Efficiency is very crucial for producing goods in a factory as we think at HRCK. An efficient process means that everyone works better together and things get done faster. For this reason, we worked on a special system — the wood panel automatic gantry loading system. The first step is a system that intends to simplify how wood panels can be positioned and slotted onto the machines which use it.

If you are doing all of this by hand, the time and effort involved in handling wood panels can be significant. While the work of lifting heavy panels is hard, it can also be dangerous and cause accidents or injuries. This is the view of the automatic gantry loading system wood production line has achieved, making it It's a lot easier and faster (and safer) to run those panels around.

Larger–A big crane and automatic arm for two panels at once. That in turn means staff no longer have to handle large panels on their own and therefore also reduces the potential for injury. The system consists of special sensors and intelligent software that allows it to move the panels very precisely. In other words, because it is easier to get things done in a timely manner – and with fewer mistakes — construction errors are reduced or eliminated before materials which would be wasted if an error occurred had already been used.

This is not all, we can have multiple benefits while processing the wood panels with the gantry loading system of HRCK. To begin with, it is able to function alongside different styles and sizes of panels which allows the system perform in countless rooms for numerous purposes. This is why it works well for many manufacturing requirements.

Second, that it can pick up two panels simultaneously to speed the loading of them onto machines. This makes the entire processing line more efficient and faster, which allows us to complete more orders in less time without sacrificing quality fencing. This HRCK wood production machinery in turn allow us to be at the forefront of our production schedule and better answer customer requests.

It is with the use of our wood panel loading system that all other machines function to have a wonderful output in manufacturing line. You can easily coordinate between the gantry loading system and CNC machine. So the loading arm knows exactly from where to put in panels. This means far fewer employees are required to intervene, keeping them safer and able to focus on their work.

Advanced sensors and technology guarantee precise handling of the panels for every single movement in their wood panel automatic gantry loading system. These sensors are there to measure size as well location on the module for packing in such a way that it is picked up by arm into itself and not goes anywhere else. Software guides the movement of crane and arm, to ensure that they put the panels on CNC's machine wood robot in proper place.

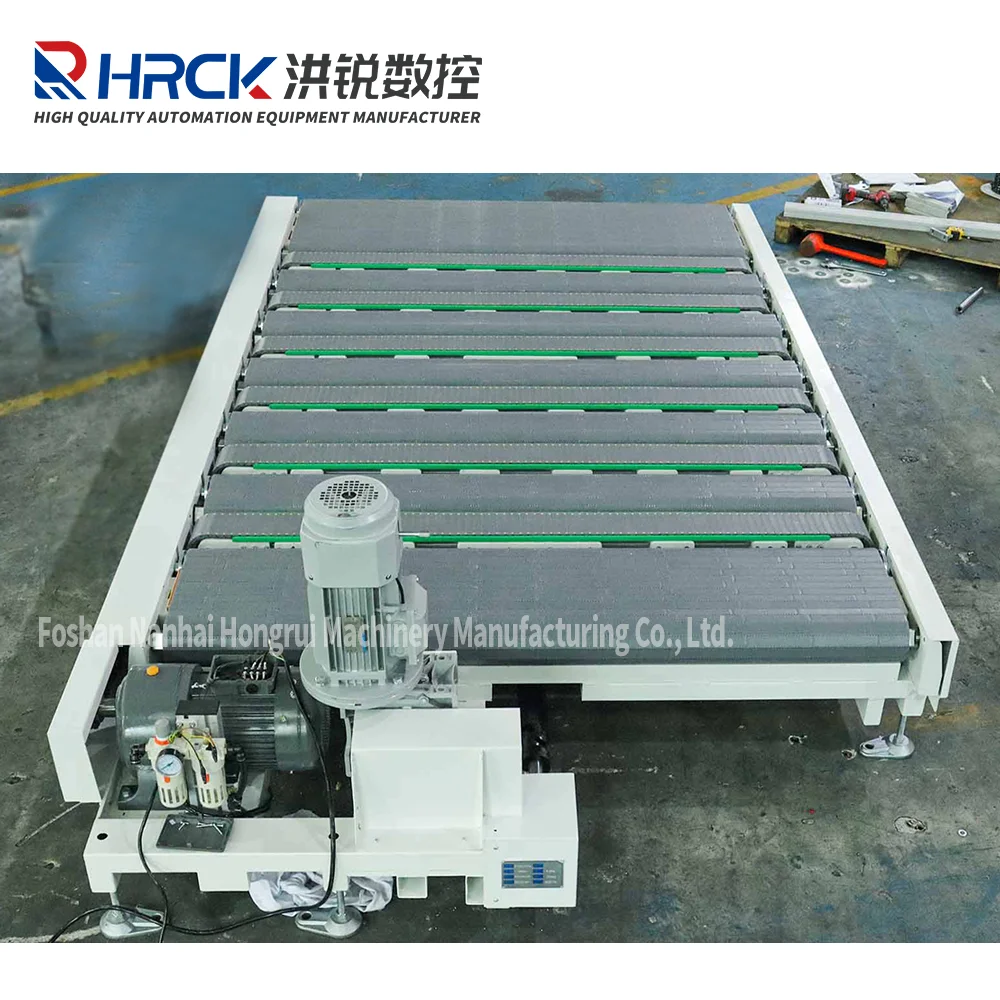

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is a leader in manufacturing automation technology. We have over 10 years of expertise designing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are continually upgraded and we introduce new solutions each year to keep pace with the changing market needs. Our ISO, TUV and SGS certificates reflect our dedication to quality, which ensures the highest standards of reliability and Wood panel automatic gantry loading. We offer high-end products and technology that optimize efficiency and quality.

Our team of research development comprised of more 10 highly skilled engineers is dedicated to creating new products that meet market needs offer tailored solutions that meet the specific requirements through constant product improvement research into technology ensure that stay ahead robust Wood panel automatic gantry loading capabilities offer reliable efficient automation solutions breaking the boundaries of traditional technology leading technological trends This ensures optimal performance for every product develop

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed significant expertise in the woodworking industry. We've been providing custom automation solutions to woodworking businesses since the day we started. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is familiar with the demands and difficulties of production woodworking. We create and implement efficient and robust automation systems that enhance production efficiency and the quality of products. Our specialized knowledge will not only help our clients improve their processes for production, but also tackles the technical challenges specific to their industry, ensuring that each system perfectly aligns with the needs of woodworking. We can provide you with professional assistance in the woodworking sector, giving your production line an Wood panel automatic gantry loading in the market.

Our extensive after-sales assistance includes installation of the system commissioning it and maintaining Our expert service team is quick to resolve any issues that may Wood panel automatic gantry loading while operating With a global network of support and a rapid response time to tech support and solutions no matter where you are We are committed to providing professional and efficient service that will ensure the long-term reliability of your equipment This improves efficiency in production and ensure satisfaction for customers We are attentive to your needs and work to exceed your expectations with every service that we offer