This is nothing but magic — If I tell you how goods enter in that store which are claimed to be necessities, HRCK conveyor line will fail your logic tooynchronous. but hell it is HELL LOT OF HARDWORK! A gimmick track is one of the element in this regards. The conveyor line is a system of moving various parts without human intervention. This allows business to run faster and cheaper, so as do not crash during the operation of different services. Learn more about how this conveyor range could help your business operate both better and faster, with the following article HotRail HRCK Conveyor Line: Better Faster Efficiency. idea.

This won't make them move organically down a conveyor line, but it will help sizing associates sort products in motion more easily at their facilities. Which in turn results into The workers needing the boxes not having to haul them around and it saves mounds of time as well energy. Instead of breaking their backs by picking (or packing boxes), logistic conveyor line are free to do other important tasks like quality control or typically more meaningful interactions with customers. And we will work together constructively. What is more, because the conveyor never tires like a human it can work 24 hours without maintenance requirements. The business can create extra products and provide for the consumer demand.

Using one or more conveyor lines is really great bonus when businesses are looking at having to hire on many extra hands just to move material. The conveyor line moves so quickly and may even relocate products within the blink of an eye which makes it feasible to handle more parcels through premier business as well dispatch plenty of shares without hiring additional guy slot. HRCK Sawing machine conveyor line means more money, with minimal cost to the business. If a company can produce more, it is able to sell most and increase its profits which ultimately benefits all.

This means some human lead manual handling of products where people tend to drop or break things while sending and transferring stuff leading upto errors and broken items. A conveyor line removes these discrepancies, making sure that the products are delivered in one piece to their proper location. Weight sensors are also an addition to some checks such as barcode scanners which will increase the efficacy of customer products and prevent any harmful substance from entering back into trade centers. When businesses check for any exceptions, this will allow HRCK conveyor lift to avoid mistakes in the first place and, thus make less errors which can only lead up to higher quality products delivered.

A conveyor line provides the even greater pragmatic advantage of enhanced safety in whatever type of work setting. The system helps to shoulder the lion's share of this punishment, such that you may not suffer from strains and sprains too many times due to excessive bending over and lifting. You can also put safety barriers and other protection around the conveyor line to make sure everyone works in an accident-free zone. This will help you keep the workers well shielded from whatever but at this kind maintains a significantly more inviting working surrounding. The business also benefits from having employees who are safer at work, because logistic conveyor line means that workers can focus better.

Our extensive after-sales assistance includes installation, commissioning, and maintenance. Our customer service staff is highly educated and is Logistics conveyor line to respond to any problems that may occur. With our global support network We provide prompt technical support and solutions no matter where you are. We're committed to providing professional and efficient service that ensures long-term reliability of your equipment. This will enhance efficiency in production and ensure satisfaction for customers. We take your requirements into consideration and aim to meet your expectations with each service we offer.

We have accumulated a vast amount of knowledge in the woodworking sector at Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on providing customized automation solutions that are tailored to the particular requirements of woodworking, ranging from conveyor systems to processing equipment. Our team is well-versed in the challenges and needs of production woodworking. With years of experience in the industry We design and develop effective, reliable automation systems that enhance production efficiency and the quality of products. Our knowledge of the industry will not only help our clients improve their Logistics conveyor line, but addresses many industry-specific technical challenges and ensures that every equipment is fully compatible with woodworking needs. Our woodworking experts will provide your production line with an edge with our expert support.

Over 10 engineers work together to create innovative products that align to market dem offer customized solutions to meet specific needs through continuous product improvements research into technology keep edge extensive RD capabilities deliver reliable efficient automation solutions breaking the boundaries of conventional technology leading technological trends This ensures the highest performance of every product Logistics conveyor line

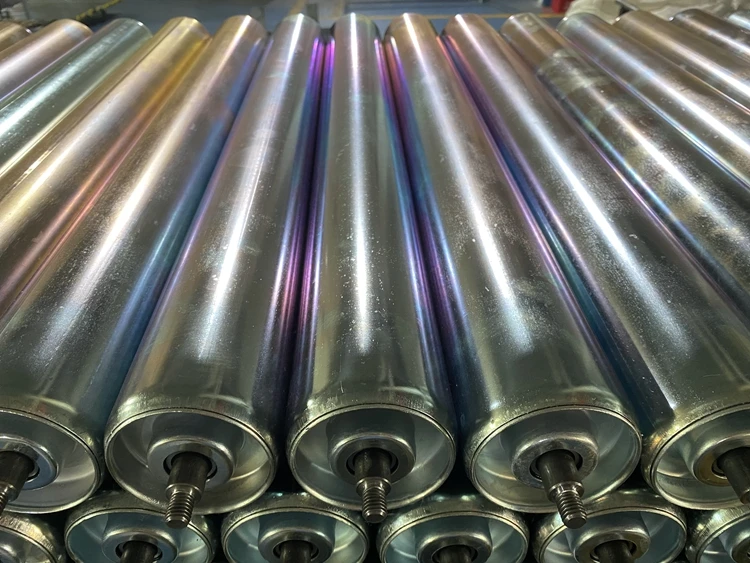

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of manufacturing automation for more than a decade. With over a decade's experience, we have a specialization in designing, manufacturing, and constructing a broad range of automated solutions, including conveyor belts, roller lines, and gantry feeders. We continuously refine our products and introduce innovative solutions annually to keep up with the changing demands of the market. Our ISO, TUV and SGS certifications demonstrate our commitment to quality and ensures the highest standards of reliability and performance. Our customers will benefit from high-end technology and products that Logistics conveyor line efficiency and quality.