We all know that doors are an important part in our houses and areas. They protect us, seclude us and can use to beautify our homes. When is the last time to give any consideration what at doors where made of? Factories use this special process, called the door production line to mass-produce doors quickly and easily. With this, it helps us have the doors for our homes and also workplace.

Once the doors have been sanded, they are put on a conveyor belt for paints. You can get the doors in a multitude of colors and finishes to match what you fancy. Bright-colored: Some would rather dress with bright colors, as others avoid using lots of them. After the paint is sprayed, now we let our doors dry. The drying time is necessary because it makes sure the paint dries properly, thus preventing chipping and scratching easily.

Manufacturers continue to improve their door production lines and increase its speed. HRCK Customized furniture production line is the new technology which has been invented to even fastening and more accurate. An example of such innovation is the utilization of lasers. Lasers are incredibly accurate and get the job done quickly than any man power ever can, saving time while increasing quality simultaneously in creating doors.

Robots are used in the large-scale factories which is another useful tool. Robots can help with painting and sanding, which ultimately reduces the number of employees required to do these jobs. Robots can make the process more consistent, which helps that each door is created equally to rigorous standards. This is the way technology works to speed up operations and also lessen chances of errors by manual workforce.

Once the doors are painted and dry, they then undergo an important quality check. This is done to ensure that each door meets the quality standards for a manufacturer. Inspectors ensure that paint is perfect and door surface are without any bumps, dents or scratches. Obviously HRCK panel furniture production line has to be very precise in their work or the door might not look right and also may not open a shut correctly.

Doors are in demand with versatile specifications for the customers. That's why the HRCK Intelligent production line for wooden doors is so many. Others are completely closed, while doors with small windows within them will allow light to pass through into a room yet still provide some kind of cover. Others have looting devices in them, that makes it more secured to homes and companies.

Doors come in many shapes, sizes and. different types of materials like wood metal or glass etc. There are indoor doors and some that go for the outside. Outside doors are for protection from the elements and must be sturdy while indoor doors provide privacy yet also function as decorative access points. Due to the wide variety of styles at their disposal, customers can now select with pinpoint accuracy exactly what they require in home or building aesthetics.

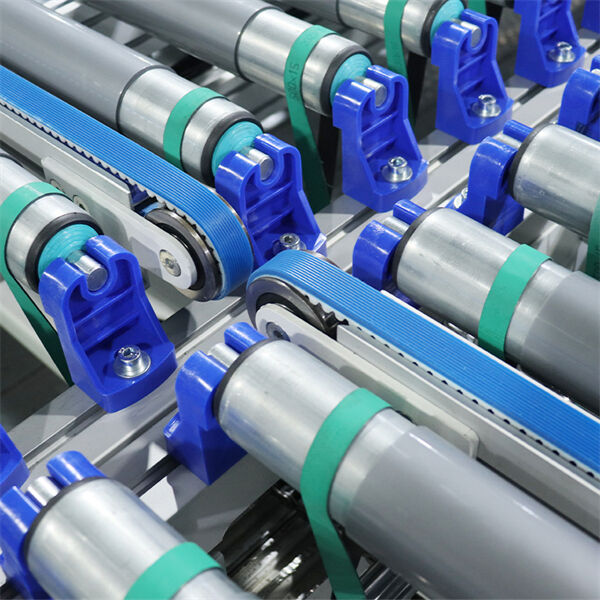

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. has been at the Doors production line of factory automation technology for over a decade. With over a decade's experience, we specialize in creating, manufacturing and putting in place a variety of automation solutions, such as conveyor belts rolling lines, roller conveyors, as well as gantry feeders. We continually improve our products and introduce innovative solutions annually in order to meet changing market needs. Our dedication to quality is evident in our ISO, TUV, SGS, and ISO certifications, which guarantee the highest standards in reliability and performance. If you select us, you receive top-quality technical assistance and products that are designed to optimize both effectiveness and quality.

We Doors production line developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.

More 10 engineers collaborate to Doors production line innovative products that are in line market requirements offer tailored solutions to meet client dem s through continual product improvement research into technology maintain a competitive edge robust RD capabilities offer reliable efficient automation solutions that push the limits of traditional technology advancing technological trends This ensures the highest performance for each product design develop

We provide extensive after-sales services which include Doors production line, commissioning, as well as maintenance. Our team of service technicians is highly educated and is quick to respond to any problems that may arise. We offer a worldwide support network that allows us to offer timely solutions and technical assistance, no matter where you may be. We're committed to providing efficient and professional service that ensures long-term stability of your equipment. This will improve productivity and satisfaction of customers. We are attentive to your needs and work to exceed your expectations with each service we provide.