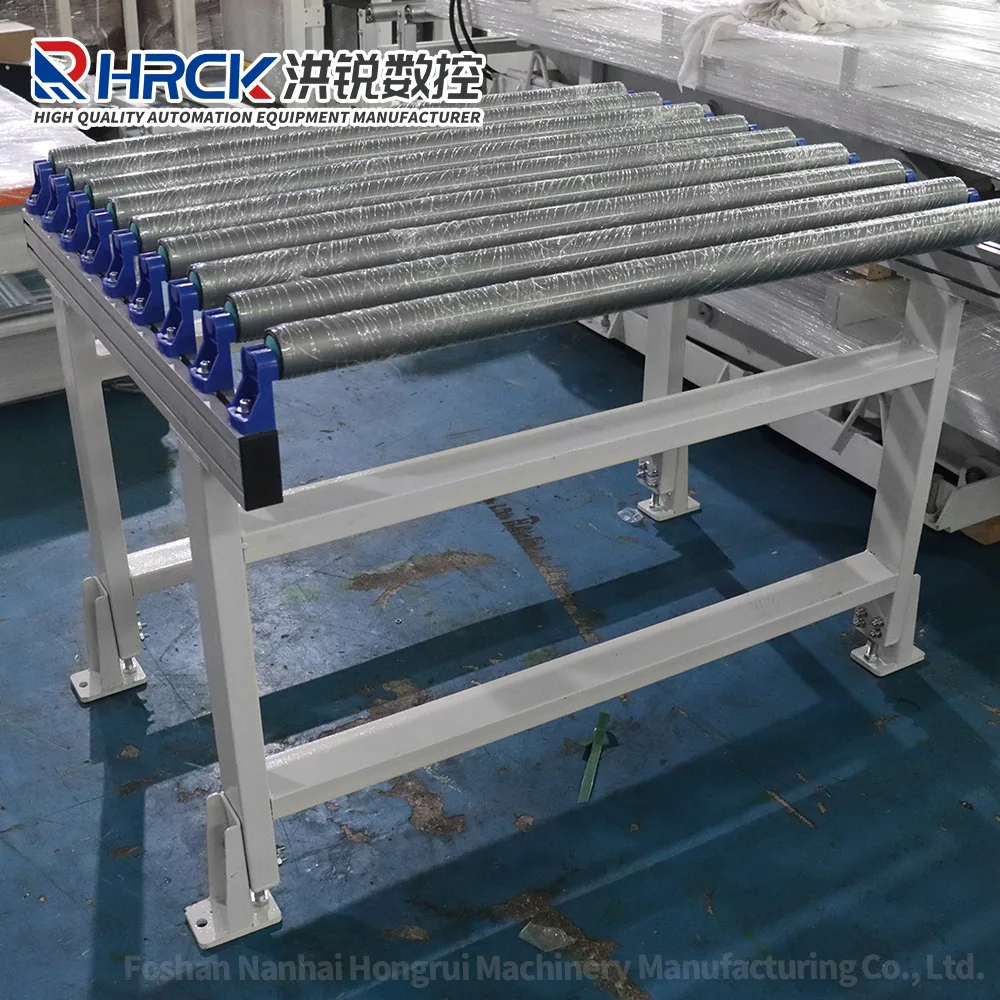

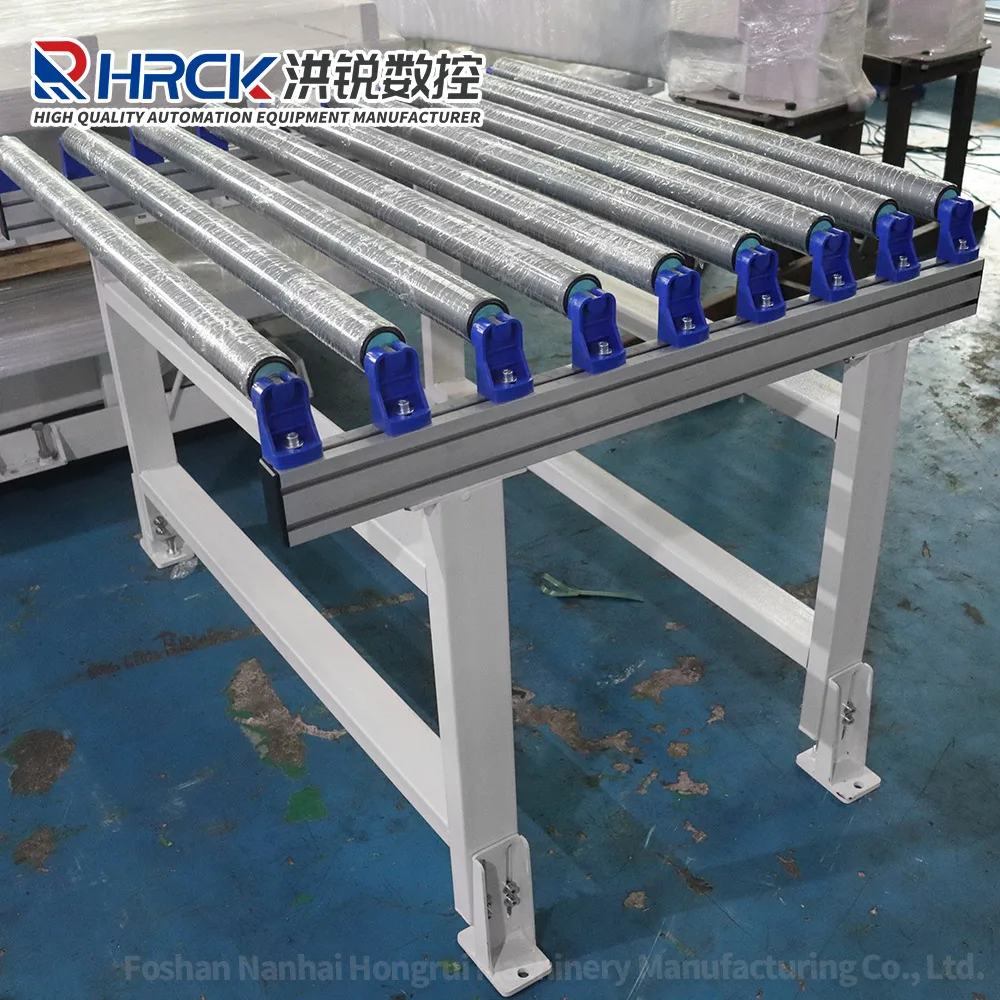

ناقل الأسطوانات: إنه جهاز خاص يسرع من نقل العناصر من مكان إلى آخر. هذا مشابه لطريق صغير ينقل المنتجات! هناك أنواع مختلفة من ناقلات الأسطوانات متاحة بأحجام وأشكال متنوعة. النوع الحديث من ناقل الأسطوانات الذي يحتوي على شاشة رقمية هو أمر رائع. وهذا يعني أيضًا أن الناقل يمكنه عرض معلومات حيوية على الشاشة. HRCK هي شركة تصنع هذه المنتجات. رافعة الجantry إذن دعونا نرى كيف تمنح الشاشات الرقمية وظائف أفضل لناقلات الأسطوانات وتُسهل الأمور!

تعني الشاشات الرقمية شاشة تُخبرنا عن حالة ناقل الحزام الخاص بك. يمكن لهذه الشاشة أن تخبرنا العديد من التفاصيل مثل معدل حركة الناقل، وكيفية عدد العناصر الموجودة حاليًا على الناقل ومدة بقائها. لدى العمال كل ما يحتاجون إليه أمامهم على شاشة واحدة بسيطة لمراقبة كل شيء. الآن، يمكن للعمال التعرف بسهولة أكبر على أي مشاكل قد تحدث وحلها في الوقت الفعلي باستخدام عرض رقمي. إذا تم توفير الوقت لهذا الإجراء البسيط، فإنه يوفر الكثير من الوقت ويسمح بتشغيل سلس جدًا لناقل الحزام بدون أي متاعب.

هناك العديد من الفوائد الرائعة لاستخدام الشاشات الرقمية في ناقلات الأسطوانات. كل شيء يبدأ بالاتصال الفعال داخل المصنع بين العمال. إذا كان بإمكان العمال مراقبة حالة الناقلة بسهولة ومراقبة حتى المشكلات البسيطة، فسيتمكنون من إبلاغ زملائهم بسرعة حول القضايا التي تحتاج إلى انتباه. تلك الإجراءات الجماعية تجعل من السهل على الجميع إصلاح المشكلات بشكل أسرع. ثانيًا، مع الشاشات الرقمية، يمكن للعمال إدارة ما هو موجود على الناقلة بكفاءة أكبر. يمكنهم رؤية الفور كم عدد المنتجات التي تم نقلها وأين يجب أن تذهب. تتبع هذه المعلومات يساعد الشركات على التخطيط الأفضل للمستقبل والاستعداد لتغيرات الطلب.

هناك العديد من الطرق المختلفة التي يمكن بها تحسين أنظمة ناقلة الأسطوانات بإضافة شاشات رقمية. واحدة من أكثر الطرق أهمية التي استفادنا منها هي تتبع أداء الناقل باستخدام بيانات الشاشة الرقمية. يمكن للشركات بعد ذلك النظر في هذه البيانات لاكتشاف التحسينات المحتملة لتشغيل الناقل. على سبيل المثال، إذا رأوا أن الناقل يبطئ عند نقطة معينة، يمكنهم التحقق ومعرفة السبب وراء ذلك. سيكونون قادرين بعد ذلك على إجراء التعديلات اللازمة بناءً على ذلك، مما يسرع من عمل الناقل ويضمن استمرار تشغيل كل شيء بسلاسة.

الطريقة الأخرى هي إدارة وقت التوقف؛ الوقت الذي لا يعمل فيه الناقل. يمكن للشركات استخدام البيانات في الشاشة الرقمية لجدولة الصيانة مسبقًا. وهذا يعني أنه يمكنهم حل المشكلات المحددة قبل أن يتوقف الناقل عن العمل. يقلل ذلك من وقت التوقف، مما يوفر الوقت فقط ولكنه يساعد أيضًا في توفير المال للشركات على المدى الطويل. أخيرًا، يمكن أن تكون الشاشات الرقمية مفيدة لمعرفة كمية الطاقة التي يستهلكها الناقل. عندما تكون الشركات على علم بهذه البيانات، يمكنها اتخاذ تدابير لتقليل استهلاكها للطاقة وحفظ المزيد من المال، مما ينفع ليس فقط الشركة، ولكن يساعد أيضًا البيئة.

تصميم ناقل الأسطوانات الحديث عرض رقمي أصبح جزءًا لا يتجزأ من كيفية عمل هذه الناقلات اليوم. يمكّن العرض الرقمي العمال من مراقبة كيفية عمل الناقل ويُظهر لهم كيفية إصلاح العطل عند حدوثه. كما يسمح لهم بإدارة المواد التي تتدفق عبر النظام، وتحسين أداء الناقل وتقليل استهلاك الطاقة. هذه والميزات الأخرى لأنظمة النقل الحديثة هي أمر حاسم. بدون شاشات رقمية، سيجد العمال صعوبة أكبر في اكتشاف المشكلات وإدارة المخزون. لذلك، قد لا يعمل الناقل بدقة مما يؤدي إلى خسارة المال للشركة.

الناقلات ذات العرض الرقمي تُبسط العمليات أيضًا، مما يجعل العمل أكثر كفاءة ودقة بشكل ملحوظ. يسمح هذه العروض الرقمية للعمال برؤية بسرعة ووضوح عدد العناصر التي تم نقلها عبر الناقل وجهتها. هذا يجعل إدارة المخزون والتخطيط المستقبلي أسهل对公司. بالإضافة إلى ذلك، تتيح هذه العروض الرقمية للعمال رؤية سريعة إذا كان الناقل يعمل بدون مشاكل. حل المشكلات بشكل أسرع ينفع الجميع. بشكل عام، ماكينة تجميع الخشب بالشفط توفّر في النهاية الوقت والمال والمصادر للشركات، مما يجعلها قطعًا حيوية من المعدات في العالم السريع الذي نعيش فيه اليوم.

فريقنا المختص بالبحث والتطوير، الذي يضم أكثر من ١٠ مهندسين ذوي كفاءة عالية، مُكرَّسٌ لابتكار منتجات جديدة تلبي احتياجات السوق، وتقديم حلولٍ مُخصَّصة تتماشى مع المتطلبات المحددة من خلال تحسين مستمر للمنتجات، وبإجراء أبحاثٍ متواصلة في مجال التكنولوجيا لضمان التفوُّق على المنافسين. وتتميَّز قدراتنا في أنظمة النقل الدوَّارة ذات العرض الرقمي القوي بالموثوقية والكفاءة في الحلول الأوتوماتيكية، مما يكسر الحدود المفروضة على التكنولوجيا التقليدية ويتبنَّى أحدث الاتجاهات التكنولوجية الرائدة، ما يضمن الأداء الأمثل لكل منتج نطوِّره.

لقد طوّرت شركة فوشان نانهاي هونورغروي لتصنيع الآلات المحدودة، وهي شركة متخصصة في أنظمة النقل الدوارة ذات العرض الرقمي، كميةً كبيرةً من المعرفة في قطاع صناعة الأخشاب. ونقدم منذ تأسيس شركتنا حلولاً مخصصة لأتمتة عمليات صناعة الأخشاب. فمنذ أنظمة النقل حتى معدات المعالجة، لدينا الخبرة الكافية لفهم احتياجاتها الخاصة. ويتمتع فريقنا بمستوى عالٍ من المعرفة بالتحديات والمتطلبات المرتبطة بإنتاج الأخشاب. وبفضل سنوات الخبرة الطويلة التي اكتسبناها في هذا المجال، نقوم بتصميم وتوفير أنظمة أتمتة قوية وموثوقة تحسّن كفاءة الإنتاج وجودة المنتج. كما أن معرفتنا الواسعة بهذا القطاع لا تساعد العملاء فقط على تحسين عملياتهم الإنتاجية، بل تُسهم أيضاً في معالجة العديد من المشكلات التقنية الخاصة بهذا المجال، وتضمن أن تكون كل أنظمتنا مُصمَّمة بدقة لتلبّي احتياجات صناعة الأخشاب. ويمكننا تقديم الدعم اللازم لك في قطاع صناعة الأخشاب ومنح خط إنتاجك ميزة تنافسية واضحة.

تشمل دعمنا ما بعد البيع لأحزمة النقل الدوارة ذات العرض الرقمي التثبيت والتشغيل والصيانة. ويستجيب فريق خدمتنا الخبير بسرعةٍ لأي مشكلات قد تنشأ أثناء التشغيل. ونوفر شبكة دعم عالمية تتيح لنا تقديم حلول فورية ودعم فني، أينما كنتَ. وتكمن التزاماتنا في تقديم خدمة سريعة واحترافية تضمن التشغيل طويل الأمد والمستقر لمعداتك، مما يحسّن الكفاءة ويرفع من رضا العملاء. وتتمحور خدماتنا حول تلبية احتياجاتك. ونحن مصممون على الوفاء بتوقعاتك أو تجاوزها.

لقد كانت شركة فوشان نانهاي هونغروي لتصنيع الآلات المحدودة في طليعة تكنولوجيا أنظمة النقل بالسلاسل الدوّارة الرقمية للمصانع لأكثر من ١٠ سنوات. وبفضل خبرتنا التي تمتد لأكثر من عقدٍ من الزمن، نحن متخصصون في تصميم وتصنيع وتركيب مجموعة واسعة من حلول الأتمتة، بما في ذلك نواقل الحزام وأنظمة النقل بالسلاسل الدوّارة ووحدات التغذية العلوية (الجسرية). وتُجرى باستمرار تحسينات على منتجاتنا، كما نبتكر حلولاً جديدة كل عام لتلبية المتطلبات المتغيرة للسوق. وتعكس شهاداتنا الصادرة عن المنظمات الدولية ISO وTUV وSGS التزامنا الراسخ بالجودة، وتكفل أعلى معايير الجودة والموثوقية. وباستخدامك لتقنياتنا ومنتجتنا المتفوِّقة، ستحصل على أقصى درجات الكفاءة والجودة.