Sick of having to lift heavy boxes and move materials around in your factory or warehouse? If yes, you must know about HRCK’s gantry crane! A first of its kind, helping you easily transport things in and out.

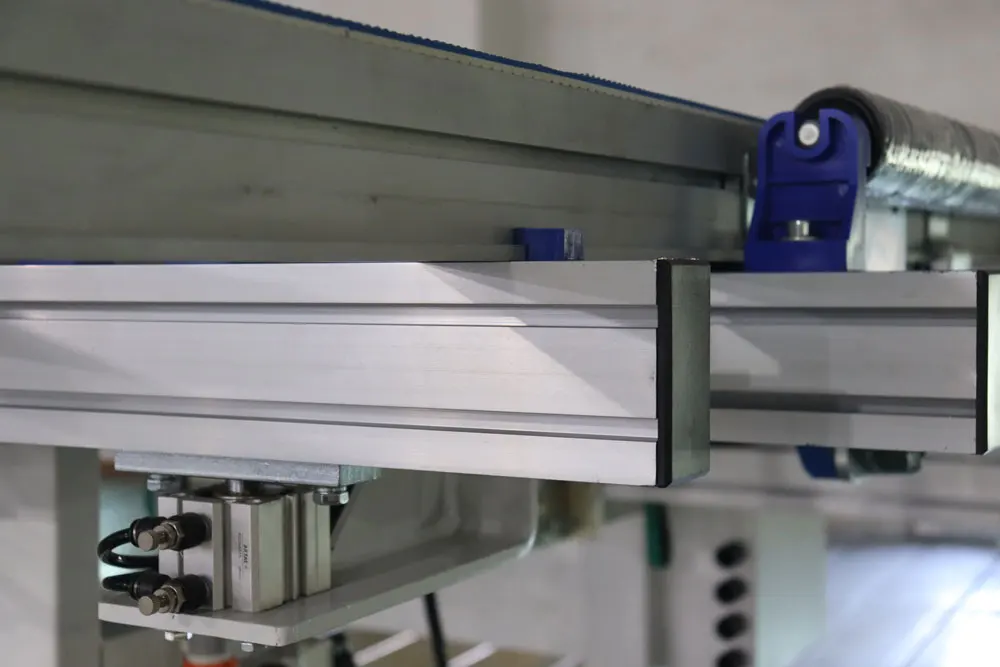

A wooden doors production line is a unique variety of conveyor belt with a curved shape. Having this unique design allows it to help carry materials around corners and turns in a smooth manner. Unlike the straight conveyors these are made to take the narrow spaces and complex designs hence these have a lot of relevance in busy factories and warehouses.

With the help of curve conveyors, you can complete your work faster. In addition to allowing you to transport things around the corners, they also help you keep your manufacturing process running smoothly. This allows you to use your time more effectively and achieve more! While they occupy less space, they are also great for adding curvature into the design. This helps ensure that no space goes unused, allowing you to better utilize your factory or warehouse.

At HRCK, we know that every factory has unique requirements. That’s why we provide you with the opportunity to tailor our curve conveyors to your unique needs. You can select various options for how rapidly the conveyor moves, how wide it is and how tight the curve can be. We also have additional features, such as side rails that keep items in place, cleats that grip materials and covers that secure your items during transport.

Well, the majority of industry experts agree that curve conveyors are by far one of the best choices! Modern Manufacturing: Grace Turner of Automation World It points out that businesses are transitioning toward much more flexible and more integratable systems. Machines also need to work quickly and safely with a wide range of materials. Curve conveyors can help achieve this, made easy.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is a leader in manufacturing automation technology. We have over 10 years of expertise designing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are continually upgraded and we introduce new solutions each year to keep pace with the changing market needs. Our ISO, TUV and SGS certificates reflect our dedication to quality, which ensures the highest standards of reliability and curve conveyor. We offer high-end products and technology that optimize efficiency and quality.

Over 10 engineers work together to create innovative products that align to market dem offer customized solutions to meet specific needs through continuous product improvements research into technology keep edge extensive RD capabilities deliver reliable efficient automation solutions breaking the boundaries of conventional technology leading technological trends This ensures the highest performance of every product curve conveyor

We offer a variety of after-sales support that include installation, commissioning and maintenance. Our curve conveyor is highly trained and responds quickly to any issues that might occur. With a global network of support We provide prompt technical assistance and solutions no matter where you are. We're dedicated to providing professional and efficient support that guarantees the stability of your equipment. This will enhance the efficiency of production and improve customer satisfaction. Our services are designed to meeting your needs. We are determined to meet or exceed expectations.

At curve conveyor we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.