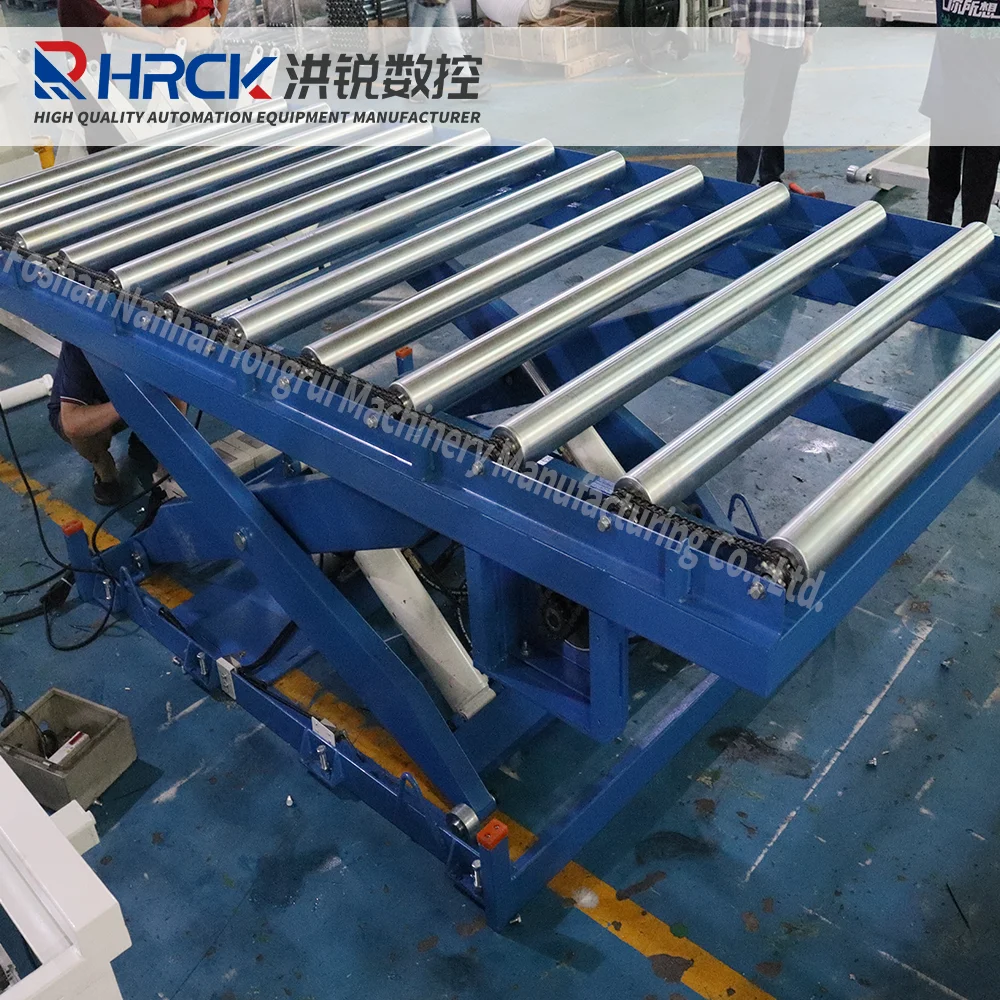

Did you ever ponder how big factories lift heavy items at ease?? Instead, they rely on adjustable roller conveyors. Roller conveyor transfers are useful because they make lift heavy things all the time a lot easier. These work by carrying heavy objects and elegantly lifting them up-down in a specific place as well side to other. This is critical for factories as it spares time and vitality. By automating this work, it enables the humans to focus on another daily important task. Meaning all can work better together!

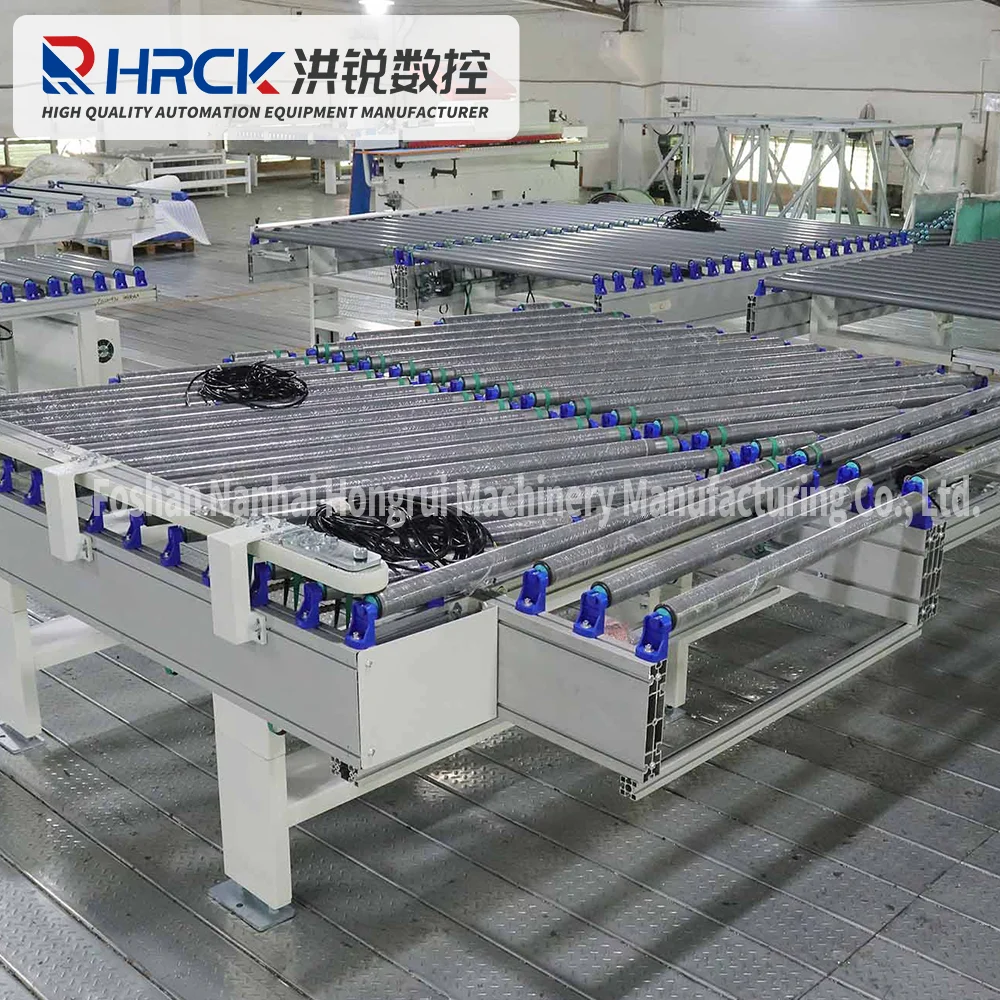

An ensemble of roller conveyors is an incredible machine that assists in the easy movement of materials across warehouses and industries. These have sum small rollers into the track with which they help in pushing of products along a specific path. Sound is quite tough to fancy however imagine a box slide! Roller conveyors typically fall into two categories: powered and gravity. Powered roller conveyors are similar in they move the materials along, but these require electricity to work so that it has sufficient power to get them placed where they need. However, gravity roller conveyors are a non-powered system. Materials within the containers do not move with it, other than to slide along a conveyor path based on their own weight. That makes them so helpful in any type of occasion!

Top things that should be installed in a factory, must carry out by Conveyor systems! Roller systems: These are one of the most functional sorts of finishing remedies readily available, and thanks to roller conveyors every person can do also tough jobs with even more grace. Roller conveyors are used to transport materials from location to another with minimum use of energy. They operate on a chassis of base rollers that transport objects upon the track. Yes — this track is often constructed from durable materials like steel or plastic. The rollers spin and move which pushes the materials or product to where they should be. Conveyor platforms allow factories to cut costs as it will require workers less time and energy when transporting those big items.

Because gravity roller conveyors help simplify operations and add speed for manufactures, many factories are using them more frequently. Among the major benefits they offer is that of enhanced workplace safety. After all, the more products which go out of their camping at a faster rate can happen with less physical lifting ordering to be done by employees. This is a great way to avoid injuries for people who work. One of the biggest benefits of roller conveyor transfers is that they can make material moving fast and efficient. The use of these systems means that factories can carry out transportation in a significantly reduced time span devised, and hence allow for more goods to be possibly transported / (produced)! Roller conveyor transfers, lastly come in a wide assortment of shapes and sizes. This makes it customizable depending on the requirements of a particular factory making it even more beneficial.

If getting heavy parts in the variations from one destination to another is a goal, roller conveyors are sometimes first solution recommended. These are just ideal for conveying heavy or large items from one place to another. Roller conveyors mean no more lifting of heavy items this will help to reduce injuries. These conveyors are also capable of being designed to accommodate the unique layout needs of a single or multi-story building. This makes them perfect for just about any sort of manufacturing or industrial environment. Roller conveyors are a way for everyone to work better at anything that means moving heavy and bulky items in weighty amounts from one place t another!

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the roller conveyor transfer of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

Our extensive after-sales assistance includes installation of the system commissioning it and maintaining Our expert service team is quick to resolve any issues that may roller conveyor transfer while operating With a global network of support and a rapid response time to tech support and solutions no matter where you are We are committed to providing professional and efficient service that will ensure the long-term reliability of your equipment This improves efficiency in production and ensure satisfaction for customers We are attentive to your needs and work to exceed your expectations with every service that we offer

roller conveyor transfer 10 engineers collaborate to create products that align market requirements With continuous technological research product enhancements provide customized solutions tailored to specific client requirements Our strong RD capabilities not only advance technology but also keep leading position in the marketplace offer reliable efficient automation solutions breaking the boundaries of traditional technology cutting-edge technological trends This guarantees optimal performance for each product develop

In Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have built substantial expertise in the woodworking industry. Since our beginnings we've been a leader in offering customized automation solutions, tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well understanding of the specific challenges and requirements of woodworking production. With years of experience in the industry, we design and provide efficient, reliable automation systems which improve efficiency of production and product quality. We don't just assist clients to enhance their processes but we also address many specific industry issues. Every system is compatible with the requirements of woodworking. Work with us to receive an roller conveyor transfer assistance within the woodworking industry and give your production line an edge over competitors.