These factories move massive amounts of products from point A to point B and you didn’t even think about it. They employ some nifty devices — belt conveyors! Moving them around becomes significantly easier and faster as these systems move items along a defined route. The industrial belt conveyor is robust with little maintenance required, this not only saves time for companies, but in the long run this also saves money.

In an extensive industry that has many goods to move, belt conveyors are effective. Think of a factory that produces toys or clothing. When you start moving you need to transfer many goods from one place to another. A belt conveyor can move things over long distances without a lot of human assistance. It saves a ton of time and minimizes the amount of manual work people have to do. It is built to accommodate both bulky and lightweight items, making it adaptable and reliable for a variety of items.

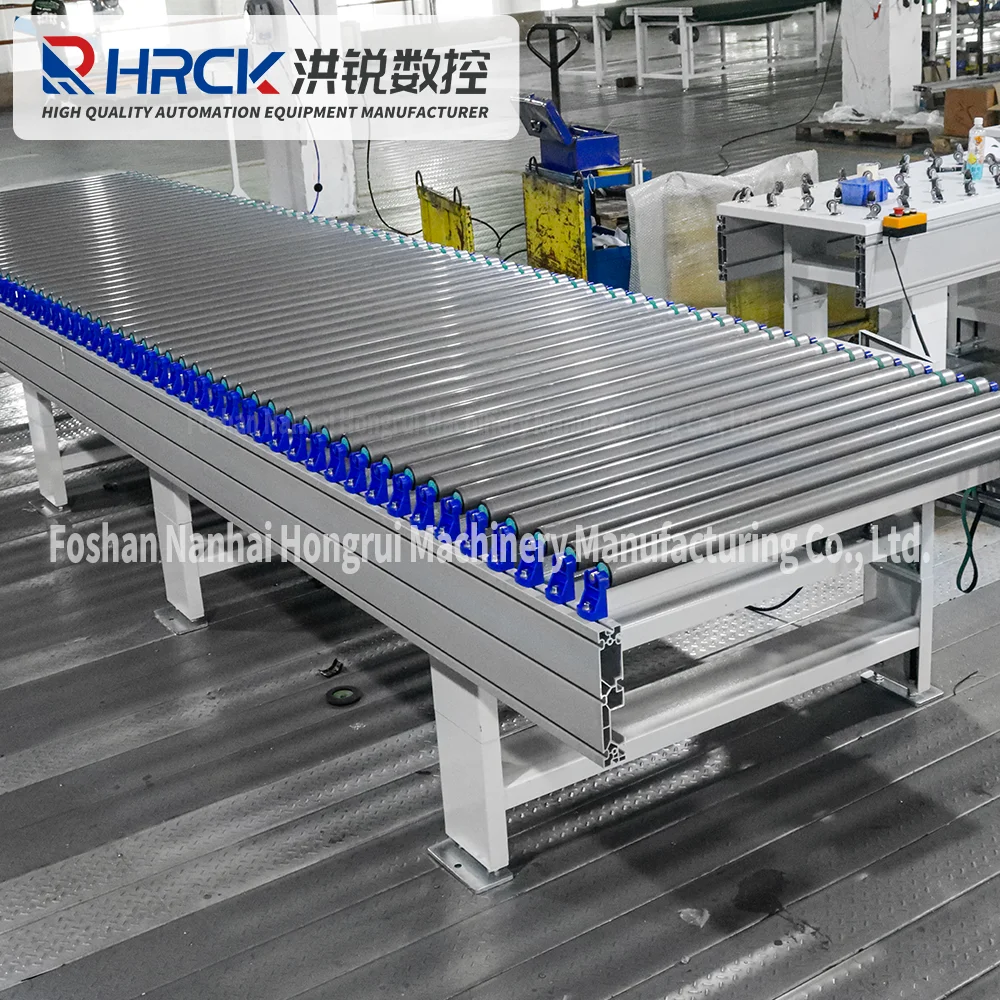

Belt conveyors are stellar because they move heavy things with so little energy. This is a tremendous boon for warehouse workers. Instead of lugging heavy stuff around all day, workers are able to devote additional energy to things like improving the bottom line. HRCK side belt conveyors can also be easily tailored to fit any size of warehouse. It means that businesses can acquire a trusted machine that saves them news time, space and pennies.

In food and drink industry the conveyor system plays a special role in health and safety regulations where cleanability of a conveyor system is very important. HRCK carries out a simple system for cleaning a belt conveyor — all to keep everything so hygienic. In contrast, medicine demands machines that can never be contaminated. HRCK's conveyor system is designed to meet these stringent requirements. These conveyors have flexible design so, every industry can have a breakdown-free, efficient and safe system as per their need.

Mining is an example of an industry such environment can be very dangerous. Belt conveyors can carry mining materials instead of workers lifting heavy materials by hand. It also helps minimise accidents and allows workers to concentrate on other tasks. Belt conveyor system its design contains strength and safety which guarantee the safety. This clever design saves money and time and protects workers’ health and safety as they perform their jobs.

Eco-friendliness is recognized as an essential virtue by all in the world today. How many companies can you say that they are adopting green solutions to lessen their environmental footprint. However, since they also enable businesses to function in an environmentally friendly manner, belt conveyors are very much an eco-friendly option for transporting materials.

By reducing the need for human labour, which generally consumes higher energy, the belt conveyor system helps in minimising the company’s carbon footprint. By utilizing these machines, businesses can also produce less waste and reduce their energy use. Read more - HRCK belt conveyor system not only aids in allowing companies be efficient but also helps in green practices that are good for the earth.

We provide a wide range of after-sales services that include installation commissioning as well as maintenance Our service staff is experienced and responds swiftly to address any issues that may arise during operation With a global support network We provide belt conveyor system support and solutions no wherever you are We're committed to providing efficient and professional support that guarantees the reliability of your equipment This will enhance production efficiency and customer satisfaction We are attentive to your needs and work to exceed your expectations with every service that we provide

We have accumulated a vast amount of knowledge in the woodworking sector at Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on providing customized automation solutions that are tailored to the particular requirements of woodworking, ranging from conveyor systems to processing equipment. Our team is well-versed in the challenges and needs of production woodworking. With years of experience in the industry We design and develop effective, reliable automation systems that enhance production efficiency and the quality of products. Our knowledge of the industry will not only help our clients improve their belt conveyor system, but addresses many industry-specific technical challenges and ensures that every equipment is fully compatible with woodworking needs. Our woodworking experts will provide your production line with an edge with our expert support.

Over 10 engineers work together to create innovative products that are in belt conveyor system market Through continuous technological research enhancements to products offer customized solutions tailored to specific client specifications Our robust RD capabilities don't just improve technology but also keep edge in the field With cutting-edge technology breaking traditional boundaries offer efficient reliable automation solutions ensuring optimal performance for every product create

belt conveyor system has been at the forefront of manufacturing automation for more than 10 years. We have over 10 years of expertise developing, manufacturing and installing systems for automation, including roller lines and belt conveyors. Our products are constantly refined and come up with new ideas every year to meet the ever-changing needs of our customers. Our commitment to quality is evident in our ISO, TUV, SGS, and ISO certifications. They guarantee the highest standards of quality and performance. When you work with us, it is possible to get top-quality technological support and products specifically designed to enhance efficiency and quality.