When you think of a factory, you probably picture a place with certain equipment and machines, working conveyor belts, and plenty of workers running around. Imagine a conveyor belt is like a highway that takes stuff from point A to point B in the factory. It helps with the prompt and efficient transfer of goods, and so things can be produced more quickly. It seems like a small part, but a conveyor system roller is a very important part of this conveyor belt system. The roller is a wheel used to obj the conveyor belt. The HRCK roller conveyor system also helps keep the belt moving, because otherwise it would be so heavy that it would take too much energy to turn around. Pretend on this scenario Push a small heavy box without wheels! But with the rollers slotted in, the belt can smoothly roll across them. This sliding lets factories act quicker and similarly to before, which is even more of a value!

With different quality rollers, some are made better than others, and that can make a huge impact on how well everything functions. There are many benefits for a factory when it uses good quality rollers. HRCK heavy duty roller conveyor lasts longer and can support heavier loads without breaking. People realize that this means that the factory is less likely to encounter delays due to broken machinery. Also, investment in good quality rollers will also pay off in the long run. The cheaper rollers have proven to wear faster than the more quality rollers. Instead of always buying cheap rollers (sometimes ending up with more cost in the long run), a business can opt to purchase quality rollers and be confident that they will work away at the task at hand. This means that they can put on the rollers without any changes in high frequency.

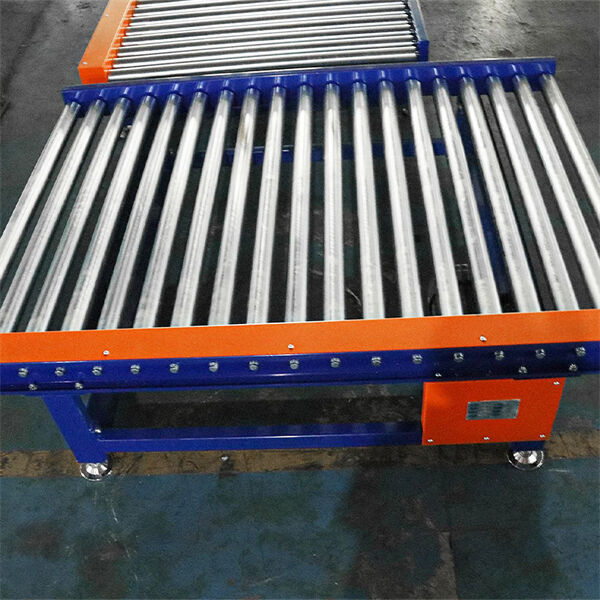

Rollers can be made from steel, plastic, or rubber. Each material has different characteristics and benefits, and typically, the best option depends on what they are required to transport. For instance, steel rollers are tough and powerful, which makes them great for heavy loads. On the other hand, plastic or rubber rollers are softer and flexible, which makes them better suited for lighter loads that need to be delivered without damage.

It is also very important the design of the roller. To allow it to roll smoothly on the conveyor belt, the roller should be round. If there are any rough, or sharp parts on the roller, they can injure the belt, making it last a shorter time. A well-designed HRCK roller conveyor is also be easy to clean and maintain to allow work in the factory in a high-percentage capacity.

Roller technology is also improving as technology continues to advance. At present, roller design is flooded with a number of new concepts and innovations to improve the functionality of conveyor systems. What are modern rollers like: For example, some modern rollers come with sensors built into them. These are able to sense when the rollers require lubrication or replacement. This can also be useful in terms of simplifying the maintenance process, thus minimizing the risk of equipment malfunction.

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable Conveyor system roller ensuring the highest performance for each product design

We have accumulated a vast amount of knowledge in the woodworking sector at Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on providing customized automation solutions that are tailored to the particular requirements of woodworking, ranging from conveyor systems to processing equipment. Our team is well-versed in the challenges and needs of production woodworking. With years of experience in the industry We design and develop effective, reliable automation systems that enhance production efficiency and the quality of products. Our knowledge of the industry will not only help our clients improve their Conveyor system roller, but addresses many industry-specific technical challenges and ensures that every equipment is fully compatible with woodworking needs. Our woodworking experts will provide your production line with an edge with our expert support.

We offer a variety of after-sales support that include installation, commissioning and maintenance. Our Conveyor system roller is highly trained and responds quickly to any issues that might occur. With a global network of support We provide prompt technical assistance and solutions no matter where you are. We're dedicated to providing professional and efficient support that guarantees the stability of your equipment. This will enhance the efficiency of production and improve customer satisfaction. Our services are designed to meeting your needs. We are determined to meet or exceed expectations.

Conveyor system roller has been at the forefront of manufacturing automation for more than 10 years. We have over 10 years of expertise developing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are constantly refined and come up with new ideas every year to meet the ever-changing needs of our customers. Our commitment to quality is evident in our ISO, TUV, SGS, and ISO certifications. They guarantee the highest standards of quality and performance. When you work with us, it is possible to get top-quality technological support and products specifically designed to enhance efficiency and quality.