We at HRCK are excited to present our latest and newly innovated mdf panel production line by HRCK. What is MDF? MDF stands for medium-density fiberboard. This is a comparatively newer type among the wood boards and is made from small pieces of wood MDF (medium-density fibreboard) is a popular choice for many people and used in the construction of furniture, flooring areas as well as buildings. We start with wood chips, break them down into small fibers and add a sticky substance called resin to form mdf machinery production line. When you make this process, they are solid and thick boards that serve a multitude of purposes.

So, this is how we make really nice mdf panel production line by HRCK very quickly. Because we understand that each customer has specific requirements, it is possible to modify them for the MDFpanel furniture product line. The boards can be made as thick, wide and heavy that you like. That allows you to find just what is required for your project.

MDF is a its an amazing material to make furniture of because it has near about no grain, and therefore easy yo work with. What this means is that it has the same gauge and weight from top to bottom, ultimately allowing for a simpler installation process. And MDF panel furniture production line is cheaper than wood, and this saves money. We employ a team of professional craftsmen who design our mdf panel production line from HRCK with accuracy, ensuring your furniture looks and stays brand new for years to come.

There are a few steps to making mdf panel production line by HRCK. In essence, the way we begin this process is by turning wood chips into tiny fibers. The fiber slurry is then dried so that no moisture remains. Once dry, the fibers are then combined with resin to form an adhesive-like compound. After that blend is formed, we press it into a stiff solid board using huge amount of force and heat. The process which the home furniture production line use to make it gives is extreme strength and strength ready for us.

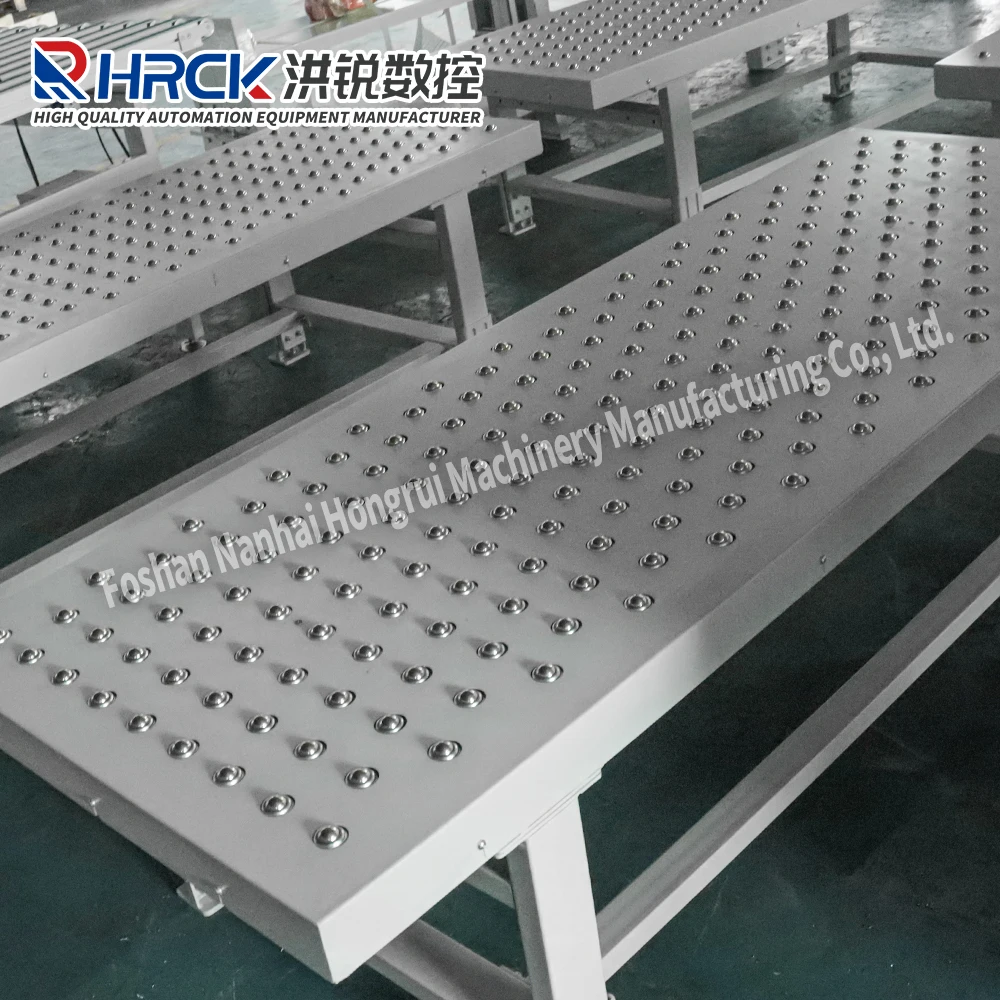

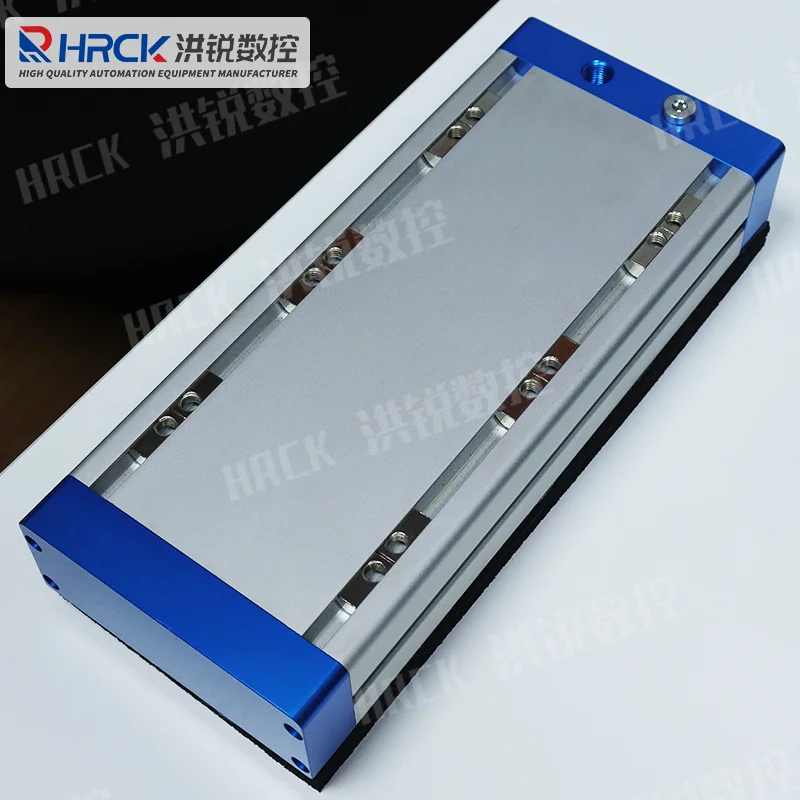

At HRCK, we employ the use of smart machines and top tier technology to streamline making mdf panel production line by HRCK quickly and with utmost precision. This is crucial as wood line maintain the uniformed thickness and weight of the boards from beginning to end. We also posses specific high-end tools and material handling equipment to ultimate strength the manufacturing so that it truly smooth boards there is not a defect on them. Such things make us capable of generating best in class products.

Our research development team composed of over 10 experienced engineers is dedicated to developing new products that are able to meet the needs of the market offer tailored solutions that meet the specific requirements continuously improving products as ll as technological research stay ahead of the competition utilizing strong RD capabilities Through advancing technological trends bending the limits of conventional thinking deliver efficient reliable Mdf panel production line ensuring the highest performance for each product design

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of factory automation technology for over 10 years. With more than a decade's expertise, we specialize in the design, manufacture, and putting in place a variety of automation solutions, such as belt conveyors, roller lines, and gantry feeders. We constantly improve our products and introduce innovative solutions annually in order to meet changing market needs. Our ISO, Mdf panel production line and SGS certifications demonstrate our commitment to quality, which ensures the highest standards in the reliability and performance. Our customers will benefit from top-notch technology and products that improve efficiency and quality.

Mdf panel production line have accumulated a large quantity of expertise in the field of woodworking within Foshan Nanhai Honorgrui Machinery Manufacturing Company Ltd. Since our inception, we have specialized in delivering customized automation solutions tailored to the particular requirements of woodworking processes, including conveyor systems, processing equipment and more. Our team is familiar with the demands and difficulties of woodworking production. We create and implement efficient and efficient automation systems that increase production efficiency and the quality of products. Our knowledge of the industry does not just assist clients to optimize their production processes, but tackles the technical challenges specific to their industry, ensuring that each system is perfectly aligned with the woodworking demands. Partner with us for assistance in the woodworking industry that will give your line of production an edge.

Our Mdf panel production line after-sales support includes installation, commissioning and maintenance. Our expert service team responds promptly to any issues that may arise in the course of operating. We offer a worldwide support network that allows us to provide prompt solutions and technical support, no matter where you may be. Our commitment to prompt and professional service ensures the long-term, stable operation of your equipment, improving efficiency and satisfaction of customers. Our services are geared towards fulfilling your requirements. We are determined to meet or exceed expectations.