Belt conveyors are the backbone of modern material handling, offering seamless transportation of bulk goods across industries. Our advanced belt conveyor systems are engineered for durability, efficiency, and adaptability, catering to diverse applications from mining to logistics. This article dives into the technical specifications, unique advantages, and real-world applications of our belt conveyors, ensuring you make an informed choice for your operational needs.

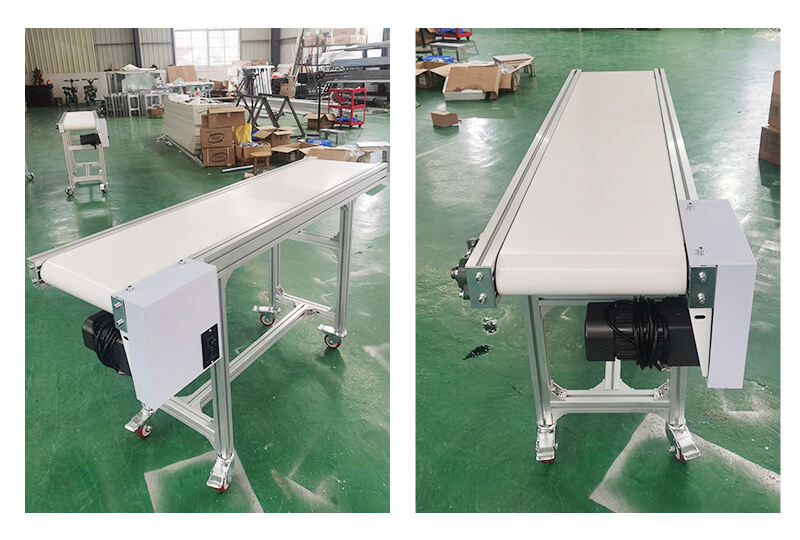

Our belt conveyor systems are designed to handle heavy loads while maintaining operational stability,There is still one year of warranty available. Key components include:

High-Strength Conveyor Belt: Made from wear-resistant rubber or PVC, ensuring longevity even under abrasive conditions.

Robust Frame Structure: Constructed with galvanized steel or aluminum alloy for corrosion resistance.

Customizable Configurations: Modular design allows adjustments in length, width, and incline angles .

Our conveyors excel in multiple sectors:

Manufacturing: Streamline assembly lines for automotive or electronics production.

Agriculture: Efficiently move grains, fertilizers, and packaged goods.

Warehousing: Optimize logistics with automated sorting and loading systems.

Energy Efficiency: Reduced power consumption with optimized motor designs.

Low Maintenance: Self-cleaning belts and sealed bearings minimize downtime.

Safety Compliance: Equipped with emergency stop buttons, anti-slip surfaces, and overload protection.

Custom Solutions: Tailored designs for unique layouts, including curved or inclined conveyors.