Conveyor rollers are round pieces of machinery that rotate on a pole and are crucial components of factories. The rollers assist in moving things along a production line, which is like a moving track that produces goods. It could be of plastic, metal or rubber. Other types of roller feature specialty grooves or designs to prevent items from falling out while they are being transported on the conveyor.

The use of conveyor rollers have their one of the most significant benefits which is they make the workers more productive. Workers would typically need to lift and transport items by hand, which is very time- and energy-consuming. But with the use of conveyor rollers, they can allow the rollers to do this heavy task for them. This not only saves a lot of time but also enables the workers to put their energy into other important tasks that needs their focus and skills.

Conveyor rollers also help to minimize the injury risk of the workers, which is another of its many great benefits. Lifting heavy objects over and over can be rough on the body, particularly the back. It can cause injuries — back strain, for instance — that can make it difficult for workers to do their jobs. By letting conveyor rollers do the heavy lifting, workers are safe from these injuries while they work.

The proper selection of conveyor rollers is critical to ensuring that production runs smoothly and efficiently. Selecting the right conveyor rollers also requires consideration of many factors. These factors combine to help determine things like the weight and size of items that can be moved along the conveyor, the necessary speed of the conveyor, and the environment in which the conveyor will operate.

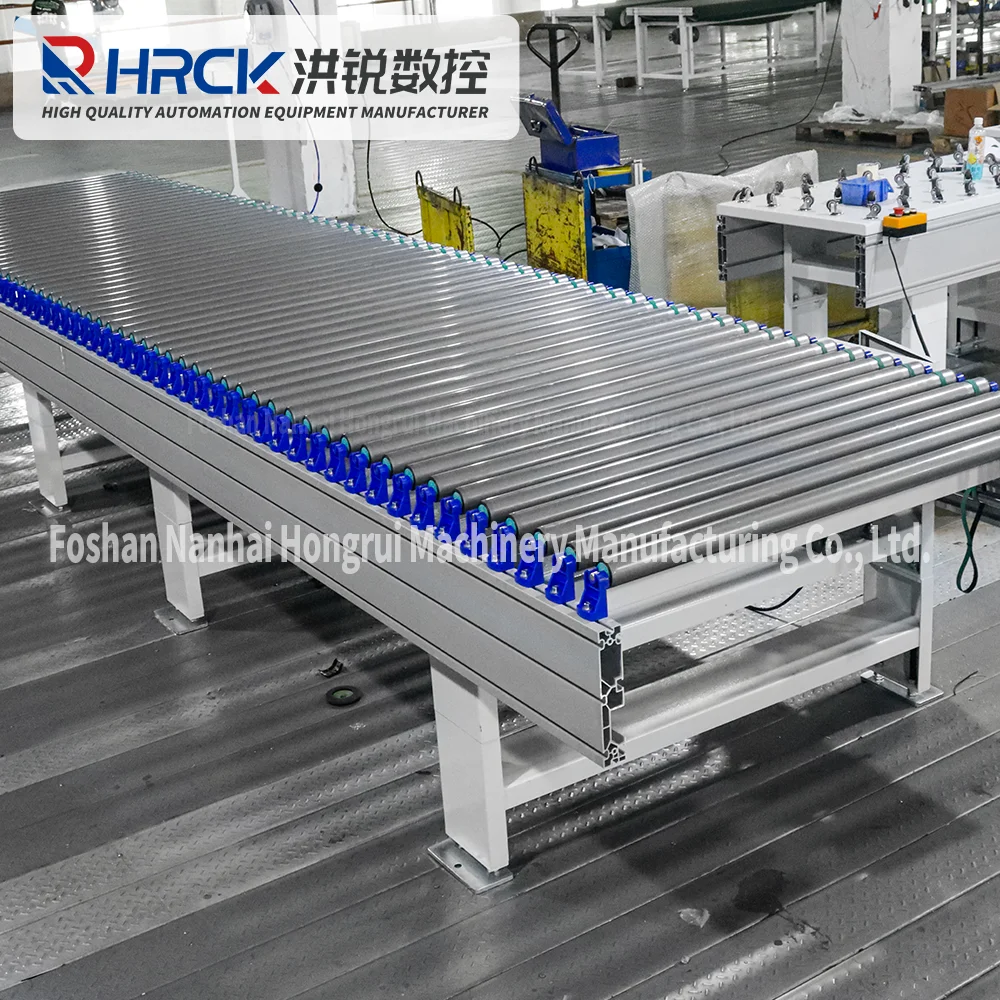

HRCK provides several conveyor roller options to fulfill various requirements. HRCK can provide conveyor rollers that will help them as they weigh a little more. If a customer requires a conveyor system that will function effectively in a dusty or dirty environment, HRCK can offer rollers that are sealed or coated to guard against dirt and debris.

Ensuring smooth operation of supply chain is crucial in helping companies to reduce costs and be maximally efficient. HRCK offers custom conveyor roller systems for customers to transport products on the production line effortlessly and smoothly. This is a critical for customer satisfaction as it ensures that products are completed and sent out as quickly as possible.

HRCK designs the conveyor roller system also that blends well with other production equipment. That could include machines such as automated sorters or packaging systems. HRCK can afford to automate, putting together a seamless production line that makes manual help from workers redundant and therefore improves general efficiency and turns around.

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed significant expertise in the woodworking industry. We've been providing custom automation solutions to woodworking businesses since the day we started. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is familiar with the demands and difficulties of production woodworking. We create and implement efficient and robust automation systems that enhance production efficiency and the quality of products. Our specialized knowledge will not only help our clients improve their processes for production, but also tackles the technical challenges specific to their industry, ensuring that each system perfectly aligns with the needs of woodworking. We can provide you with professional assistance in the woodworking sector, giving your production line an conveyors rollers in the market.

conveyors rollers has been at the forefront of manufacturing automation for more than 10 years. We have over 10 years of expertise developing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are constantly refined and come up with new ideas every year to meet the ever-changing needs of our customers. Our commitment to quality is evident in our ISO, TUV, SGS, and ISO certifications. They guarantee the highest standards of quality and performance. When you work with us, it is possible to get top-quality technological support and products specifically designed to enhance efficiency and quality.

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable conveyors rollers ensuring the highest performance for each product design

Our conveyors rollers after-sales support includes installation, commissioning and maintenance. Our expert service team responds promptly to any issues that may arise in the course of operating. We offer a worldwide support network that allows us to provide prompt solutions and technical support, no matter where you may be. Our commitment to prompt and professional service ensures the long-term, stable operation of your equipment, improving efficiency and satisfaction of customers. Our services are geared towards fulfilling your requirements. We are determined to meet or exceed expectations.