Coming Soon: Ex-Refrigerator Robots on the Move These robots are working to carry boxes and materials back and forth. It is known as an automated conveyor belt, or AGV for short! AGVs are like little self-driving cars that pick up and deliver things without a human driver telling them what to do. Where Are They Used?They are used in many places including warehouses, factories, hospitals, and distribution centers so they have become an essential part of how goods are moved in our world.

AGVs can look all kinds of different ways. Some are small and can move only one box at a time and others are much larger, carrying many boxes or even pallets of products. They have special sensors and cameras that enable them to see what is around them. As they move around, this technology helps them detect and avoid running into walls or objects in their surroundings. Some AGVs even come equipped with robotic arms to pick up and move heavy objects, proving ideal for many tasks humans may not be able to perform safely.

One fun feature about AGVs is that they can run all the time—Day & Night and don’t need to take breaks. It allows them to constantly move cargo, which allows for the quick, continuous movement of the product. In a world that never sleeps, AGVs provide organizations the opportunity to achieve crucial time and cost savings and operate 24/7.

AGVs are also a very precise technology. They can also be programmed to move along particular paths and at specific speeds, which ensures that items are moved safely and on time. That is incredibly important for companies that need to keep their operating efficiently, reducing mistakes and ensuring that everything is entering where it needs to go.

Ways that AGVs Can Increase Work Efficiency Some AGVs, for example, are intended to work in conjunction with automated storage and retrieval systems, commonly shortened to AS/RS. These systems involve machines that can pick pallets of material out of high-storage areas and place them onto ID-guided AGVs, which bring these pallets to their final destination. This process can greatly decrease the labour required to shift materials from voice to the production line thus resulting in the saving of time and a decrease in power.

) Another productivity booster AGV provides is safety improvement in the workplace. By taking away the need for manual workers to move heavy items around, companies can reduce the likelihood of accidents and injuries that might occur during transport. Not only does this keep the workers themselves safe, but it can also save money for the employers in terms of insurance and medical costs related to workplace accidents.

One of the biggest advantages of AGVs is efficiency and productivity. Implementing the use of automated transportation helps businesses with material transportation to cut down the duration for moving goods from place A to B. This results in increased output and improved profits for the business, enabling them to manufacture more in the same period.

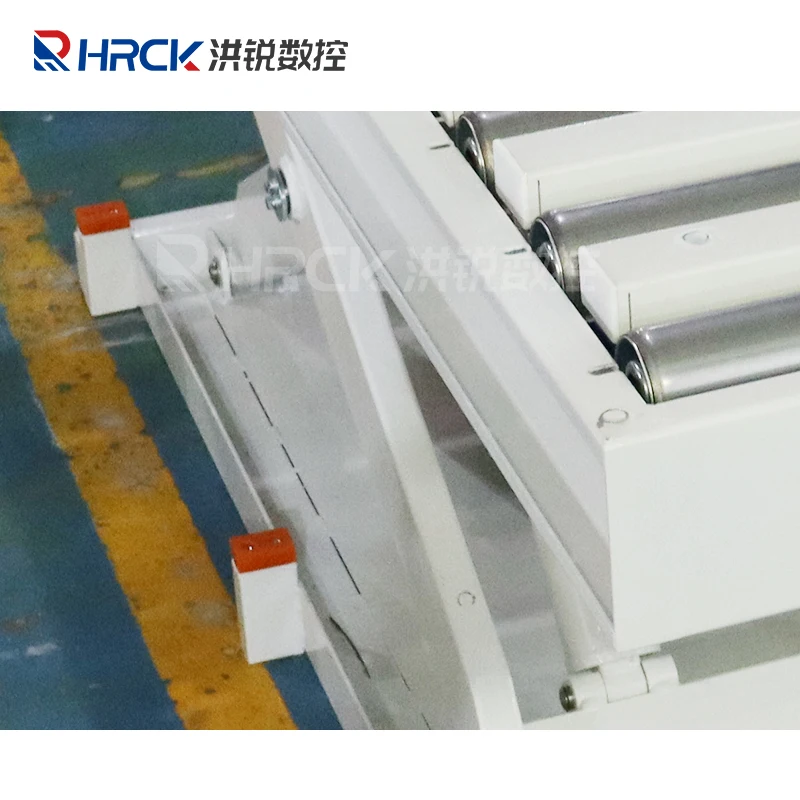

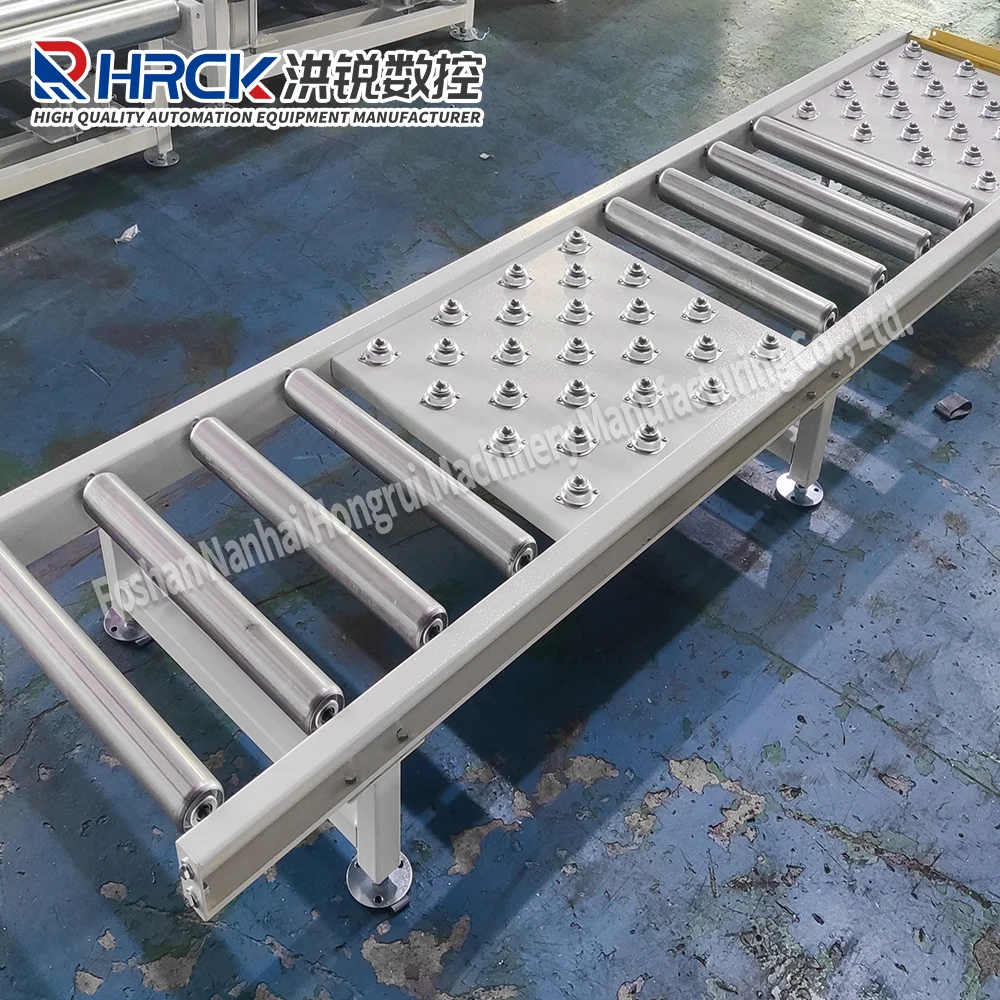

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the automated guided vehicle of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

Over 10 engineers work together to create innovative products that are in automated guided vehicle market Through continuous technological research enhancements to products offer customized solutions tailored to specific client specifications Our robust RD capabilities don't just improve technology but also keep edge in the field With cutting-edge technology breaking traditional boundaries offer efficient reliable automation solutions ensuring optimal performance for every product create

Our extensive after-sales assistance includes installation of the system commissioning it and maintaining Our expert service team is quick to resolve any issues that may automated guided vehicle while operating With a global network of support and a rapid response time to tech support and solutions no matter where you are We are committed to providing professional and efficient service that will ensure the long-term reliability of your equipment This improves efficiency in production and ensure satisfaction for customers We are attentive to your needs and work to exceed your expectations with every service that we offer

We have accumulated a vast amount of experience in the field of automated guided vehicle within Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on offering customized automation solutions, tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team has a thorough understanding of the specific challenges and requirements for woodworking production. Based on years of industry experience, we design and provide efficient, reliable automation solutions that increase efficiency in production as well as product quality. Our expertise does not just assist clients to optimize their production processes, but tackles many technical issues that are specific to industry making sure that each equipment is fully compatible with woodworking needs. Our woodworking experts can help your production line gain an edge by offering expert assistance.