Have you ever wondered how the furniture in your home is crafted? It’s really interesting! Now let’s get to the inside of HRCK’s factory, where they produce something called — panel furniture. Many households have this furniture, and this comes with various designs. You will be able to see them create this furniture and learn about all the various things they can do. HRCK uses old-school talent, augmented by new tech, to make the latest in key people we love.

When we enter the HRCK factory, we are immediately aware of the sounds that surround us. We hear machines slicing and shaping pieces of wood. It smells really nice with all the fresh wood. We see piles of wood waiting to be made into beautiful furniture. Well, the factory is quite an enormous place, and definitely larger than a classroom, and there are many different machines that are working together to produce various nice and useful furniture pieces.

To start with, manufacturers decide how their furniture will look like. You will find stronger woods such as oak, maple, and walnut in their top products as they are strong and look great as well. Once they agree on the design, and the wood, the next step is to slice the wood into the proper sizes. They have special machines that make very precise cuts to ensure that each piece of wood is the correct size.

After cutting, the workers sand and smooth the piece to prepare for the next step. This is important because it makes the wood more or less safe to touch and gives it a nice finish. The next step, after sanding the wood pieces smooth, is to compress them together with glue. They use special machines to press the pieces of wood with heat so they can glue it together. Which means the pieces will bond tightly and be strong.

The bonded wood is then re-cut to the precise size and fit for each piece of furniture. It is done with precision in order to ensure proper fit. Then they sheathe the wood with a layer of veneer or paint. It gives a burst of color and adds beauty to the furniture. And finally in the last step you will combine all the parts. They employ traditional methods of carpentry that have been in practice for several years. You are doing this to create the final piece of furniture so it is a very crucial part of the step.

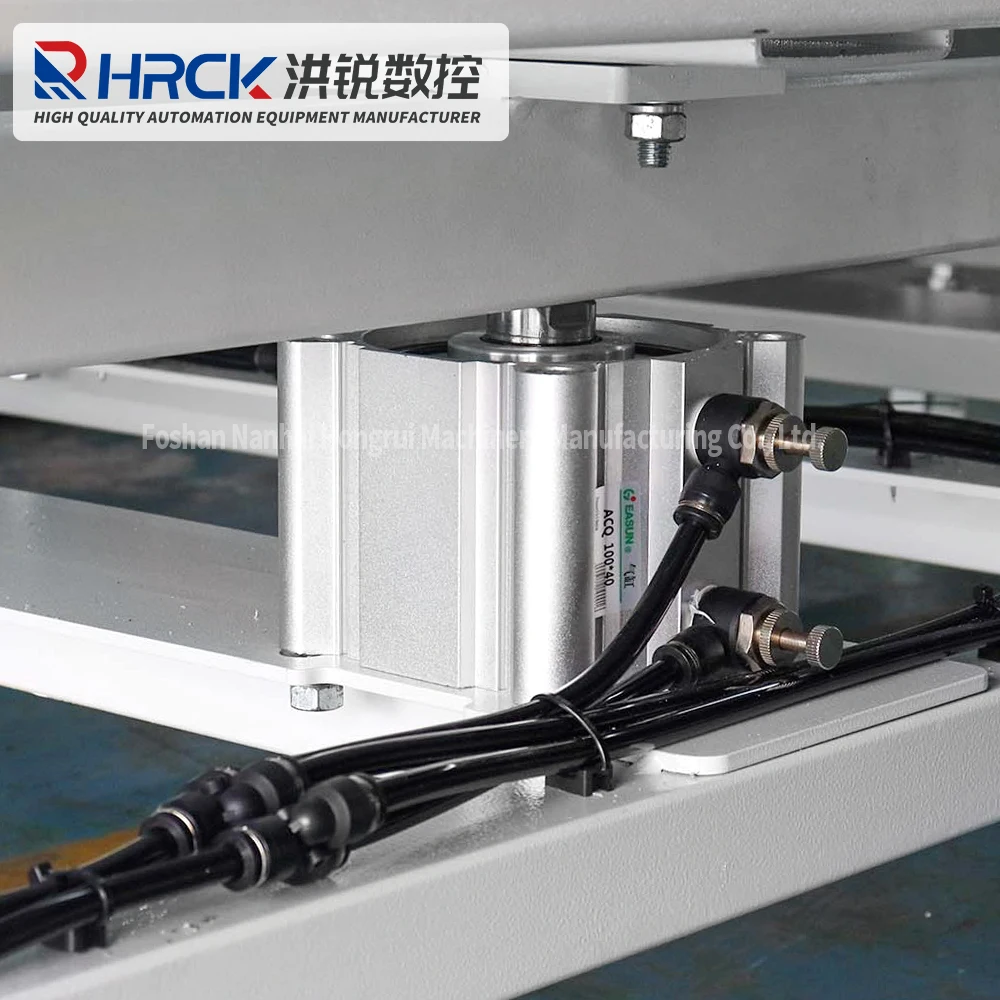

HRCK's workshop is designed for efficiency and optimal furniture quality. This means that they want to get the project completed quickly but at the same time they also want to ensure that each piece they make is extremely high quality. They do this using new tools and new technology. Computers assist the machines in cutting, shaping and bonding the wood, making a faster and more accurate process overall. Machines quickly and precisely adjust to ensure each piece is perfect.

HRCK believes in combining traditional techniques with new technology to create furniture that in turn will last for years. The skilled workers, also referred to as craftsmen, work with modern machinery to produce attractive and highly functional furniture. They assemble the furniture using old-world woodworking methods. This is significant as it provides the furniture with a unique essence and texture that individuals love.

We provide a wide range of after-sales services that include installation commissioning as well as maintenance Our service staff is experienced and responds swiftly to address any issues that may arise during operation With a global support network We provide panel furniture production line factory support and solutions no wherever you are We're committed to providing efficient and professional support that guarantees the reliability of your equipment This will enhance production efficiency and customer satisfaction We are attentive to your needs and work to exceed your expectations with every service that we provide

At panel furniture production line factory we have developed an extensive knowledge in the field of woodworking. We've provided custom automation solutions for woodworking operations since the day we started. From conveyor systems to processing equipment, we are experts in understanding their particular requirements. Our team has a deep knowledge of the particular challenges and requirements of woodworking production. We create and implement efficient and reliable automation systems that improve production efficiency and the quality of products. Our specialized knowledge not only helps clients optimize their processes, but also tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Join us for assistance in the woodworking sector to give your production line a competitive edge.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the panel furniture production line factory of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

Our research development team consisting of over 10 highly skilled engineers is committed to developing innovative products that meet market needs With continuous technological research enhancements to products provide customized solutions that are tailored to the specific needs of clients specifications Our robust RD capabilities don't just improve technology but also keep leading position in the marketplace deliver reliable efficient automation solutions breaking the limits of traditional technology cutting-edge technological trends This ensures panel furniture production line factory of every product develop