We have a specialized factory that produces wood panel loaders at HRCK. While performing routine jobs, these loaders are really powerful machines that make life simpler for the workers. We are a new factory and make use of the most up-to-date technology which allows us to work faster, and more efficiently. We have some automatic machines that help to build timber panel loaders in a shorter time. That means we can create more loaders and support more workers.

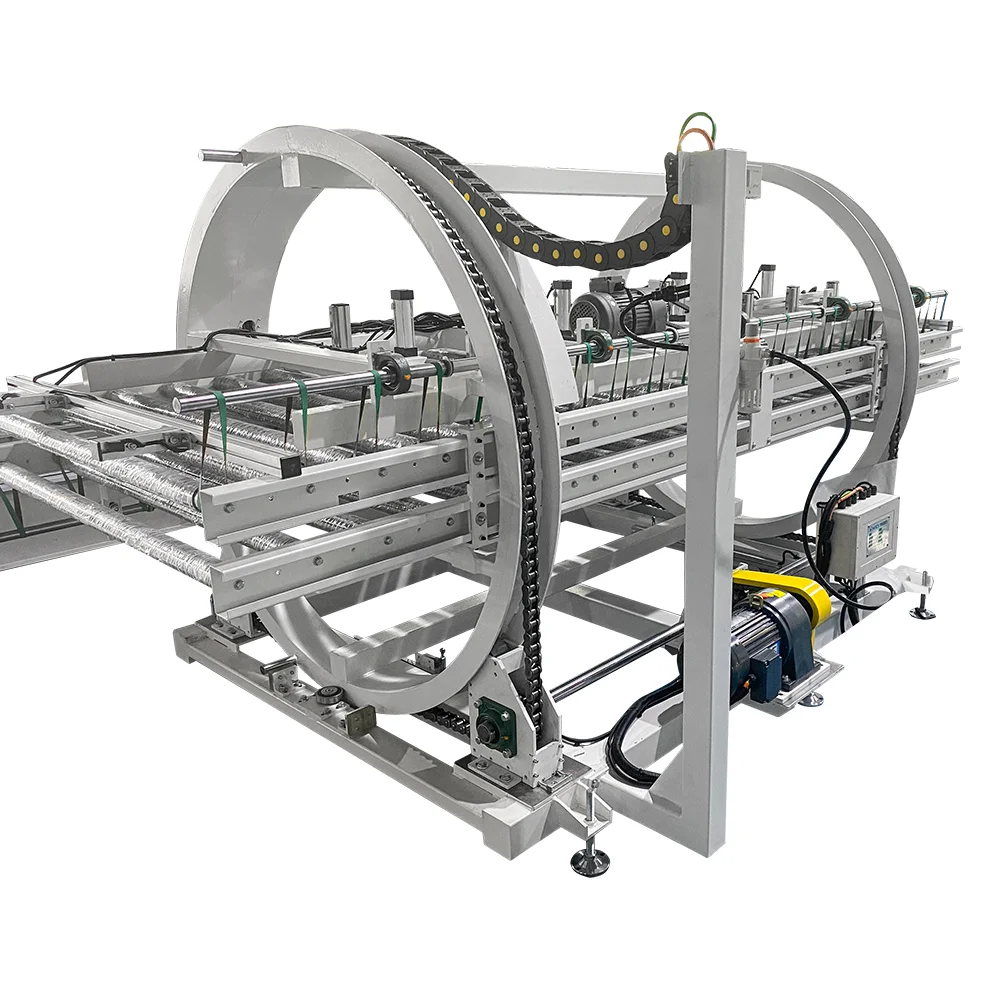

At the HRCK factory, there orders are received to make wood panel loaders. We utilize superior and tough materials that are capable of supporting heavy wood panels without shattering. We first collect these raw materials and then we cut them into precise measurements using machines. The wood panel loader consists of several parts made from thin sheets that are cut and bent. All of these parts are important, as they work together to allow the loader to work.

At HRCK we hold a firm belief that Quality matters a lot. This is the reason why we have a very special team called quality control team. Their job is to test every wood panel loader we create for accuracy and proper implementation. They definitely take the time to go over every component of the loader. They look for errors and also verify that the loaders meet safety standards. In this way, we will feel that our wooden panel loaders are safe and reliable for the workers who use them.

We operate out of a large building with plenty of room. The inside has all the big machines that actually make the wood panel loaders. These machines are very advanced and controlled by skilled technicians. The technicians check that all is well and that the machines are working. With all those machines in one place, it can get a little loud. Due to the excessive noise, we give our workers ear muffs and hearing protection.

The factory itself runs 24 hours a day. There is a lot of workers coming into the factory at different times. Others work nights, and some come in the day. In the factory, each worker has a different job. Some workers cut the materials to size, and others bend and form them. The various components are then brought together by workers to produce the actual wood panel loaders. It is through this collaboration that we manage to meet the demand for our products.

We have wood panel loader factory up a significant amount of experience in the woodworking industry within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of satisfying their specific needs. Our team is familiar with the demands and challenges of production woodworking. With years of experience in the industry, we design and provide efficient, reliable automation solutions which improve efficiency of production and product quality. Our specialized knowledge assists clients in optimizing their processes, but also tackles many technical issues that are specific to industry making sure that each system is perfectly aligned with the needs of woodworking. Our woodworking specialists can help your production line gain an edge through our professional assistance.

More 10 engineers collaborate to develop innovative products that keep up market dem s provide customized solutions that meet the specific requirements continuously improving products research into technology Our strong RD capabilities not only advance technology but also keep edge in the market deliver efficient reliable automation solutions that break the boundaries of traditional technology leading wood panel loader factory trends This ensures the highest performance for every product create

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of factory wood panel loader factory technology for over 10 years. With more than a decade of expertise, we specialize in creating, manufacturing and constructing a broad range of automation options, including belt conveyors as well as roller lines and gantry feeders. Our products are continuously improved and we come up with new solutions every year to keep up with changing demands of the market. Our ISO, TUV and SGS certificates reflect our dedication to quality and ensures the highest standards of quality and reliability. You will benefit from our top-notch technology and products which maximize efficiency and quality.

Our extensive after-sales assistance includes installation, commissioning, and maintenance. Our customer service staff is highly educated and is wood panel loader factory to respond to any problems that may occur. With our global support network We provide prompt technical support and solutions no matter where you are. We're committed to providing professional and efficient service that ensures long-term reliability of your equipment. This will enhance efficiency in production and ensure satisfaction for customers. We take your requirements into consideration and aim to meet your expectations with each service we offer.