One of those awesome machines is a conveyor belt scrubber, which is one of HRCK’s. It has specialized brushes to scrub the conveyor belt. Since the brushes spin and move around fast, they help clean the belt really well. As the brushes spin round, they scrub off dirt and other unwanted substances which may be adhered to the belt.

It is a thorough clean, meaning that no part of the belt will be dirty. Additional significant advantage is they cleans multiple belt at a time, which reduces worker time. HRCK uses these conveyor belt scrubbers to help keep the conveyor belts as clean as possible so food does not come into contact with anything toxic.

HRCK That is how they have created sanitation systems to ensure the food we eat is safe. These systems operate based on hot water or steam in focus to clean conveyor belts. The hot water or steam is so good at killing any germs or nasty bacteria that may be on the belt.

Sanitation systems are particularly important in venues where high volumes of food are handled. In these factories, conveyor belts if not cleaned properly can become a hotbed of germs. This can cause food to spoil, and can make people sick. HRCK uses these sanitation systems to prevent the risk of germs, ensuring that their food reaches consumers' mouths free from disease.

In food factories, the risk of contamination can be exceedingly high. When a conveyor belt is poorly cleaned, and this allows germs and harmful bacteria to proliferate. This is dangerous for consumers because it can contaminate the food being produced.” That is the reason why it is so important to have HRCK's advanced cleaning machine.

They use technology that incorporates a combination of scrubbers, sanitation systems and other technologies to keep their conveyor belts clean and free of bacteria. This makes it extremely effective, and has been shown to lower the possibility for contamination in a food processing plant. Through the use of HRCK’s cleaning technology, factories can uphold high levels of hygiene and safety, both of which are fundamental for public health.

To simplify this process, HRCK has created automated cleaning solutions. These gadgets rely on sensors and other technology to automatically detect when belts require cleaning. The process happens automatically when it’s time for a cleaning which saves a lot of time and effort for workers. So workers have more time to do other, more pressing jobs rather than spending all their time cleaning the belts.

Our extensive after-sales assistance includes installation commissioning and maintenance Our expert service team is quick to resolve any issues that arise during the course of operation With a conveyor belt cleaning system network we offer timely tech support and solutions no wherever you are Our dedication to dependable and prompt service guarantees long-term and stable operation of your equipment This will increase production effectiveness and customer satisfaction Our services are focused on satisfying your requirements We aim to exceed your expectations

Our team of research development comprised of more 10 highly skilled engineers is dedicated to creating new products that meet market needs offer tailored solutions that meet the specific requirements through constant product improvement research into technology ensure that stay ahead robust conveyor belt cleaning system capabilities offer reliable efficient automation solutions breaking the boundaries of traditional technology leading technological trends This ensures optimal performance for every product develop

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed a vast expertise in the woodworking sector. Since our inception we've focused on delivering customized automation solutions tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well-versed in the challenges and requirements of production in woodworking. conveyor belt cleaning system years of experience in the field we develop and offer effective, reliable automation systems that increase efficiency in production as well as product quality. We not only help clients improve production processes, but also solve industry-specific challenges. Each system is aligned with woodworking requirements. Our woodworking experts can give your production line an edge with our expert support.

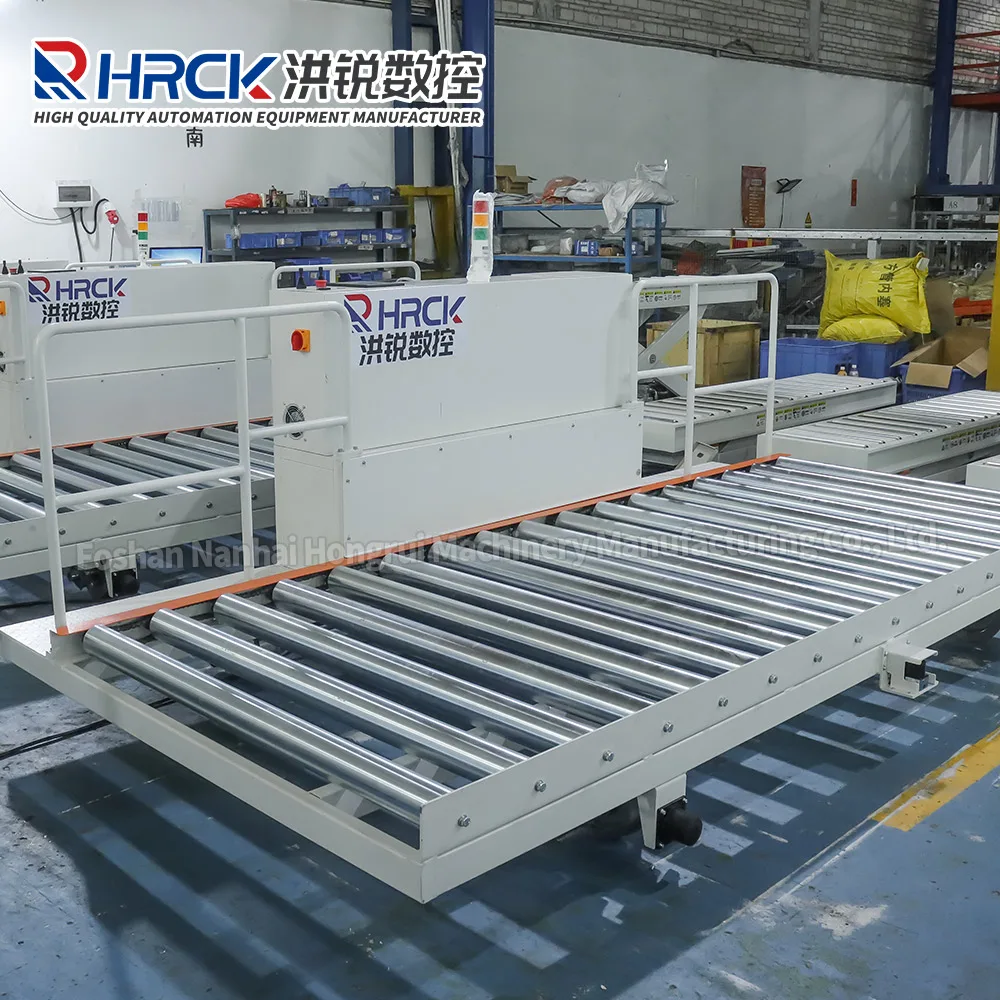

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is a leader in manufacturing automation technology. We have over 10 years of expertise designing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are continually upgraded and we introduce new solutions each year to keep pace with the changing market needs. Our ISO, TUV and SGS certificates reflect our dedication to quality, which ensures the highest standards of reliability and conveyor belt cleaning system. We offer high-end products and technology that optimize efficiency and quality.