We at HRCK know that transporting products can be a huge responsibility, especially if you have a large number of items to move from one place to another. This process can demand a large amount of time and effort, which is the reason we developed the band edg conveyor. A conveyor line is like a magic belt that carries items from one location to another without the need for humans to transport them. But imagine a long belt that is in a circle or back and forth, and you can just put your things on it. This helps as it saves everyone's time and energy through the process.

Automated conveyor line is better than a normal conveyor line. That makes everything automatic, and people need not do anything at all! For example, suppose you have a number of boxes to be transferred from one side of a big room to the other side. On a typical conveyor line, workers would have to place the boxes on the conveyor, and then take them off when they got to the end. But with an automated conveyor line, a single machine can accomplish all of that independently! It can load up, move and deliver the boxes autonomously, without human assistance. That frees up people to concentrate on other vital things and speeds up everything!

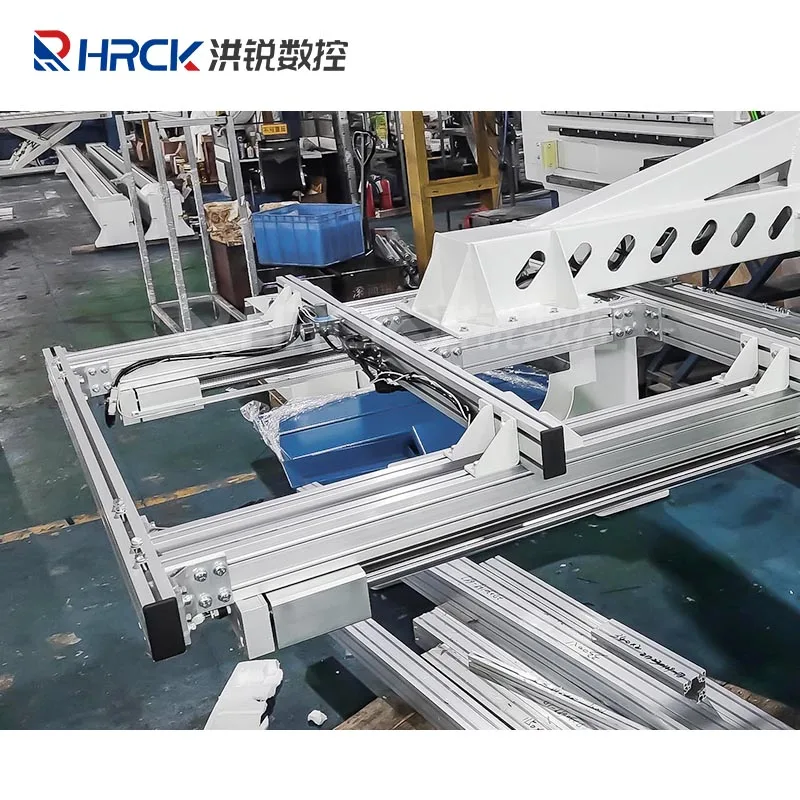

In a large plant, all products are complex and difficult to manufacture. This process is very time and energy-intensive as there are many steps to create items. This is why adjustable roller conveyor technology line is so exciting to us! Organising processes: By adopting conveyor lines in factories, smaller processes become organised and eventually become a line where process x flows into process y. That means less waiting around for things to get done, and more work getting accomplished. If every step welds together nicely, it also helps reduce errors that may arise in the fabrication process. This makes it easier to make everything work well and to get factories going.

If you would like to see even more benefits from an automation solution, you might consider investing in integrated conveyor lines within your warehouse.

If you have a large warehouse, then you already understand how challenging it can be to keep everything organized. A lot of things to store and easily it can get messy or get lost. But a conveyor line makes it easier to keep your hands on it all. The conveyor line also allows you to easily move items around without having to keep throwing things on top of a big stack. This is particularly beneficial when you must carry extremely heavy objects, which can be quite burdensome for lifting. And those heavyweight go the conveyor line instead. It also aids in maintaining everything in one place and easy to access. You no longer have to roam the warehouse looking for something, you simply follow the conveyor line to where you need to go! That way, you can quickly access what you need and maintain a clean warehouse.

Logistics is a fancy word meaning “moving things from one location to another. It is crucial in many jobs, from shipping products to retail businesses.” This is why a conveyor line system can be so helpful for a wide range of different businesses. Conveyor Lines Mean A Simplified Process Of Moving ThingsIntermediaries greatly simplify the entire operation of relocating things from one area to another by using conveyor lines to move items. When items are moved, on a conveyor line it is easier to keep track of them, which can decrease errors. This also ensure that everything is done on time, which is crucial in business. Also, a conveyor line isenergy-efficient, which is always a plus — for the place and time money is saved!

We offer a variety of after-sales support that include installation, commissioning and maintenance. Our conveyor line is highly trained and responds quickly to any issues that might occur. With a global network of support We provide prompt technical assistance and solutions no matter where you are. We're dedicated to providing professional and efficient support that guarantees the stability of your equipment. This will enhance the efficiency of production and improve customer satisfaction. Our services are designed to meeting your needs. We are determined to meet or exceed expectations.

Our team of research development comprised of more 10 highly skilled engineers is dedicated to creating new products that meet market needs offer tailored solutions that meet the specific requirements through constant product improvement research into technology ensure that stay ahead robust conveyor line capabilities offer reliable efficient automation solutions breaking the boundaries of traditional technology leading technological trends This ensures optimal performance for every product develop

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of technological advancements in the field of factory automation. With over a decade of experience, we are specialized in the design, manufacture, and installing a range of automated solutions, including conveyor belts, roller lines, and gantry feeders. We continuously refine our products and come up with new ideas every year to keep up with the changing demands of the market. Our commitment to quality is evident in our ISO, TUV, SGS and ISO certifications, ensuring the highest levels of reliability and performance. When you work with us, it is possible to will receive the best technical support and products designed to enhance effectiveness and quality.

We conveyor line developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.