A band edg conveyor is a type of machine component used in order to move material from one place to another. These are round tubes that rotate and support the weight of the items being transported. They are of varying chunk and build, so its excellent for multitudes of careers. Such conveyor rollers may be found in factories, warehouses, or airports where heavy items must be moved quickly, safely and with the least amount of human effort.

They are very useful for material transportation. They are included in a wide range of industries such as factories that manufacture the products, mines that extract minerals, and transportation services that transport goods. The blocks are crucial in ensuring the smooth movement of heavy objects. They reduce friction, the resistance that makes things hard to slide. Items can move easier and faster along the conveyor system because the rollers aid in dampening this friction. With the right conveyor roller, it ensures everything runs seamlessly without damaging or getting stuck.

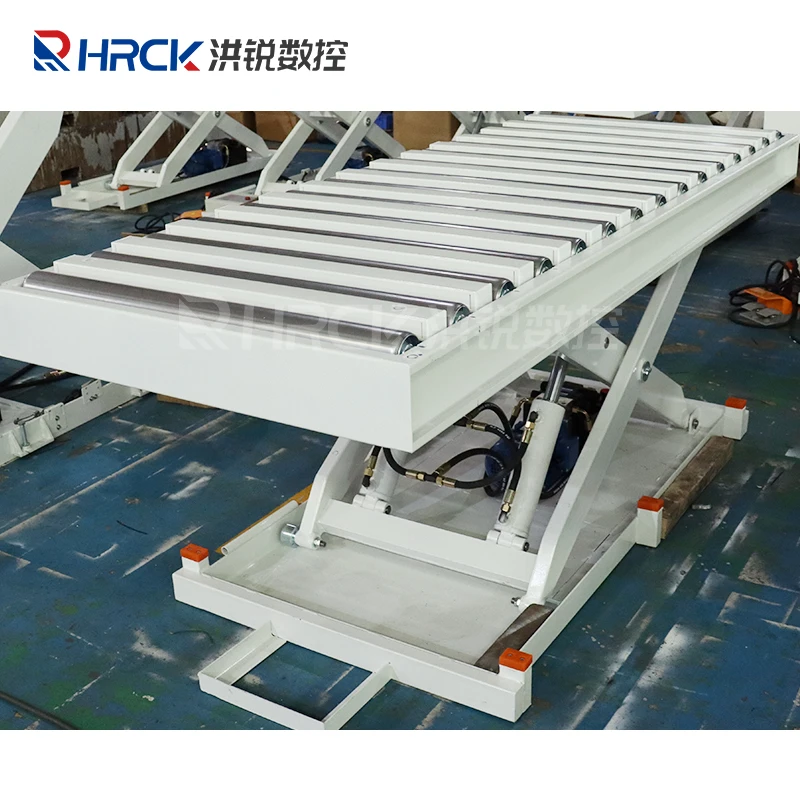

Choosing the right adjustable roller conveyor for your business can be difficult. HRCK offers a wide variety of conveyor rollers with different materials plastic, stainless steel, and carbon steel. Each type has unique characteristics that make it suitable for different tasks. Plastic rollers are lightweight and rust resistant, and stainless steel rollers are very strong and capable of handling heavy loads, for example. When selecting a roller, consider how much weight it must bear, how fast it must go and where it will be used. Keeping these aspects in mindwill help you to hit the right roller for your requirements.

Conveyor rollars will require proper maintenance to make them long lasting. They're also useful to keep them clear so dirt doesn't accumulate and inhibit them. If dirt build up on the rollers, it could lead to higher wear and tear and the rollers not working as effectively. By regularly adding oil or lubricant, the rollers can move smoothly and do not get stuck. It is also very important to check the rollers for damage. If you detect potential problems early, you can address them before they snowball. HRCK can help with maintenance to keep the rollers running well and to make sure everything is safely operating.

While there is a lot that has been said about conveyor rollers, let us look at how new designs have changed the way materials are moving in several industries. HRCK has developed various rollers, such as gravity rollers, powered rollers, and tapered rollers. Gravity rollers enable items to roll freely down an incline, a feature that’s handy when you want your materials to flow without requiring power. However, powered rollers can transport items on their own, which is helpful to keep things moving as fast as possible without someone behind the device. This design keeps materials from falling off the conveyor as they are being transported, making the operation much safer for you and your co-workers.

Transport roller systems (conveyor roller systems) ensure safety in operation and time savings for everyone. American Changer's conveyor rollers are made with safety features to reduce the risk of workplace accidents. For instance, tapered rollers prevent materials from being able to fall off the conveyor (and injure workers). Some rollers mount to a sturdy frame that offers additional protection for workers in close proximity. This type of systems also expedite work by automatically moving needed materials, minimizing human input in heavy lifting. When workers don’t need to lift heavy loads manually themselves, they can concentrate on other important work.

Our research development team consisting of over 10 highly skilled engineers is committed to developing innovative products that meet market needs With continuous technological research enhancements to products provide customized solutions that are tailored to the specific needs of clients specifications Our robust RD capabilities don't just improve technology but also keep leading position in the marketplace deliver reliable efficient automation solutions breaking the limits of traditional technology cutting-edge technological trends This ensures conveyor roller of every product develop

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the forefront of factory automation technology for over 10 years. With more than a decade's expertise, we specialize in the design, manufacture, and putting in place a variety of automation solutions, such as belt conveyors, roller lines, and gantry feeders. We constantly improve our products and introduce innovative solutions annually in order to meet changing market needs. Our ISO, conveyor roller and SGS certifications demonstrate our commitment to quality, which ensures the highest standards in the reliability and performance. Our customers will benefit from top-notch technology and products that improve efficiency and quality.

We have accumulated a vast amount of experience in the field of conveyor roller within Foshan Nanhai Honorgrui Machinery Manufacturing Corporation, Ltd. Since our beginnings we've focused on offering customized automation solutions, tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team has a thorough understanding of the specific challenges and requirements for woodworking production. Based on years of industry experience, we design and provide efficient, reliable automation solutions that increase efficiency in production as well as product quality. Our expertise does not just assist clients to optimize their production processes, but tackles many technical issues that are specific to industry making sure that each equipment is fully compatible with woodworking needs. Our woodworking experts can help your production line gain an edge by offering expert assistance.

The extensive after-sales services we offer include installation as well asconveyor roller and maintenance. Our skilled service team is quick to resolve any issues that arise while operating. We have a global support network, which allows us to offer timely solutions and technical assistance regardless of where you happen to be. Our commitment to speedy and efficient service guarantees the long-term, reliable operation of your equipment, improving the effectiveness of your production and ensuring that you are satisfied with our services. We take your requirements into consideration and strive to exceed expectations with every service that we provide.