היא עובדת באותו אופן כמו קראנים ניידים וג'יבים, אבל האם אי פעם שאלת את עצמך איך הם EVEN מוזזים בתוך מחסנים גדולים? ובכן, זו שאלה מעניינת. אם כן, למה לא לשתף קצת חדשות חמות משל עצמי מזחלת גלגלים בגראוויטציה — להזיז דברים על הרצפה מהר יותר וקל יותר מזחלת גלגלים בגראוויטציה. זה HRCK מזger על בסיס כוח הכובד היא מכונה מהפכנית מאוד, היא גם מוסרת את המשקל מעובדים ומזיזה אותם מאחד צד למשנהו. אז זה גורם לשאלה הבסיסית: איך עובד מסלול תרמיל גравיטציה? הוא משתמש בגראוויטציה כדי לעזור פריטים לעבור מקצה אחד של המסלול ועד הסוף. הגראוויטציה רוצה לעבוד כך גם עבורך - כל עוד משהו שמונח (למעלה) על הרצפה עושה זאת בעדינות, אז הכל רולס חלק בצורה מספקת. העובדים במחסן יכולים להניע דברים כבדים ללא מאמץ, בלי אפילו להזיע כשהם שמים אותם על הקרקע בדרך קלה. זו בעצם שקע לגודל גדול

מגשיות גלגלים על בסיס כוח המשיכה גם מיטביות לעבודת אספנות מכיוון שאילו מצטיינות בהזזת חפצים כבדים, הן יכולות להפסיק ולהחזיק את הדברים במקום. יותר כמו עובד שמחבר חלקים יחד, כמו בבניית צעצוע או מuebl. במהלך תנועת המגש你可以 להוסיף לו חלקים נוספים כך שהחלקים ימשיכו להזוז במקטעים רצופים. נאמר כי תהליך אסיפת החלקים באמצעותו מהיר יותר מאחר ועובדים יכולים לסיים את משימותיהם בקלות ובמהירות. במקום לרוץ לכל מקום כדי למצוא חלק מסויים, הם יכולים פשוט לקחת אותו מהרצף של המגש

מרחב הוא מפתח בבית מחסן. אם אין מספיק מקום, זה עשוי להיות מעט מגביל. מצד שני, מגש גלגלים מבוסס על כוח המשיכה חוסך מקום מכיוון שלא דורש אחסון. ניתן להניח אותו בצורה מועילה לתוךAYOUT של המחסן כך שהדברים בכל קצה יהיו נגישי גישה, והם יישארו לך מקום לדברים אחרים. הHRCK מזגן על סמך כוח המשיכה מאפשר לעובדים להזיז את עצמם ברחבי המאגר בצורה קלה יותר ומעליל מקרים בהם עשויים להיתקל בדברים או בעובדים אחרים.

ניתן להוביל הרבה משקל במחיר בעלות נמוכה גם בהשוואה למינים אחרים של מכונות או ציוד. מגש רולרים לפי כוח הכובד מהחברה HRCK עשוי להיות אפילו זול יותר. הקנייה היא פעם אחת בלבד (והיא אמורה להחזיק לך מספר שנים). זה גורם לו להתאים לbusinessmen מחפשים לחסוך כסף בסופו של דבר. בנוסף, בגלל שהמגש הוא עם תחזוקה מזערית, העלות הפעלה גם היא מזערית. זה נותן לעסקים את האפשרות לנצל את כספם בתחומים אחרים, להשקיע אותו במקום לתקן.

הממשות של מזחלת גלגלים בגראוויטציה היא שהיא צריכה להחליק בקלות, לא להיתקע ודורשת מעט מאוד תשומת לב כדי לשמור על המרכיבים. זה הסיבה שעובדים יכולים להימנע מתהליך פתרון בעיות אם הם ממשיכים להזיז חומר כל הזמן. גראוויטציה כל הדרך על המזחלת הזו, אז אין מנועים או ציוד חשמלי לבדוק כל שבוע. זה HRCK חבל מוביל למכסה קצה מאפשר לעובדים להשלים את עבודתם ללא הפסקות.

אנו מספקים מגוון רחב של שירותים לאחר המכירה, הכוללים התקנה וכניסה לתפעול, וכן תחזוקה. צוות השירות שלנו בעל ניסיון רב ומעתיר במהירות לכל בעיה שעלולה לצוץ במהלך הפעלה. עם רשת תמיכה גלובלית, אנו מספקים תמיכה ופתרונות למסועי התנעה מסוג Gravity Rollers בכל מקום בו אתם נמצאים. אנו מחויבים לספק תמיכה יעילה ומקצועית המבטיחה את אמינות הציוד שלכם, מה שיעזור לשפר את יעילות הייצור ואת שביעות רצון הלקוחות. אנו קשובים לצרכים שלכם ופועלים על מנת לעלות על הציפיות שלכם בכל שירות שאנחנו מספקים.

צוות המחקר והפיתוח שלנו, שכולל יותר מ-10 מהנדסים בעלי ניסיון, מיועד לפיתוח מוצרים חדשים מסוגלים לענות על צורכי השוק, להציע פתרונות מותאמים לדרישות הספציפיות, לשפר באופן מתמיד את המוצרים וכן את המחקר הטכנולוגי, ולשמור על עליונות תחרותית באמצעות יכולות מחקר ופיתוח חזקות. על ידי קידום מגמות טכנולוגיות, דחיקת גבולות החשיבה הקונבנציונלית, אנו מביאים רולר קונוויאור גרביטציה יעיל ואמין, המבטיח ביצועים גבוהים ביותר בכל עיצוב מוצר.

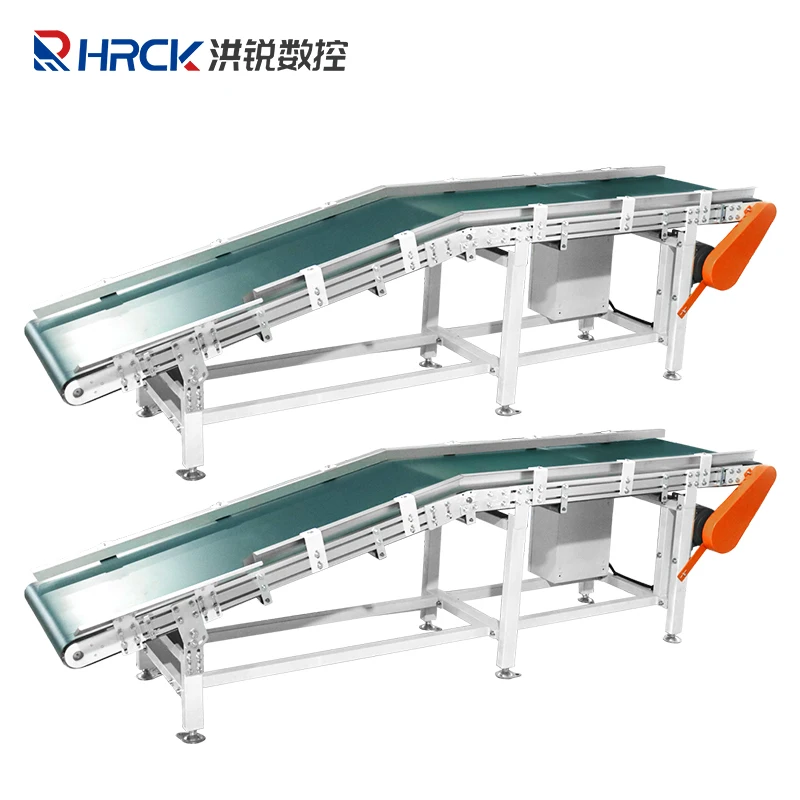

פושאן נאנהאי הונגרואי מכונות ייצור תאגיד, Ltd כבר בגרביטציה רולר מובילה של טכנולוגיית אוטומציה מפעל במשך יותר מעשור. עם ניסיון של יותר מעשור, אנו מתמחים ביצירת, ייצור ויישום של מגוון פתרונות אוטומציה, כגון קווי גלגול חגורות מובילים, מובילים גלגלים, כמו גם מזינים גנטרי. אנו משפרים את המוצרים שלנו באופן מתמשך ומציגים פתרונות חדשניים מדי שנה כדי לענות על הצרכים המשתנים של השוק. מסירותנו לאיכות מובהקת בתעודות האיזו, TUV, SGS ו- ISO שלנו, אשר מבטיחות את הסטנדרטים הגבוהים ביותר באמינות ביצועים. אם תבחר בנו, אתה מקבל סיוע טכני באיכות גבוהה ומוצרים שנועדו לייעל יעילות ואיכות.

ב-Gravity roller conveyor פיתחנו ידע רחב בתחום עיבוד העץ. אנו מספקים פתרונות אוטומציה מותאמים לפעולות עיבוד עץ מאז היום הראשון שהחלנו לפעול. ממערכות הובלה ועד ציוד לעיבוד, אנו מומחים בהבנת הדרישות המיוחדות שלהם. לצוות שלנו יש ידע מעמיק באתגרים והדרישות הספציפיים לייצור עיבוד עץ. אנו יוצרים ומממשים מערכות אוטומציה יעילות ואמינות שמשפרות את יעילות הייצור ואת איכות המוצרים. הידע המתמחה שלנו לא רק עוזר ללקוחות לאופטם את התהליכים שלהם, אלא גם פותר את האתגרים הטכניים הספציפיים לתעשייה שלהם, ומבטיח שכל מערכת תהייה מיושרת באופן מושלם לדרישות עיבוד העץ. הצטרפו אלינו כדי לקבל תמיכה בתחום עיבוד העץ ולתת לקו הייצור שלכם יתרון תחרותי.