Have you ever wondered why huge factories and warehouses can move heavy stuff so easily? It's all in something with a name conveyor rollers. All these little gears work together to move packages along a designated route. This is how the handling of materials is faster and easier and keeps the process running smoothly.

Conveyor roller parts are cylindrical structures that attach to a system constructed using belts, chains, or other machines. They are available in different sizes to meet your needs. These parts are basically used to support the weight of the goods being transported and also control their direction along the conveyor.

Bearing is a component that is found at the center of each conveyor roller part. Bearing is a crucial part so that roller can rotate smoothly. It also helps reduce friction as the items roll. In the absence of bearings, the moving parts of the conveyor rollers would wear out in a short time causing huge problems for the entire system.

So, conveyor roller parts use various ways to transport materials in a specific pathway. These include gravity, motor power, or even human assistance. Gravity Assist on a Conveyor (Part 1) When an item is simply placed on the conveyor belt, gravity helps by pulling it down onto the rollers. The rollers then keep and guide the object along the belt.

The rollers in a power conveyor are directly powered using a motor, which drives the drum of the rollers, making them move together. This motor runs the belts or chains, that are used for transporting the things. This type of system is great for moving heavy loads over long distances, or even up hills. It eases the job and helps with rapid transfer of goods.

Conveyor roller part parts are essential elements of any material handling system. Without them, factories and warehouses would be hard pressed to run smoothly. These components help keep everything running like a well-oiled machine — critical when it comes to production and delivery timelines.

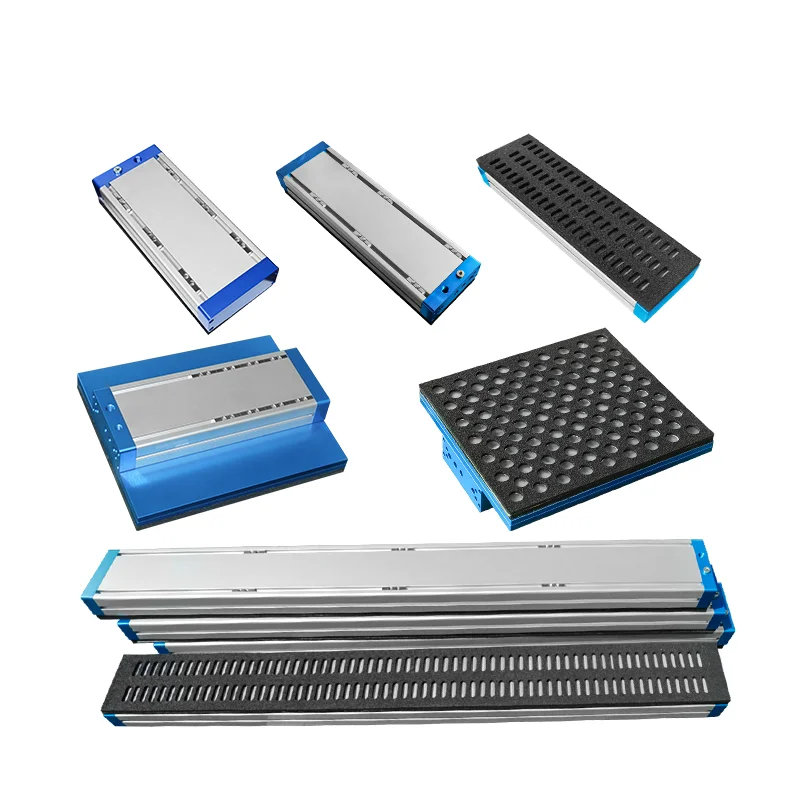

With so many different types of components, they each have a varying specific role to play in the material handling process. That is why at HRCK we provide these components in many diversity allowing our customers to find what they are looking for. Some common types of conveyor roller parts you should know about include:

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of manufacturing automation technology. With over a decade's experience, we have a specialization in developing, manufacturing, and constructing a broad range of automation solutions, including conveyor belts as well as roller lines and gantry feeders. Our products are constantly improved and we launch new products every year to keep up with the ever-changing needs of the market. Our commitment to quality is reflected in our conveyor roller parts, TUV, SGS, and ISO certifications, ensuring the highest standards of quality and performance. You will benefit from our top-of-the-line technology and products that maximize efficiency and high-quality.

We provide extensive after-sales services which include conveyor roller parts, commissioning, as well as maintenance. Our team of service technicians is highly educated and is quick to respond to any problems that may arise. We offer a worldwide support network that allows us to offer timely solutions and technical assistance, no matter where you may be. We're committed to providing efficient and professional service that ensures long-term stability of your equipment. This will improve productivity and satisfaction of customers. We are attentive to your needs and work to exceed your expectations with each service we provide.

At Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd., we have developed a vast expertise in the woodworking sector. Since our inception we've focused on delivering customized automation solutions tailored to the specific requirements of woodworking, ranging including conveyor systems, processing equipment and more. Our team is well-versed in the challenges and requirements of production in woodworking. conveyor roller parts years of experience in the field we develop and offer effective, reliable automation systems that increase efficiency in production as well as product quality. We not only help clients improve production processes, but also solve industry-specific challenges. Each system is aligned with woodworking requirements. Our woodworking experts can give your production line an edge with our expert support.

Our team of research development comprised of more 10 highly skilled engineers is dedicated to creating new products that meet market needs offer tailored solutions that meet the specific requirements through constant product improvement research into technology ensure that stay ahead robust conveyor roller parts capabilities offer reliable efficient automation solutions breaking the boundaries of traditional technology leading technological trends This ensures optimal performance for every product develop