HRCK is a concept that quickly and smartly creates really nice wooden doors. They produce beautiful doors, tailored specifically for their customers using both specialized machinery and local labor. With the combination of isi technology and artistry, they are able to manufacture beautiful, strong and durable doors.

HRCK enables people to write their own ticket and get the wood doors they want without ceremony. First, you choose what type of wood you’d like, such as oak or walnut. Oak is fair known as being tough, and walnut is dark and something many adore. After deciding which wood suits your need, the next step is to cut it into the appropriate size and shape for your door. With this, you are using machines that make exact cuts. The artisans then leverage their expertise to handcraft each door, ensuring everything is just right. They can apply special designs or carvings that represent each customer’s style and taste. And finally, the door receives its color or finish — a stain that highlights the wood’s natural beauty or a paint color that complements the house. Finally, it is inspected for quality standards so that a good quality door reaches your hand.

There are many steps to the production of HRCKs wood door which work together to create the final product. It begins with preprocessed, larger pieces of wood known as lumbar, which is cut into appropriately-sized pieces with specific, purpose-built machines. The high-tech devices ensure the cuts are straight and clean. After the wood is cut, it is handed to skilled workers to sand and carve it into the appropriate shape. This makes the wood smooth, and sometimes carving gives a specific design which makes the doors unique. From there, the customer’s desired paint or stain is applied to the doors. The workers must be careful to make sure color is applied evenly. The final step is to test the quality of every single door to ensure it is nothing less than perfect before dispatch. All of this meticulous checking ensures that mistakes are spotted and every door is ready to be enjoyed.

HRCK has machines to produce wooden doors quicker and more precisely. Machines do a great deal of the hard work, which enables the skilled workers to focus on the beauty and details of the design by hand. This matters because machines are great at cutting and shaping, but a skilled worker’s touch gives character to every door. That combination of machinery and manual labour ensures that the doors are constructed to the highest standards, and they also look amazing too. Technology has allowed HRCK to make our doors faster, and thanks to that, our customers get their doors earlier without giving up on the quality.

They pay careful attention to all aspects of the door making process at HRCK. Taking each step with care is how they ensure that the doors are the best they can get. From selecting the right wood to finishing the door to perfection, every step is performed with pride by craftsmen honed from generations of practice. They know that every door matters to that customer and they do their very best to build it right. Each door is inspected to ensure it is crafted carefully to meet the company’s high standards. It’s meticulous avoidance like this that sets HRCK’s doors apart from its competition.

More 10 engineers collaborate to wood door production line innovative products that are in line market requirements offer tailored solutions to meet client dem s through continual product improvement research into technology maintain a competitive edge robust RD capabilities offer reliable efficient automation solutions that push the limits of traditional technology advancing technological trends This ensures the highest performance for each product design develop

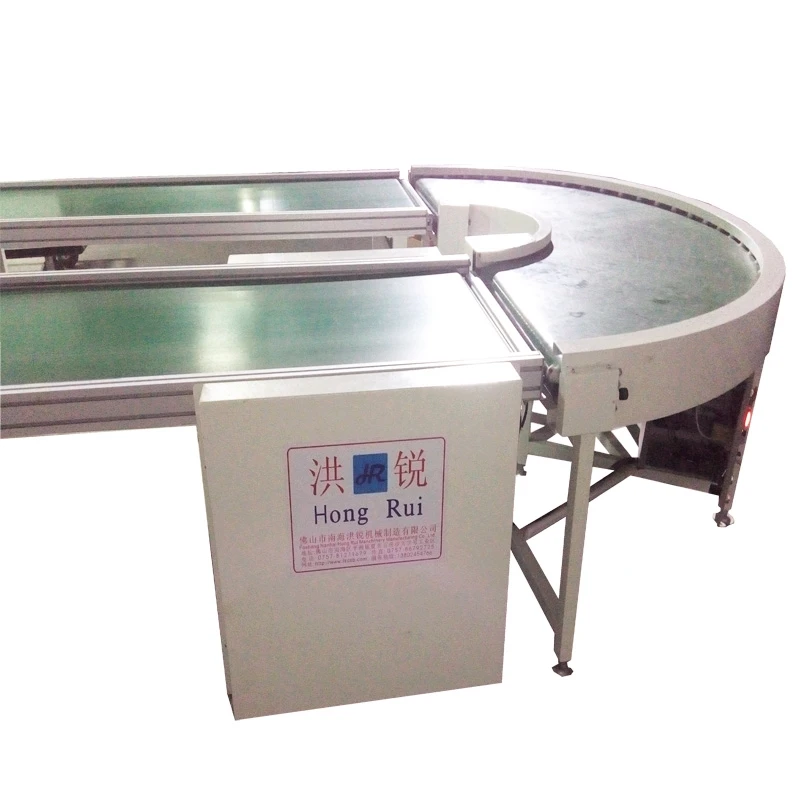

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed a vast expertise in the woodworking sector. Since our inception we've focused on delivering customized automation solutions tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well-versed in the challenges and requirements of production in woodworking. wood door production line years of experience in the field we develop and offer effective, reliable automation systems that increase efficiency in production as well as product quality. We not only help clients improve production processes, but also solve industry-specific challenges. Each system is aligned with woodworking requirements. Our woodworking experts can give your production line an edge with our expert support.

Our extensive after-sales assistance includes installation, commissioning, and maintenance. Our customer service staff is highly educated and is wood door production line to respond to any problems that may occur. With our global support network We provide prompt technical support and solutions no matter where you are. We're committed to providing professional and efficient service that ensures long-term reliability of your equipment. This will enhance efficiency in production and ensure satisfaction for customers. We take your requirements into consideration and aim to meet your expectations with each service we offer.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of manufacturing automation for more than a decade. With over a decade's experience, we have a specialization in designing, manufacturing, and constructing a broad range of automated solutions, including conveyor belts, roller lines, and gantry feeders. We continuously refine our products and introduce innovative solutions annually to keep up with the changing demands of the market. Our ISO, TUV and SGS certifications demonstrate our commitment to quality and ensures the highest standards of reliability and performance. Our customers will benefit from high-end technology and products that wood door production line efficiency and quality.